Catalyst for purifying nitric oxide, and preparation method thereof

A technology of nitrogen oxides and catalysts, which is applied in the field of nano-catalysis, can solve the problem that the overall effect of nitrogen oxides purification is not very ideal, and achieve the effects of improving anti-SO2 poisoning performance, inhibiting SO2 poisoning, and improving oxygen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) In the present invention, a solution containing 1wt% Cu will be prepared and loaded on the modified bauxite carrier with equal volume at room temperature. After drying at 120°C, impregnated with Ba(NO 3 ) 2 solution, the loading of Ba is 16wt%. Catalyst 1 is obtained after calcination at 400-550°C.

[0029] (2) Comparative sample Pt / Ba / Al 2 o 3 The preparation steps of: (i) Al 2 o 3 Synthesis of: Al(NO 3 ) 3 9H 2 O as raw material, dissolved in a certain amount of distilled water, with NH 3 ·H 2 O is a precipitant, centrifuged, dried, and roasted at 400-550°C. (ii) Load H separately 2 PtCl 6 ·6H 2 O and Ba(NO 3 ) 2 , and their loads are respectively: 1wt% and 16wt%, dried to take 20-30 mesh for later use.

Embodiment 2

[0031] (1) The present invention will prepare a solution containing 5wt% Cu, and load it on the modified bauxite carrier at room temperature with equal volume. After drying at 120°C, impregnated with Ba(NO 3 ) 2solution, the loading of Ba is 16wt%. Catalyst 2 is obtained after calcination at 400-550°C.

[0032] (2) Comparative sample Pt / Ba / Al 2 o 3 The preparation steps of: (i) Al 2 o 3 Synthesis of: Al(NO 3 ) 3 9H 2 O as raw material, dissolved in a certain amount of distilled water, with NH 3 ·H 2 O is a precipitant, centrifuged, dried, and roasted at 400-550°C. (ii) Load H separately 2 PtCl 6 ·6H 2 O and Ba(NO 3 ) 2 , and their loads are respectively: 1wt% and 16wt%, dried to take 20-30 mesh for later use.

Embodiment 3

[0034] (1) After modification, the bauxite is heat-treated at 130-170°C for 48h, 30%H 2 o 2 Treat for 10-24h, wash with distilled water to PH=7, dry, impregnate equal volume of 5wt% Cu solution and 16wt% Ba(NO 3 ) 2 , dried and calcined to obtain catalyst 3.

[0035] (2) Comparative sample Pt / Ba / Al 2 o 3 The preparation steps of: (i) Al 2 o 3 Synthesis: Al(NO 3 ) 3 9H 2 O as raw material, dissolved in a certain amount of distilled water, with NH 3 ·H 2 O is a precipitant, centrifuged, dried, and roasted at 400-550°C. (ii) Load H separately 2 PtCl 6 ·6H 2 O and Ba(NO 3 ) 2 , and their loads are respectively: 1wt% and 16wt%, dried, and take 20-30 meshes for later use.

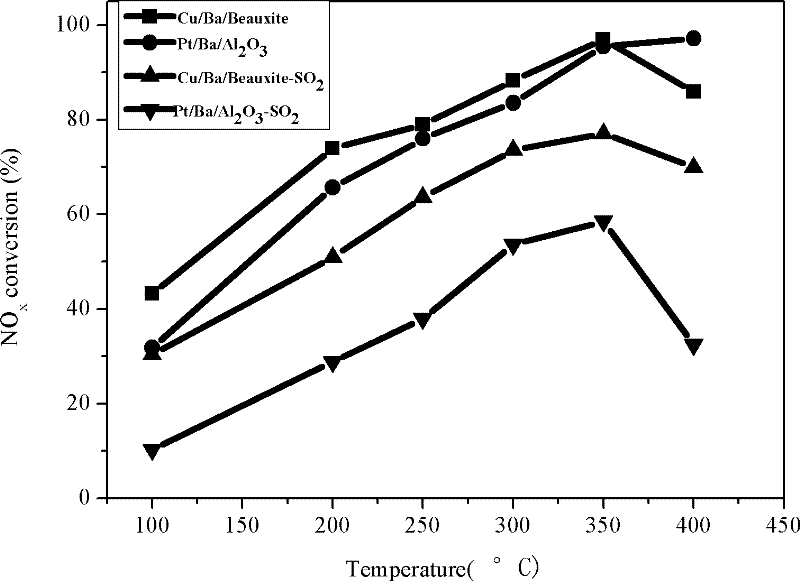

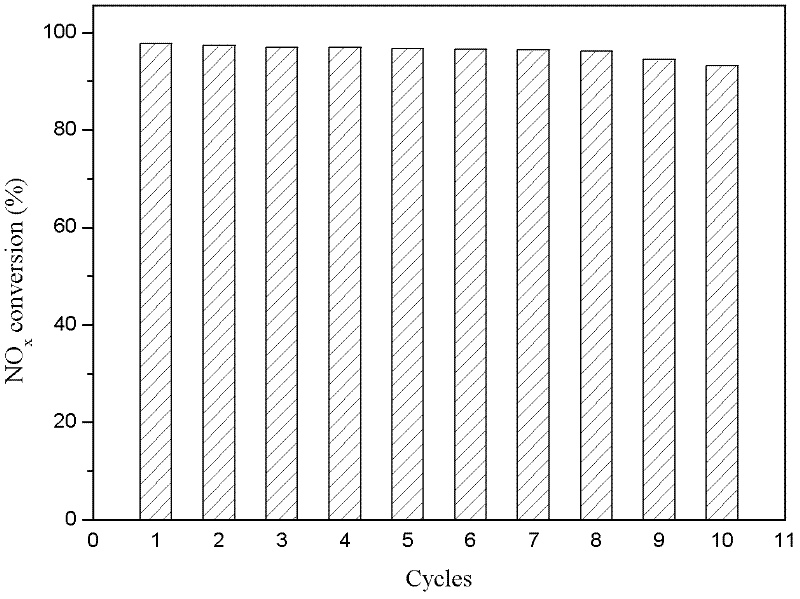

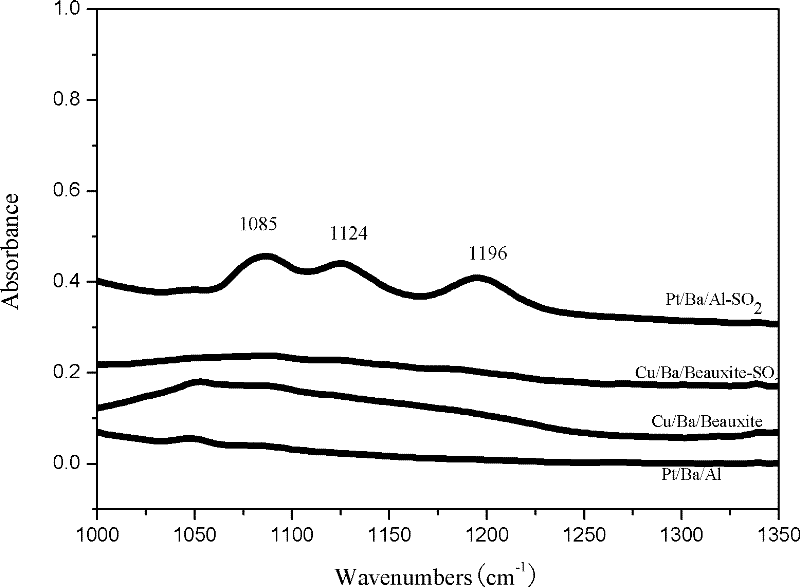

[0036] The performance of embodiment catalyst is evaluated below

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com