Detection integrated chip and detection method

An integrated chip and detection method technology, applied in the field of analysis and detection, can solve the problems of long detection cycle, complicated operation, expensive price, etc., and achieve the effect of short detection cycle, small size and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Blood Biochemical Analysis

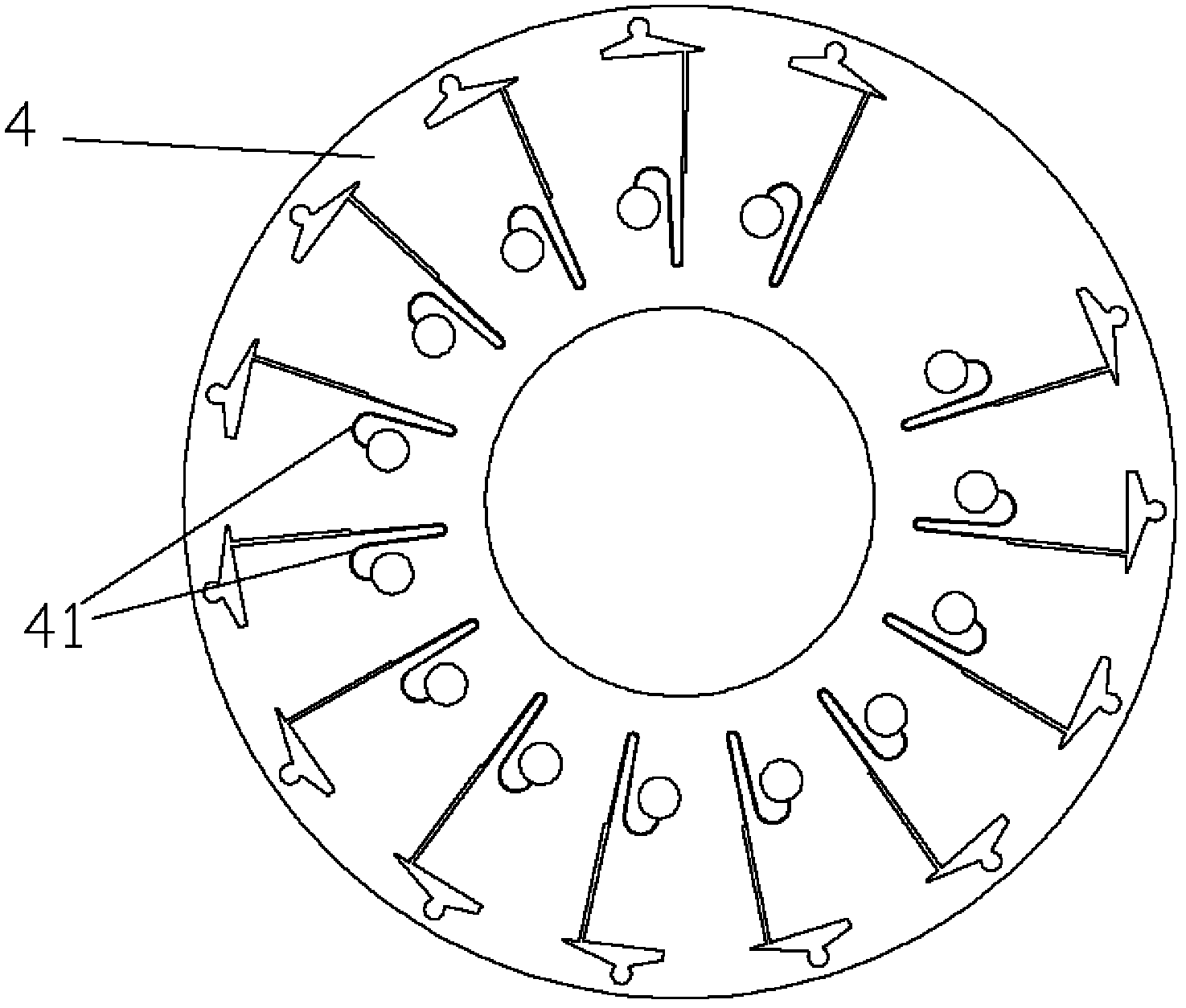

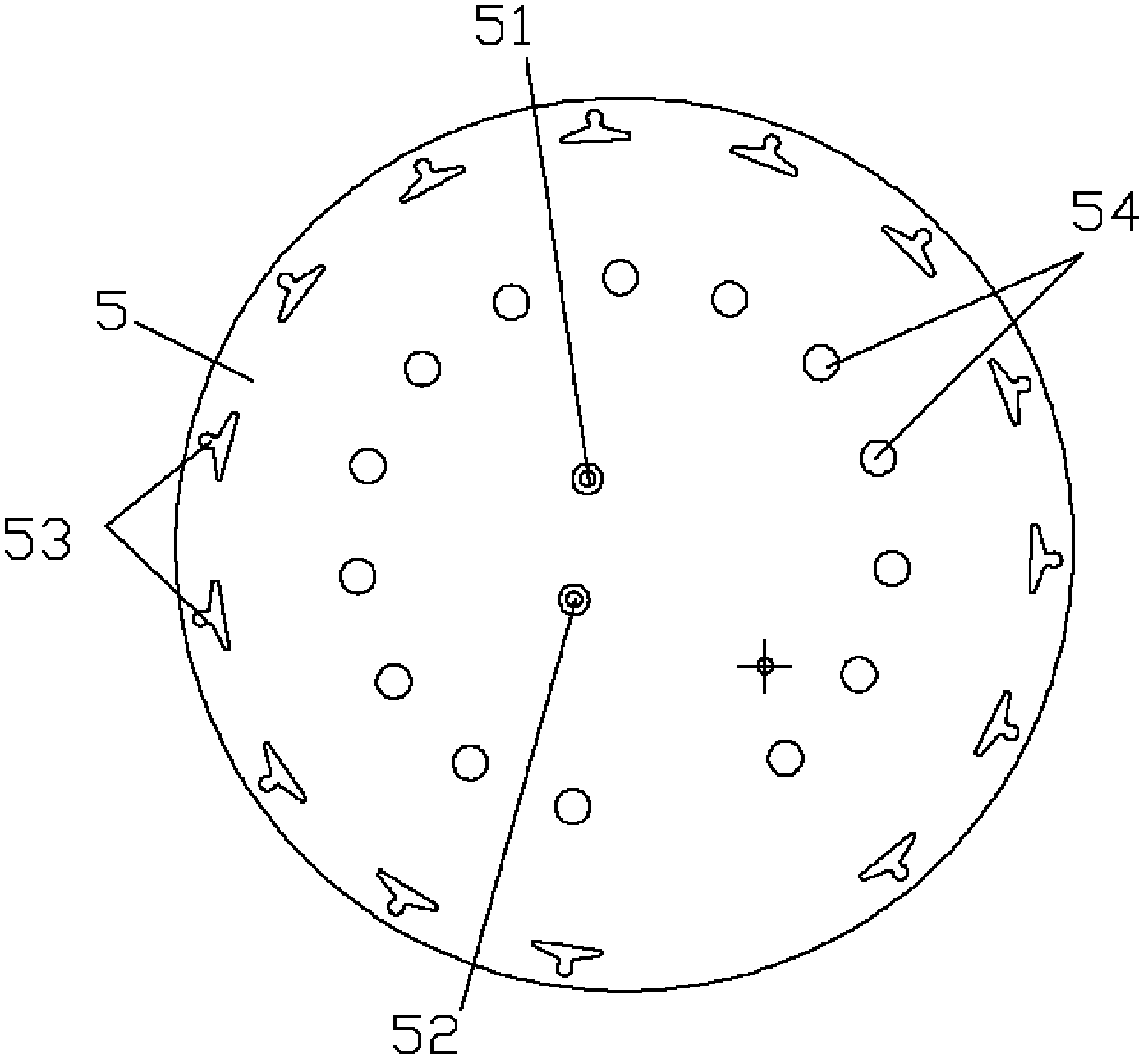

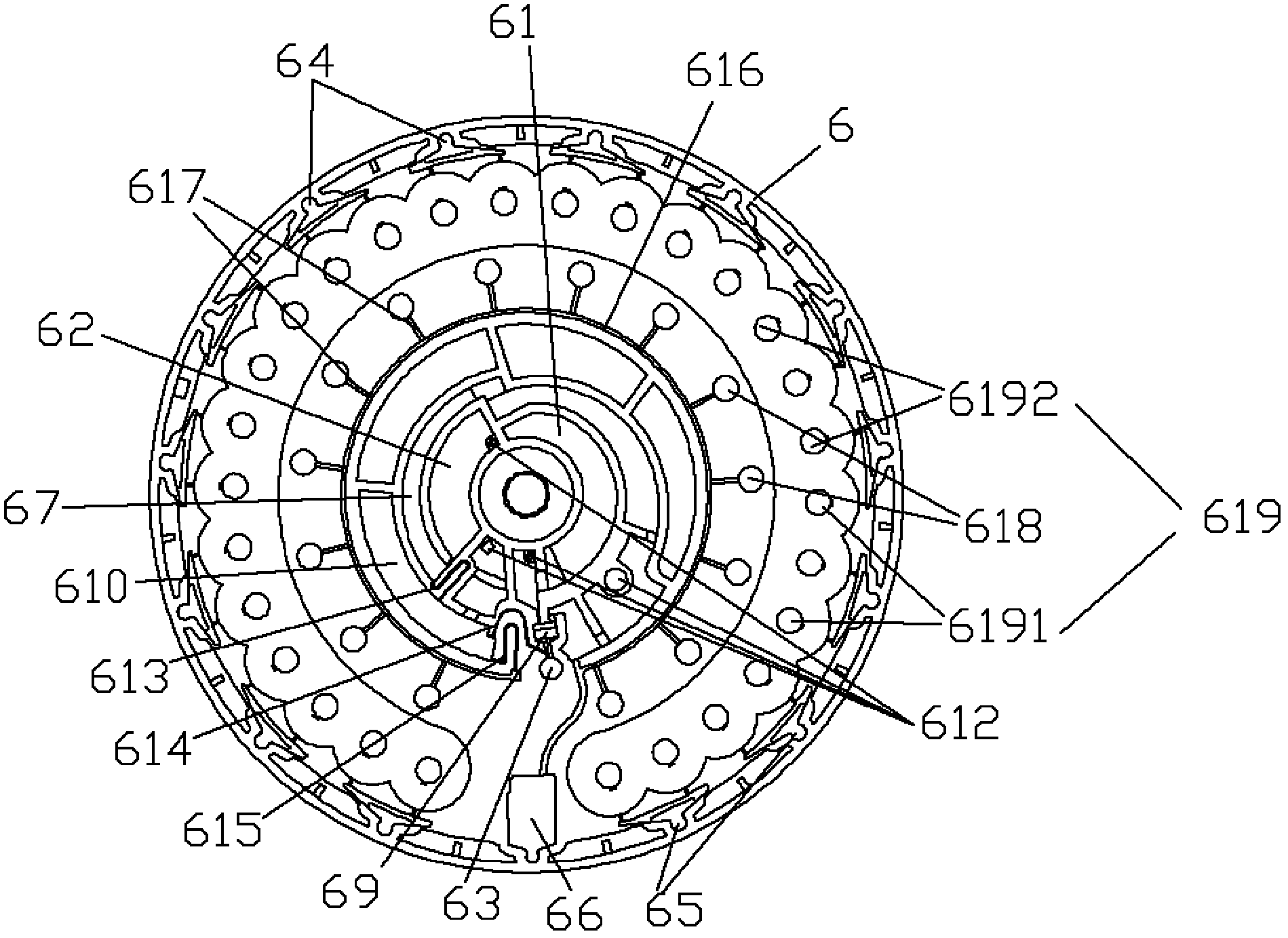

[0057] Such as figure 1 , 2 As shown in and 3, the detection integrated chip of the present invention is made of transparent plastic as a raw material by injection molding. The chip includes an upper layer 4, a middle layer 5 and a lower layer 6, wherein:

[0058] The lower surface of the upper layer 4 is provided with a flow channel 41 connecting the transition tank and the reaction detection tank.

[0059] The middle layer 5 is provided with through holes 51, 52 and another two groups of through holes 53, 54. The through hole 51 is used to add the sample, the