Preparation method for near-infrared quantum clipping film of nano pyramid light trapping structure

A light-trapping structure and quantum tailoring technology, applied in the field of solar cells, can solve the problems of serious powder scattering, poor transparency, and restrictions on the practical application of solar cells, so as to improve conversion efficiency, reduce short-circuit current, and improve low working efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

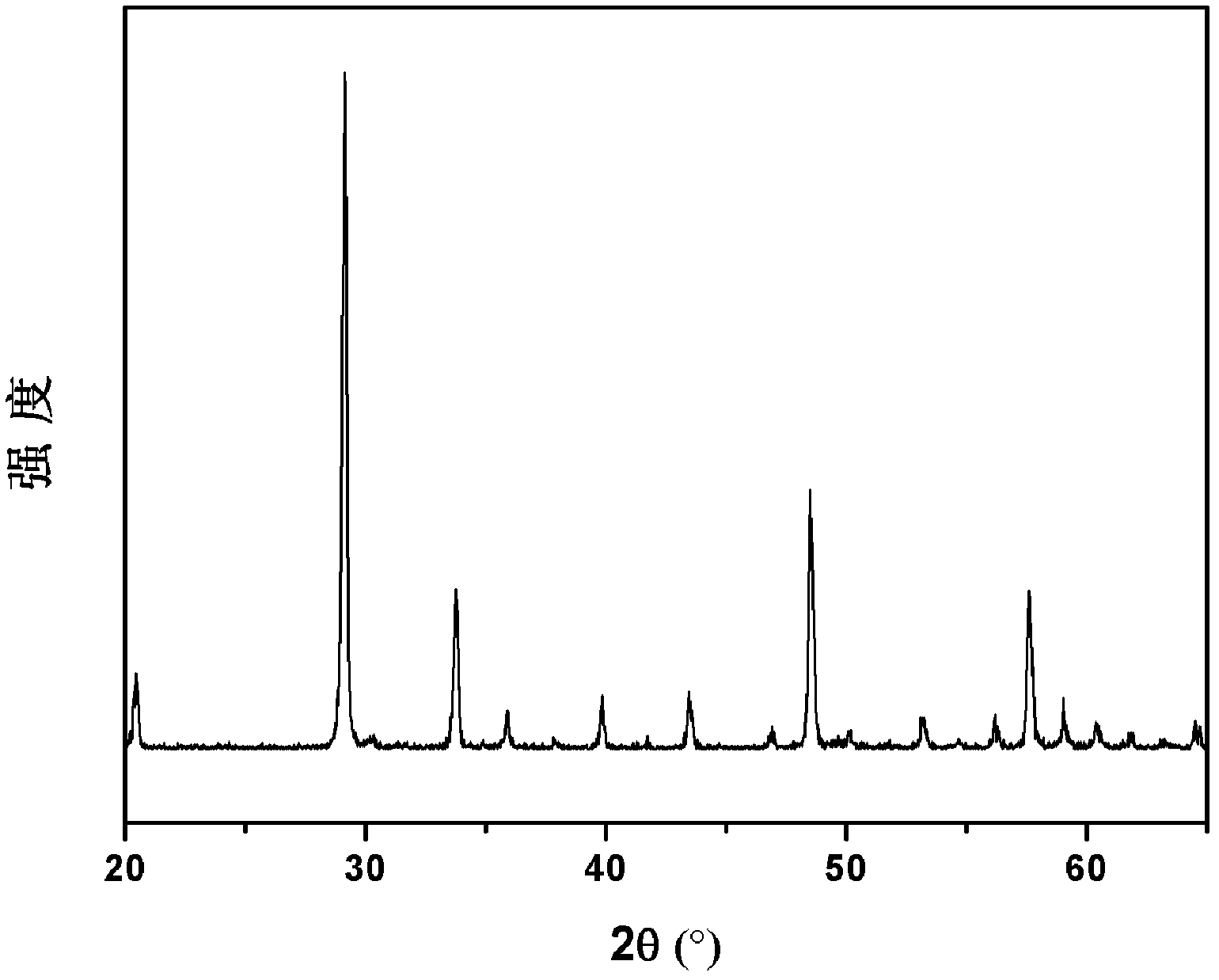

[0027] (1) in Y 2 o 3 The powder is mixed with an appropriate amount of Bi 2 o 3 and Yb 2 o 3 powder, where Bi 2 o 3 Powder mole fraction is 0.5%, Yb 2 o 3 The mole fraction of the powder is 2.5%, then ball milled and mixed, and dried at 80°C. Place the dried powder in a grinding tool and press it at 15MPa for 10 minutes to obtain a disc with a diameter of 2cm and a thickness of 5mm. The disc is calcined at 1100°C for 24h to make a ceramic target. The XRD pattern of its ceramic target material (see figure 1 ) exactly matches Y 2 o 3 PDF 41-1105 Diffraction Standard Spectrum.

