Toothbrush

A toothbrush and bristle technology, applied in the field of toothbrushes, can solve the problems of reduced usability, residual toothpaste, thickening of the brush head, etc., and achieve the effect of maintaining usability, preventing the bristles from breaking, and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A~5A

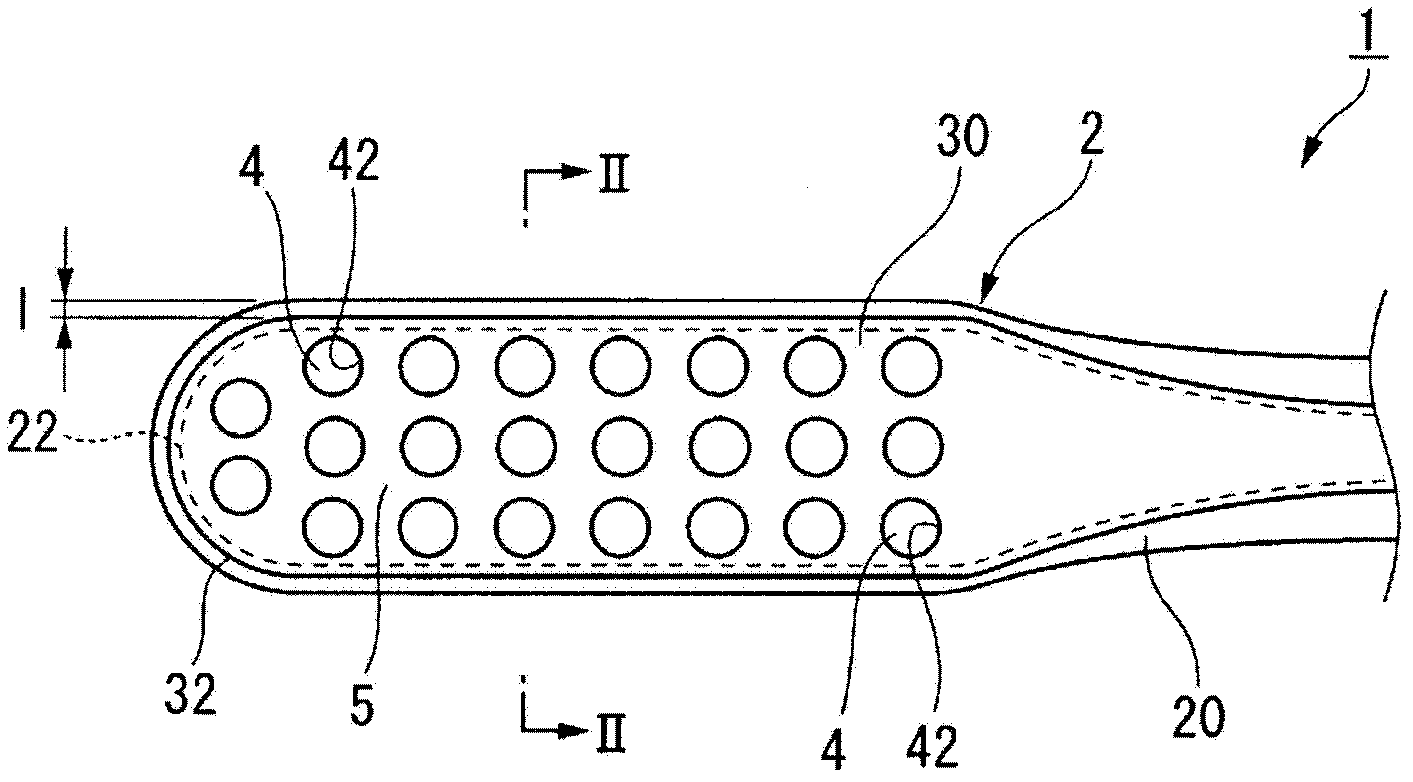

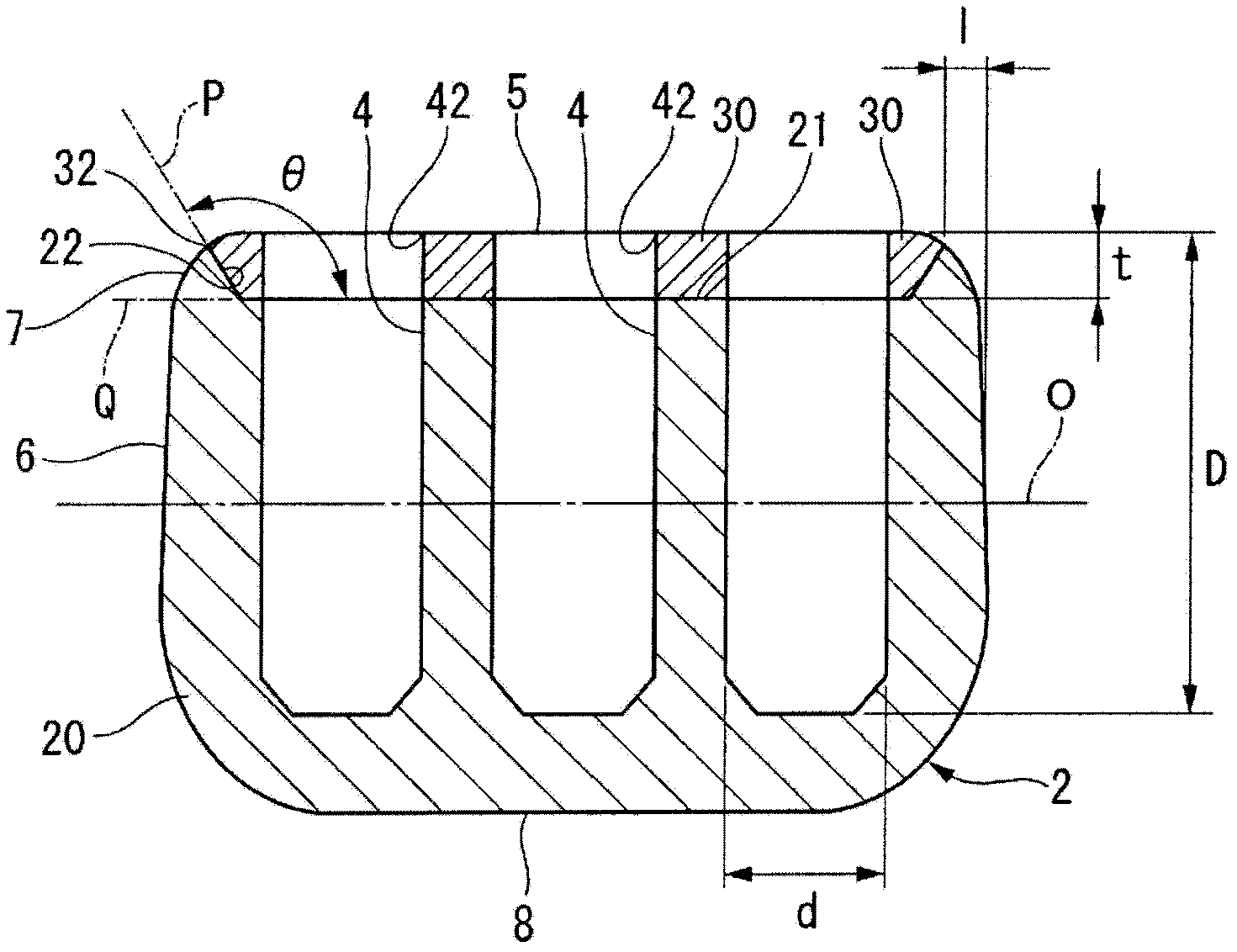

[0118] According to the specifications in Table 1A, the figure 1 The toothbrush 1 shown is the same toothbrush. PP was used as the primary resin constituting the base, and styrene elastomer resin (hardness 60) was used as the secondary resin constituting the buffer. Twenty bristles made by PTT (φ0.2mm) are made into tufts, and the tufts are folded into two with a tufting machine (manufactured by ZAHORANSKY) and put into 23 tufting holes together with flat wires (250shot / min) .

[0119] For the toothbrushes of each produced example, the easiness of lack of injection, burr generation, peeling, and flocking strength were evaluated, and the results are shown in Table 1A.