through hole 52 is used to add the diluent, and the two groups of through holes 53 and 54 are respectively connected with the reaction on the lower layer. The detection groove 64 corresponds to the transition groove 618 .

[0060] The lower layer 6 is provided with a sample tank 61, a diluent tank 62, a liquid storage tank 63, a reaction detection tank 64, a self-test t...

Embodiment 2

[0073] Embodiment two: water quality detection

[0074] Using transparent plastic as raw material, the chip is made by injection molding, and pre-installed in the first reagent tank 6191 and the second reagent tank 6192 (needed by the double reagent method) for detecting organic matter (such as phenol) and heavy metal ions (such as lead, copper, iron), pesticide residues (such as organophosphorus) reagents. Take 1 ml of water sample and add it into the sample tank 61 . If dilution is required, the dilution liquid is injected into the dilution tank 62 . Fix the chip on the motor, start the motor and start to rotate. The steps of sample delivery, separation, and reaction detection are similar to those in Example 1.

Embodiment 3

[0075] Example 3: Food Hygiene Testing

[0076] Using transparent plastic as raw material, the chip is made by mold injection, and pre-installed in the first reagent tank 6191 and the second reagent tank 6192 (needed by the double reagent method) to detect microorganisms (such as E. coli), additives ( Reagents such as glucoamylase preparations), pesticide residues (such as organophosphorus, carbamate pesticides), pollutants (such as inorganic arsenic, formaldehyde, cyanide, nitrite), proteins, etc. Liquid samples can be directly sampled and added to the chip. Solid samples need to be crushed, dissolved in liquid, and added to the chip. In particular, various extraction techniques can be used to extract the substance to be tested from the food, and then added to the chip for detection. The detection method is the same as in Example 1.

[0077] Of course, before the liquid reaction reagent sealed by the film flows out of the reagent tank, small holes can also be punched in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com