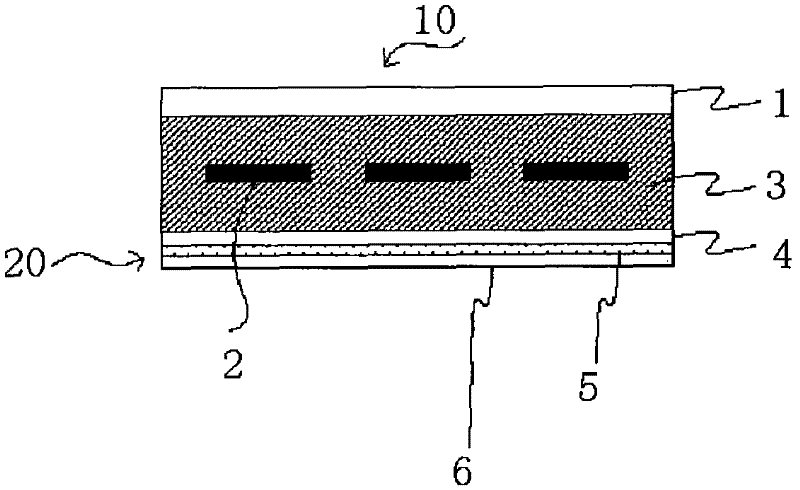

Rear panel for solar cell

A technology for solar cells and backplanes, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve problems such as wiring corrosion, changes in sealing materials, and reduction in output power of solar cell modules, so as to improve power generation efficiency and prevent deterioration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

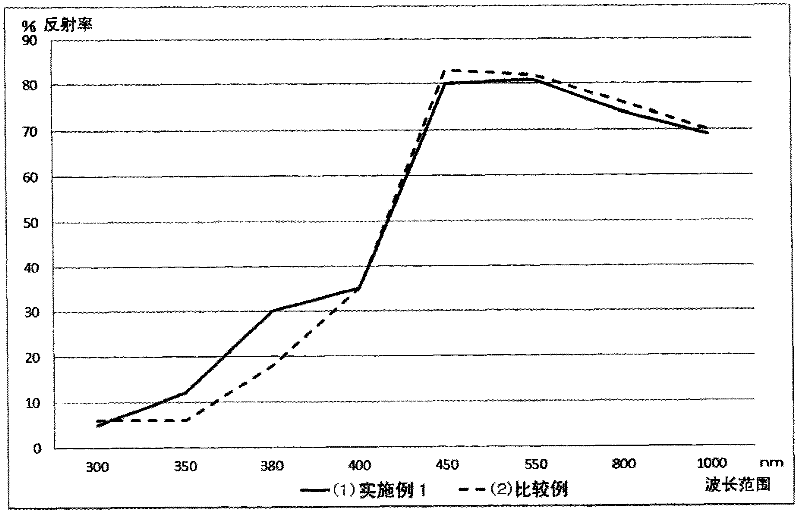

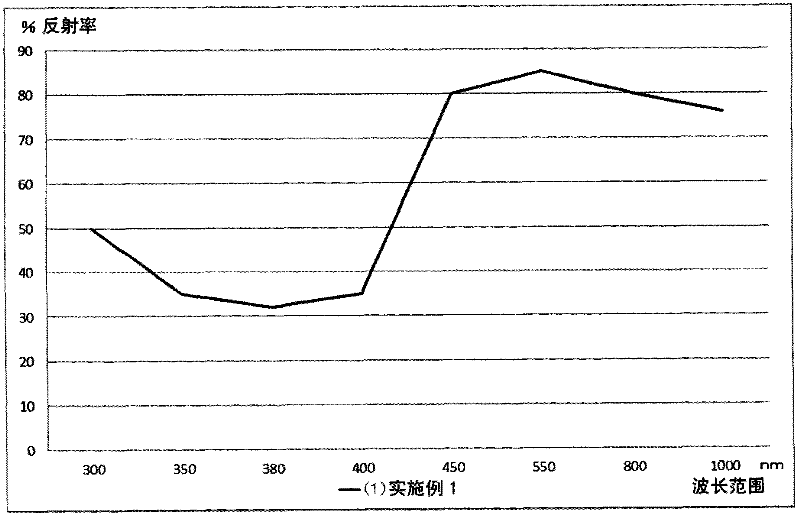

Embodiment 1

[0117] On one side of a polyethylene naphthalate (PEN) film (TEONEX manufactured by Teijin DuPont Films Japan Limited) with a thickness of 250 μm, a white resin composition was printed by screen printing so that the dry coating film was 30 μm. This was heat-cured at 120°C for 60 minutes to produce a white layer. Thereafter, a PEN film (TEONEX manufactured by Teijin DuPont Films Japan Limited) having a thickness of 50 μm was bonded by thermocompression to the surface of the white layer to prepare a test piece.

Embodiment 2

[0119] On one side of a PEN film (TEONEX manufactured by Teijin DuPont Films Japan Limited) with a thickness of 200 μm, a white resin composition was printed by screen printing so that the dry coating film was 30 μm, and it was heated at 120° C. for 60 minutes to make it Heat curing to produce a white layer. Thereafter, a PEN film (TEONEX manufactured by Teijin DuPont Films Japan Limited) having a thickness of 50 μm was bonded by thermocompression to the surface of the white layer to prepare a test piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com