Embodiment 1B~8B

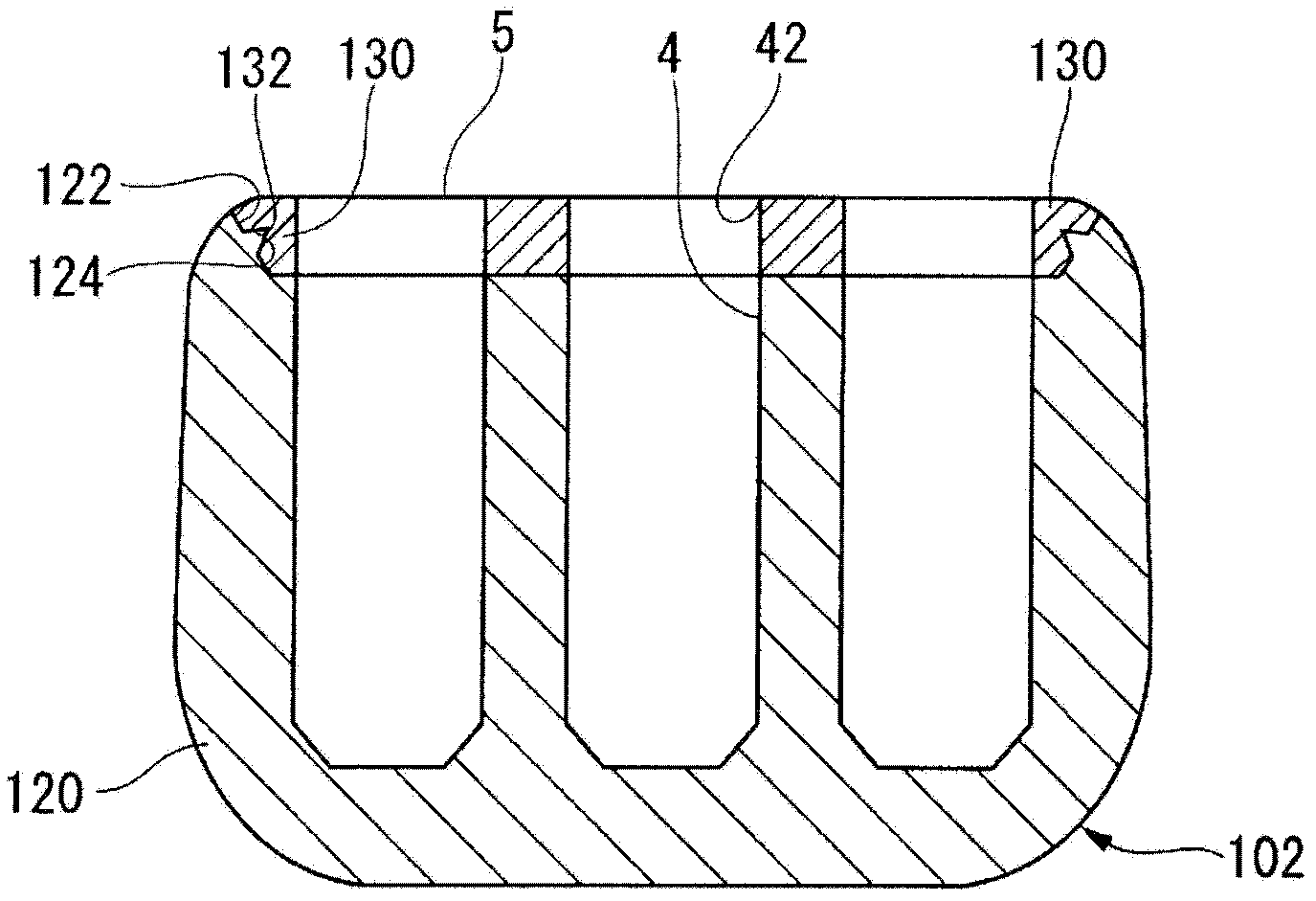

[0164] According to the specifications in Table 1B Figure 5 The toothbrush 301 shown is the same toothbrush (inclined surface 322: C surface). PP is used as the primary resin constituting the base, and styrene elastomer resin (hardness 60) is used as the secondary resin constituting the buffer. Twenty bristles made by PTT (φ0.2mm) were made into tufts, and the tufts were folded into two with a tufting machine (manufactured by ZAHORANSKY) and packed into 23 tufting holes together with flat wires (250shot / min) .

[0165] For the toothbrushes of each produced example, durability, bristle strength, head strength, and usability were evaluated, and the results are shown in Table 1B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com