Method for producing carbon solid segmented fishing poles

A fishing rod and carbon solid technology, which is applied in fishing rods, fishing, applications, etc., can solve the problems of complex preparation process and serious environmental pollution, and achieve the effect of simple process, no environmental pollution, and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

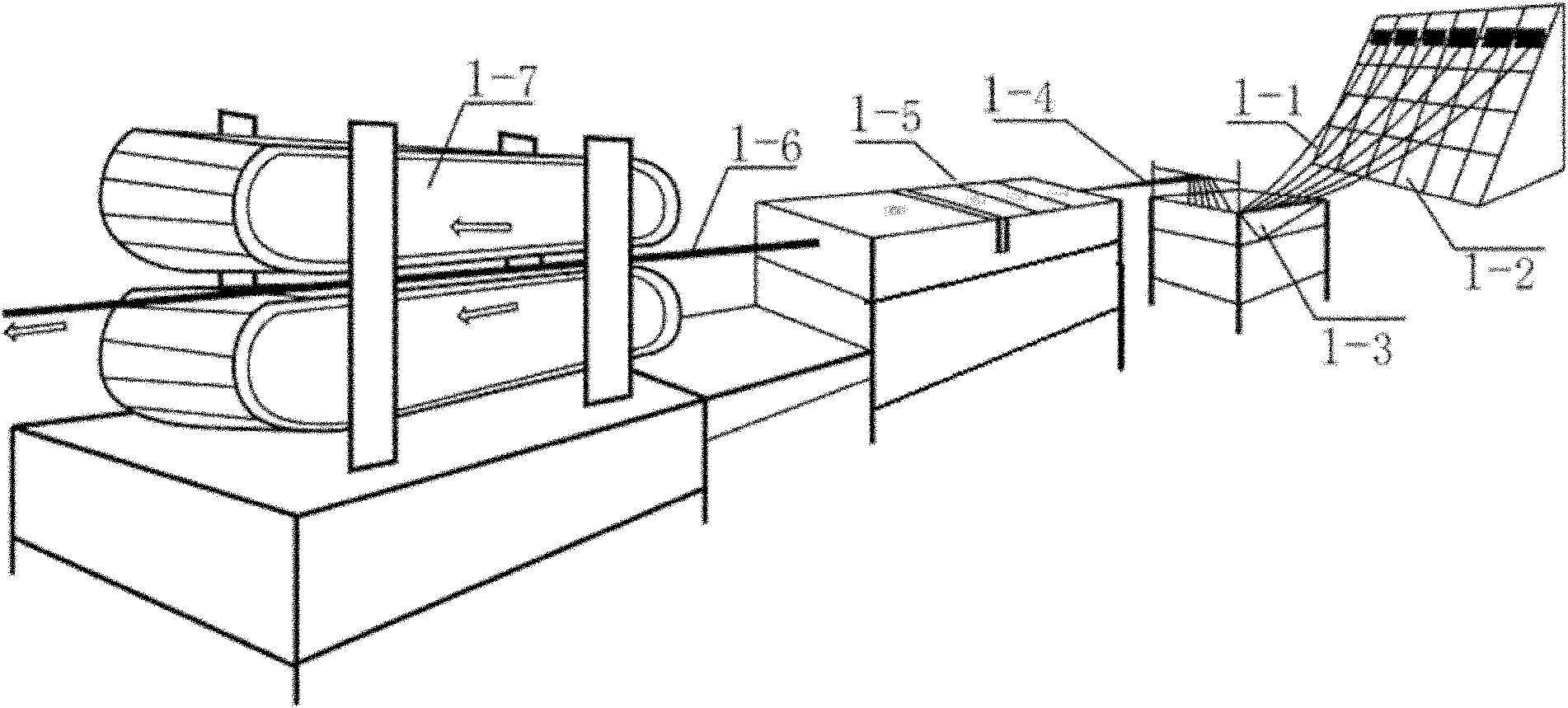

[0044] Embodiment 1 Carbon solid plug type fishing rod

[0045] 1. Production of carbon solid rods with diameters of 5.0mm and 7.0mm

[0046] Take out 20-23 strands of carbon yarn from the wire rack, (carbon fiber yarn (original Taiwan Taili (TAIRYFIL), 12K carbon fiber yarn TC35-12K4kg / roll)) and combine them into one strand, and then combine the combined two strands of carbon yarn Dip into the dipping tank to obtain two strands of glued ply carbon yarn.

