Online control system and control method for surface quality of continuous casting billet

A surface quality and control system technology, applied in the field of continuous casting slab quality detection and control in iron and steel metallurgy, can solve problems such as increased production costs, reduced production efficiency, waste of manpower and material resources, etc., to reduce production costs and energy consumption, improve Yield, product quality, and production efficiency improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the content of the present invention will be further clarified below in conjunction with the embodiments, but the content of the present invention is not limited to the following embodiments. Those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms are also within the scope of the claims listed in this application.

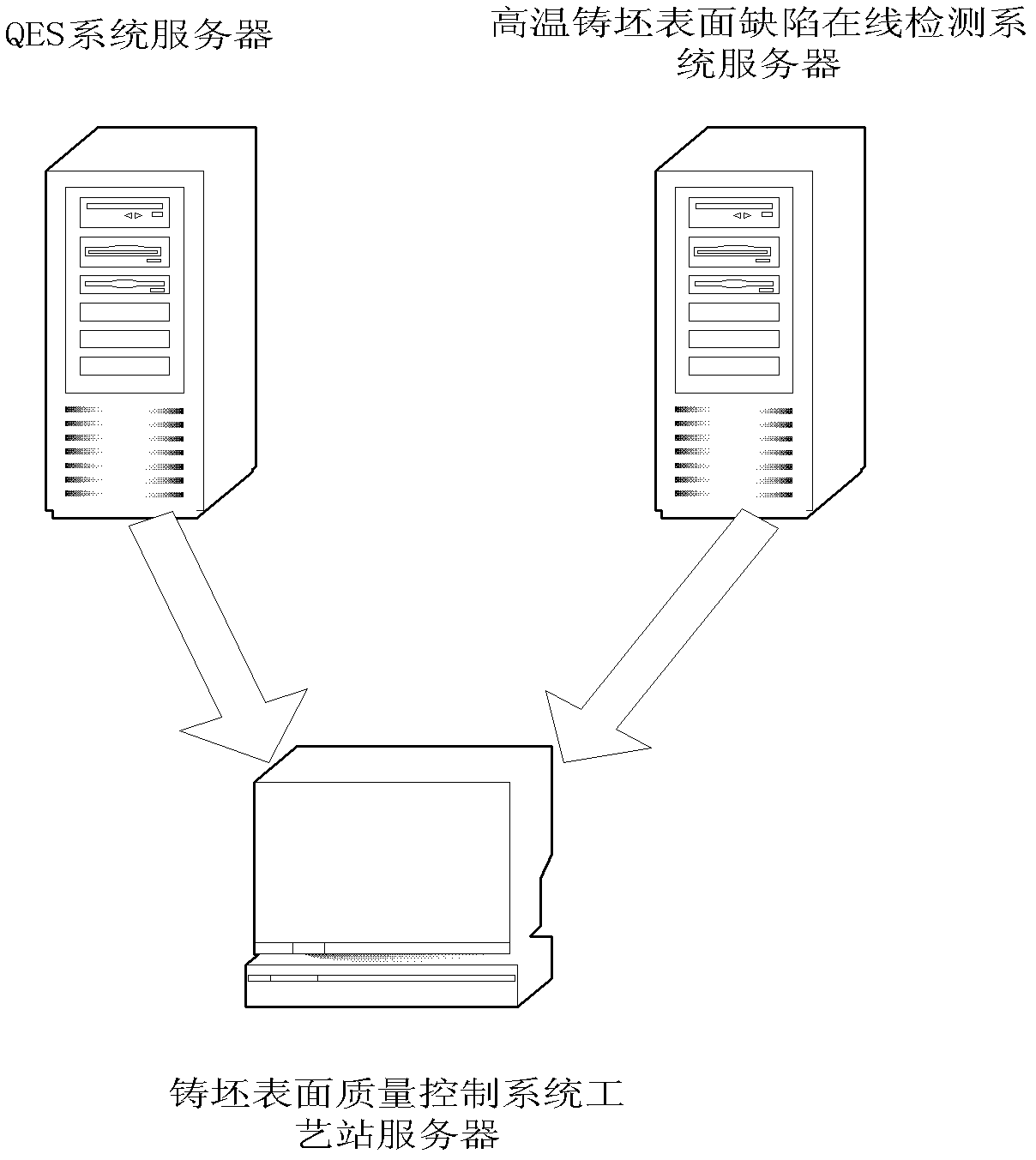

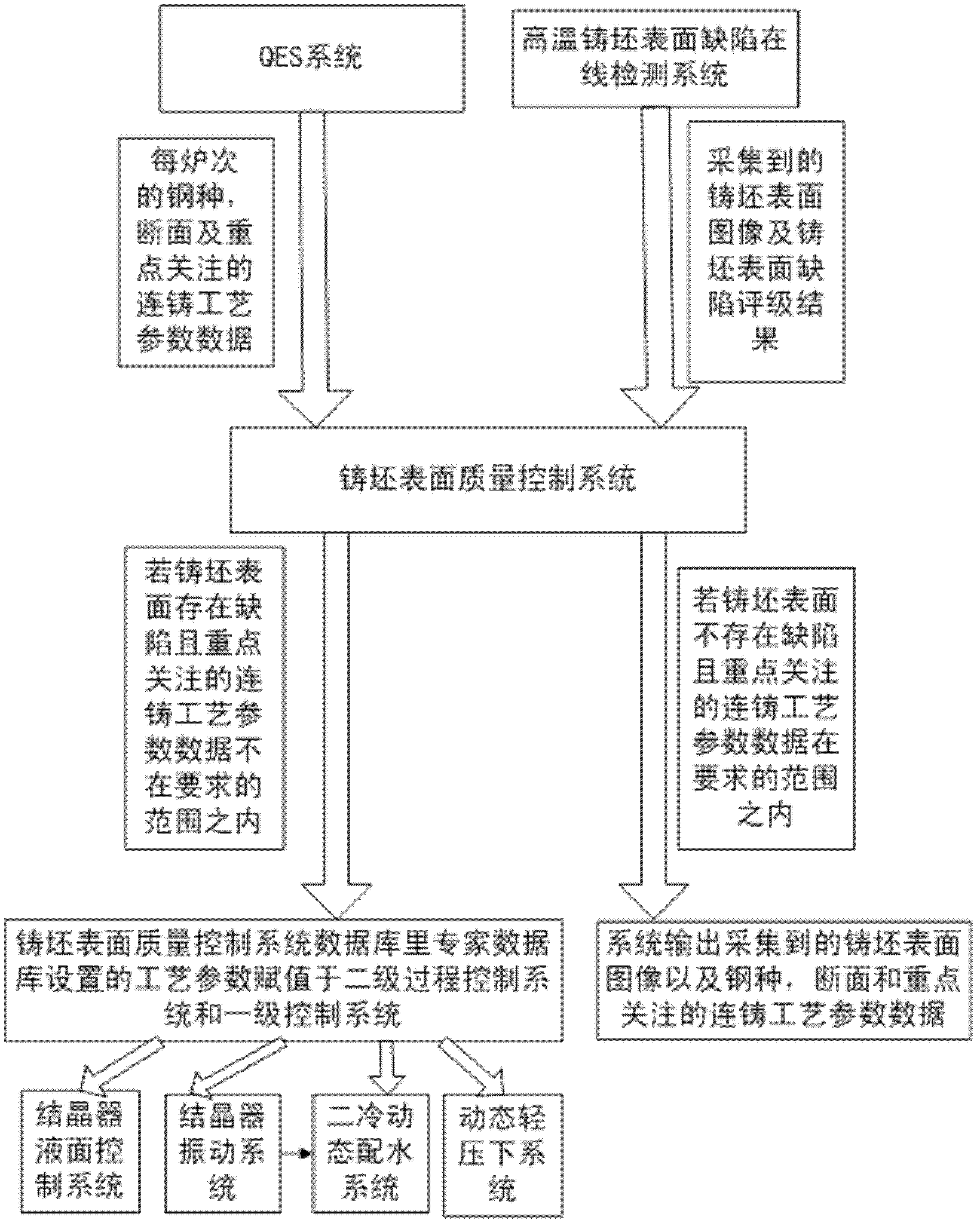

[0030] Such as figure 1 As shown, the online control system for continuous casting slab surface quality provided by the embodiment of the present invention mainly includes three parts: slab quality judgment and product quality diagnosis system (QES) server, high-temperature slab surface defect online detection system server and slab Surface quality control system craft station server.

[0031] Here, first briefly introduce the slab quality judgment and product quality diagnosis system and the high-temperature continuous casting slab surface defect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com