New method for synthesizing porous layered LNMCO (333 material for short)

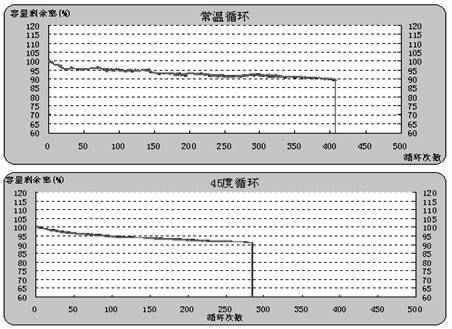

A technology of porosity and new method, applied in the field of porous layered LNMCO synthesis, can solve the problems of unstable structure, low discharge specific capacity, high price of cobalt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

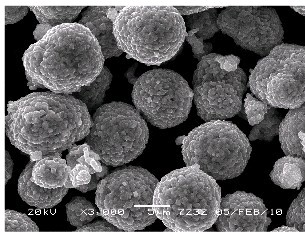

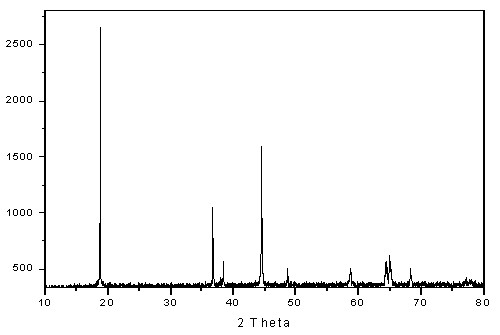

[0011] Prepare 0.1mol of Li (Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 , Accurately weigh the acetate of lithium, cobalt, nickel and manganese, lithium acetate: nickel acetate: manganese acetate: = 1.0: 0.333: 0.333: 0.333 and take the standard weight (to make Li excessive in the solution, add Li Excessive, to add Li 2 co 3 0.5mol mmol), respectively dissolved in 30-50ml of distilled water, mixed well and added to the total solution of fluxing system resorcinol concentration 0.1-0.2mol, formaldehyde concentration 0.10-0.3mol, fixed on the constant temperature water bath, The temperature is controlled at 60-80°C, stirred with a magnetic stirrer until it becomes a paste, transferred to a vacuum drying oven and dried at a constant temperature of 90°C for 12-24 hours. Transfer the dried preparation material into a crucible, place it in a muffle furnace, heat it up from room temperature to 800-900°C for calcination and keep it for 12-18 hours, then anneal, the cooling rate is 10°C / min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com