[0047] The synthetic glue in the dipping tank is configured by conventional methods by 400g bisphenol A, 300g methyltetrahydrophthalic anhydride, 25g calcium carbonate, 25g silicone oil, and 8g N,N-dimethylaniline.

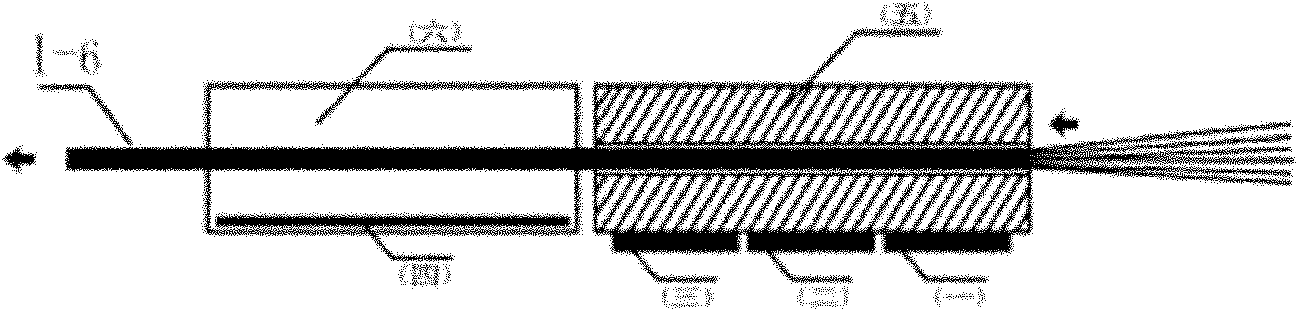

[0048] Next, the two strands of glued ply carbon yarns were respectively passed into the circular hole molds with diameters of 5.0 mm and 7.0 mm, and then the two plies of glued ply carbon yarns passed out were introduced into the chain rail.

[0049] In the heat curing zone, the temperature of the first stag...

Embodiment 2

[0057] Embodiment 2 carbon solid plug type fishing rod

[0058] 1. Production of carbon solid rods with diameters of 10.0mm and 20.0mm

[0059] Take 340-370 strands of carbon yarn (carbon fiber yarn (original TAIRYFIL), 12K carbon fiber yarn TC35-12K4kg / roll) from the cable rack and combine them into one strand respectively, and then dip the two strands of combined carbon yarn into Obtain two strands of glued ply carbon yarns in the dipping pool.

[0060] The synthetic glue in the dipping tank is composed of epoxy resin, curing agent, calcium carbonate, release agent and accelerator. Wherein, the epoxy resin is 600g of bisphenol A, the curing agent is 400g of methyl tetrahydrophthalic anhydride, the calcium carbonate is 28g, the release agent is 28g of silicone oil, and the accelerator is 10g of N,N-dimethylaniline.

[0061] Next, the joint ply carbon yarns with glued strands were respectively passed into the circular hole molds with diameters of 10.0mm and 20.0mm, and then ...

Embodiment 3

[0068] The production of embodiment 3 single joint type fishing rod

[0069] 1. Production of carbon solid rods with a diameter of 8.2mm

[0070] Take 52-60 strands of carbon yarn (original Taiwan Taili (TAIRYFIL), 12K carbon fiber yarn TC35-12K4kg / roll) from the cable rack and combine them into one strand, then dip the combined carbon yarns into the dipping tank to obtain a tape Glued ply carbon yarn.

[0071] The synthetic glue in the dipping tank is configured by 500g of bisphenol A, 400g of methyltetrahydrophthalic anhydride, 25g of calcium carbonate, 28g of silicone oil, and 10g of N,N-dimethylaniline.

[0072] Next, the glued ply carbon yarn is passed into a round hole mold with a diameter of 8.2 mm, and then the ply ply carbon yarn passed out is introduced into the chain rail.

[0073] In the heat curing zone, the temperature of the first stage was set at 175°C, the temperature of the second stage was 230°C, the temperature of the third stage was 250°C, and the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com