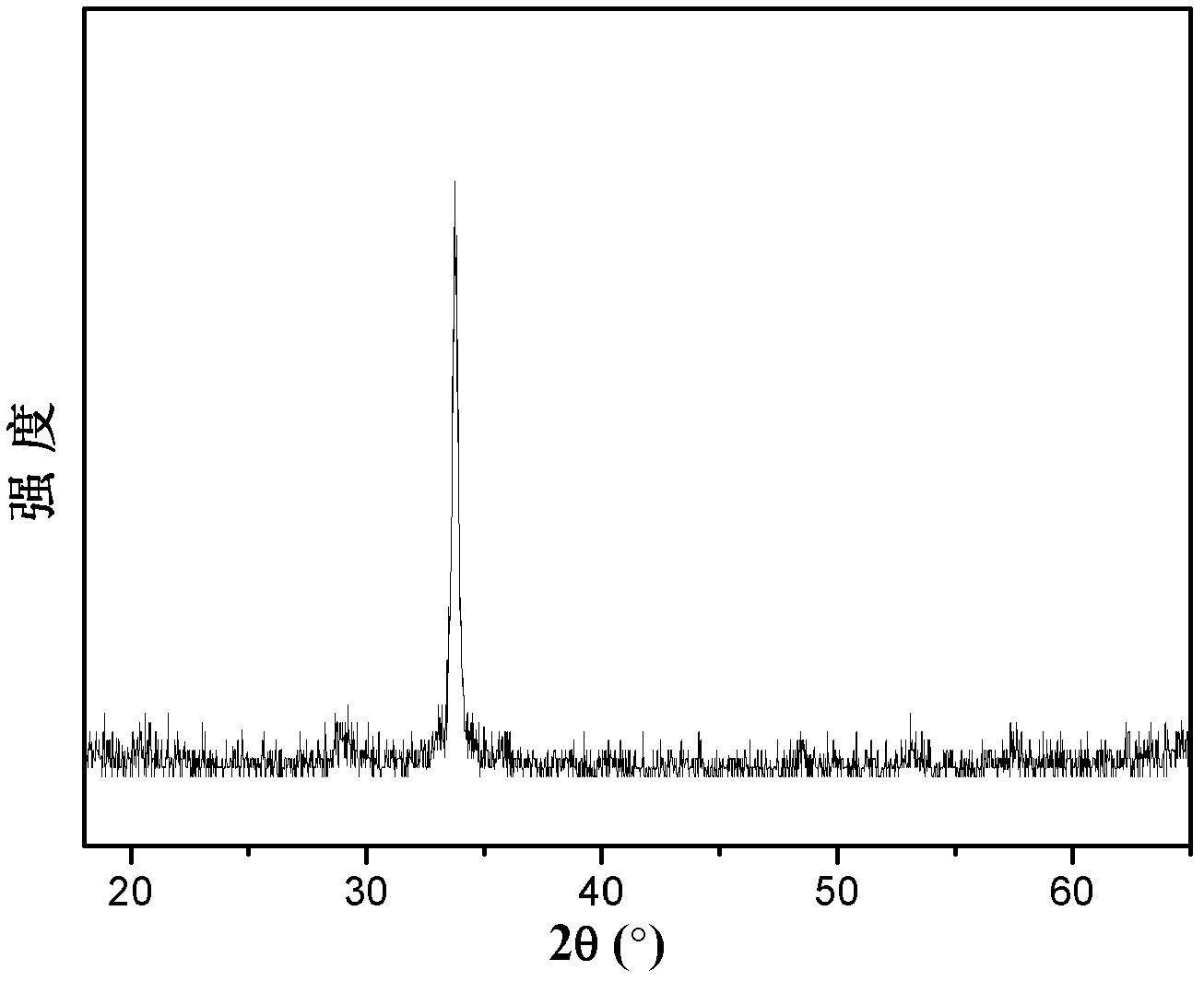

[0028] (2) Y made by step (1) 2 o 3 :Bi, Yb ceramic target, using laser pulse deposition method, using silicon wafer as substrate, passing O with a purity of 99.999% 2 , the substrate temperature is 700°C, the target-base distance is 8cm, the working pressure is 5Pa, the laser energy is 350mJ / pulse, and the deposition time is 60min. get pure phase Y 2 o 3 film, its XRD pattern is shown ...

Embodiment 2

[0030] in Y 2 o 3 The powder is mixed with an appropriate amount of Bi 2 o 3 and Yb 2 o 3 of powder, where Bi 2 o 3 Powder mole fraction is 1%, Yb 2 o 3 The mole fraction of the powder is 0.5%, then ball milled and mixed, and dried at 80°C. Place the dried powder in a grinding tool and press at 15MPa for 10 minutes to obtain a disc with a diameter of 2cm and a thickness of 5mm. The disc is calcined at 1200°C for 20h to make a ceramic target. The XRD pattern of its ceramic target is completely consistent with Y 2 o 3 PDF41-1105 Diffraction Standard Spectrum.

