Catalyst for synthesizing methanol by taking multi-carbon sources in metallurgical fume as raw materials and preparation method of catalyst

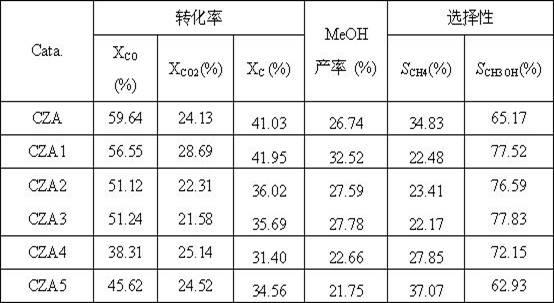

A technology for synthesizing methanol and catalysts, which is applied in the direction of catalyst activation/preparation, preparation of organic compounds, chemical instruments and methods, etc. It can solve the problems of many by-products, low selectivity of methanol, and low conversion rate of catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Cu:Zn:Al=5:4.5:0.5 in molar ratio, Ce:Zr molar ratio is 1.0:3.0, (CuO+ZnO+Al 2 o 3 ) and (CeO 2 +ZrO 2 ) with a mass ratio of 99.4:0.6, weigh Cu(NO 3 ) 2 ·3H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O, Zr(NO 3 ) 4 ·5H 2 O, Ce (NO 3 ) 3 ·6H 2 O was dissolved in deionized water to obtain a mixture with a concentration of 0.1 mol / L;

[0024] (2) At a reaction temperature of 70°C, titrate the above solution into Na with a concentration of 0.1mol / L 2 CO 3 In the solution, the pH of the solution was adjusted to be 7. After the titration was completed, the mixed solution was maintained at the reaction temperature to continue stirring for 60 minutes, then left to stand at the reaction temperature for 120 minutes to age the solution, and a solid precipitate was obtained after filtration;

[0025](3) Put the sediment into a polytetrafluoroethylene substrate reactor with a filling rate of 10%, and conduct a hydrothermal reaction under microwave conditions....

Embodiment 2

[0027] (1) Molar ratio Cu: Zn: Al=5.5:3:1.5, Ce: Zr molar ratio is 2.0:1.0, (CuO+ZnO+Al 2 o 3 ) and (CeO 2 +ZrO 2 ) with a mass ratio of 98.0:2.0, weigh Cu(NO 3 ) 2 ·3H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O, Zr(NO 3 ) 4 ·5H 2 O, Ce (NO 3 ) 3 ·6H 2 O was dissolved in deionized water to obtain a mixture with a concentration of 0.8 mol / L;

[0028] (2) At a reaction temperature of 50°C, titrate the above solution into Na with a concentration of 1.0mol / L 2 CO 3 In the solution, the pH of the solution was adjusted to be 7.5. After the titration was completed, the mixed solution was maintained at the reaction temperature to continue stirring for 30 minutes, then left to stand at the reaction temperature for 100 minutes to age the solution, and a solid precipitate was obtained after filtration;

[0029] (3) Put the precipitate into a polytetrafluoroethylene substrate reactor with a filling rate of 30%, and conduct a hydrothermal reaction under microwave condi...

Embodiment 3

[0031] (1) According to the molar ratio Cu: Zn: Al=6.5: 3.0, Ce: Zr molar ratio is 3.0: 2.0, (CuO+ZnO+Al 2 o 3 ) and (CeO 2 +ZrO 2 ) with a mass ratio of 9:1, weigh Cu(NO 3 ) 2 ·3H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O, Zr(NO 3 ) 4 ·5H 2 O, Ce (NO 3 ) 3 ·6H 2 O was dissolved in deionized water to obtain a mixture with a concentration of 1mol / L;

[0032] (2) At a reaction temperature of 80°C, titrate the above solution into Na with a concentration of 1.5mol / L 2 CO 3 In the solution, the pH of the solution was adjusted to be 8. After the titration was completed, the mixed solution was maintained at the reaction temperature to continue stirring for 40 minutes, then left to stand at the reaction temperature for 30 minutes to age the solution, and a solid precipitate was obtained after filtration;

[0033] (3) Put the precipitate into a polytetrafluoroethylene substrate reactor with a filling rate of 20%, and conduct a hydrothermal reaction under microwave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com