[0031] (2) Y made by step (1) 2 o 3 :Bi, Yb ceramic target, using laser pulse deposition method, using silicon wafer as substrate, passing O with a purity of 99.999% 2 , the substrate temperature is 800°C, the target-base distance is 5cm, the working pressure is 3Pa, the laser energy is 400mJ / pulse, and the deposition time is 60min. The XRD spectrum of the resulting film is shown in Figure 8 . Find that ...

Embodiment 3

[0033] (1) in Y 2 o 3 Add Bi to the powder 2 o 3 Powder and Yb 2 o 3 of powder, where Bi 2 o 3 Powder mole fraction is 0.25%, Yb 2 o 3 The molar fraction of the powder is 5%, then ball milled and mixed, and dried at 80°C. Place the dried powder in a grinding tool and press at 15MPa for 10 minutes to obtain a disc with a diameter of 2cm and a thickness of 5mm. The disc is calcined at 1300°C for 20h to make a ceramic target.

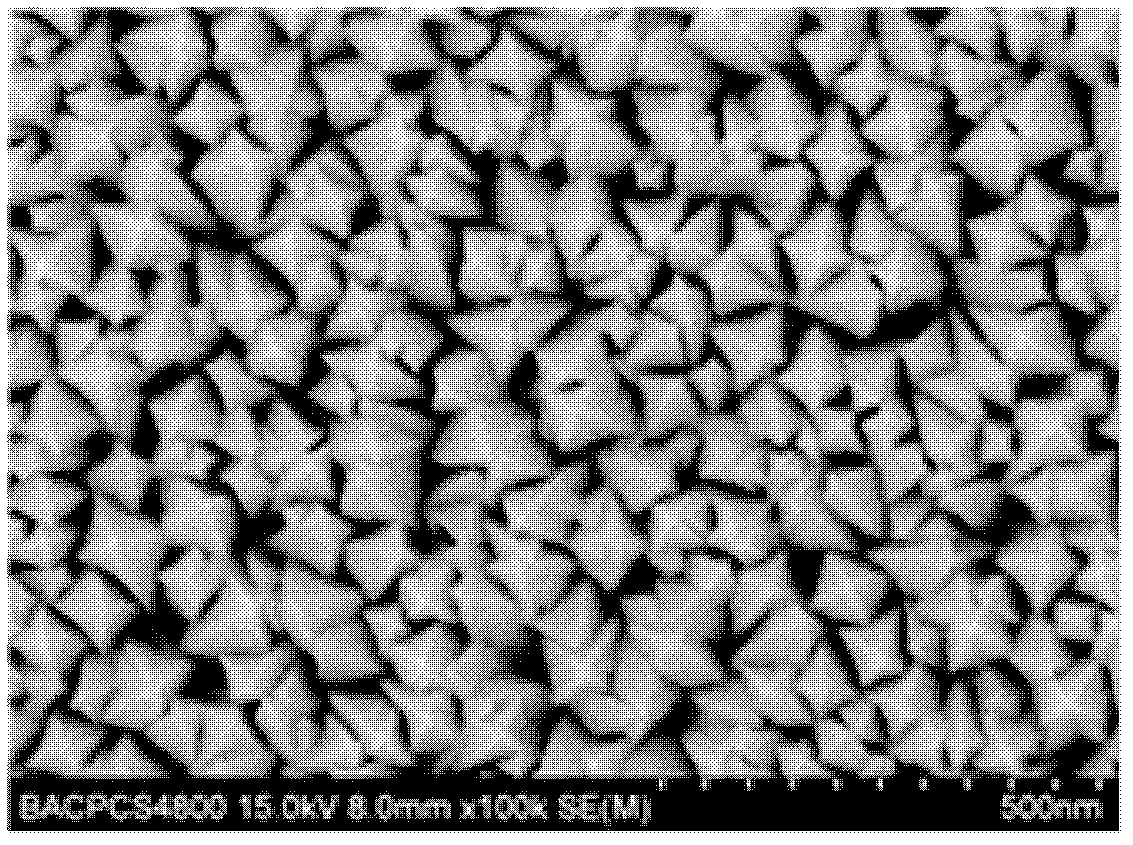

[0034] (2) Y made by step (1) 2 o 3 :Bi, Yb ceramic target, using laser pulse deposition method, using silicon wafer as substrate, passing O with a purity of 99.999% 2 , the substrate temperature is 500°C, the target-base distance is 6cm, the working pressure is 7Pa, the laser energy is 200mJ / pulse, and the deposition time is 60min. Its surface has a nano-pyramid structure (such as Figure 11 ), this film with a nano-pyramid structure has a good anti-reflection and light-trapping effect. Use FLS920 fluorescence spectrometer to measure the emi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com