High-speed digital printing processing system based on embedded processor

An embedded processor, high-speed digital printing technology, applied in the direction of digital output to printing units, printing, printing devices, etc., can solve the problem of real-time processing of printing images with large data volume, inability to exert the precision of digital printing machines, and inability to be widely used and other problems, to achieve the effect of improving data throughput, improving scalability, and reducing data transmission delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the present invention more specifically, the technical solution and working process of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

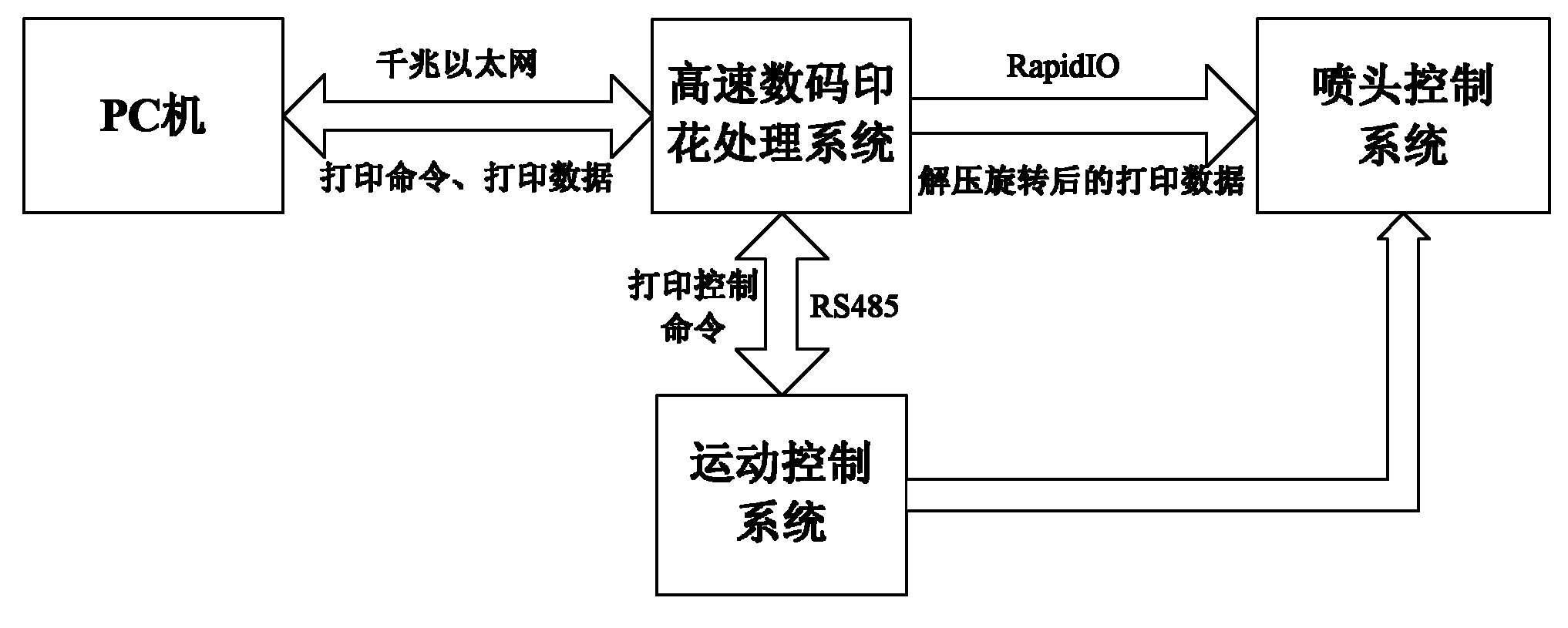

[0028] Such as figure 1 As shown, the principle of high-speed digital printing is as follows: First, receive the print image data and print command transmitted by the PC through Gigabit Ethernet; then analyze the print command and send it to the motion control system to decompress and rotate the print data Finally, it is sent to the nozzle control system; finally, the nozzle of the printing machine prints the image to be printed onto the carrier according to the printing control command.

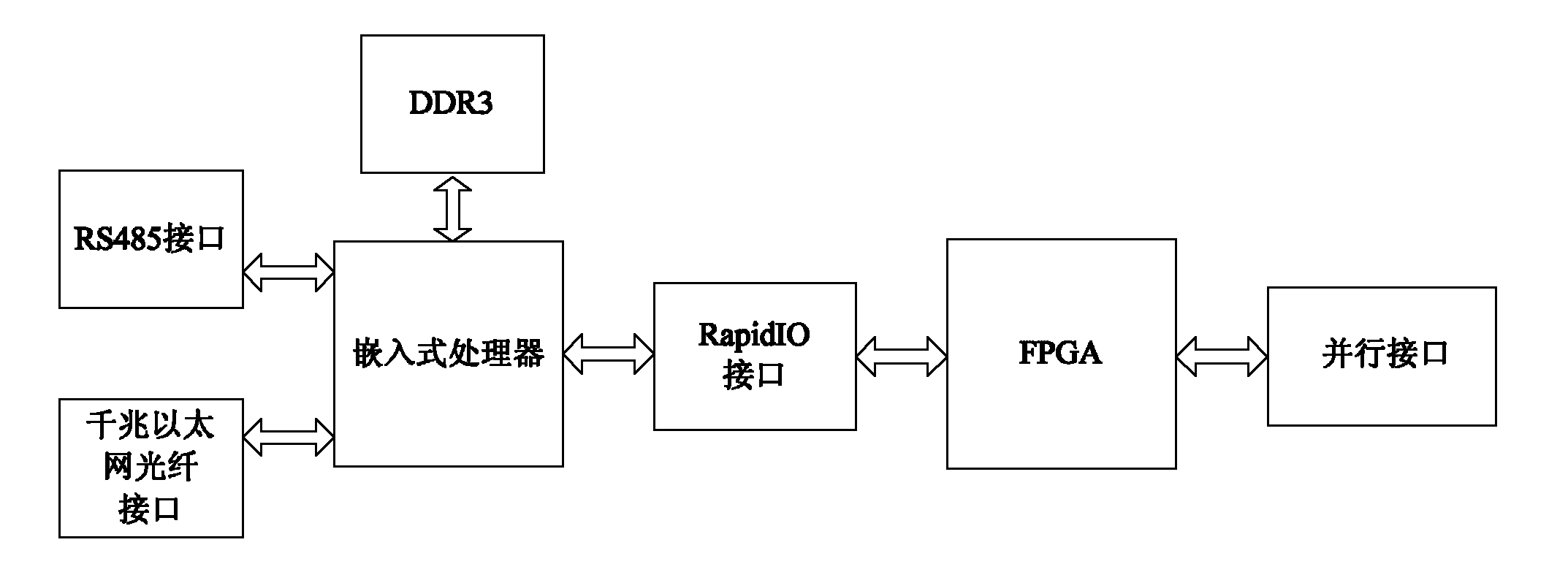

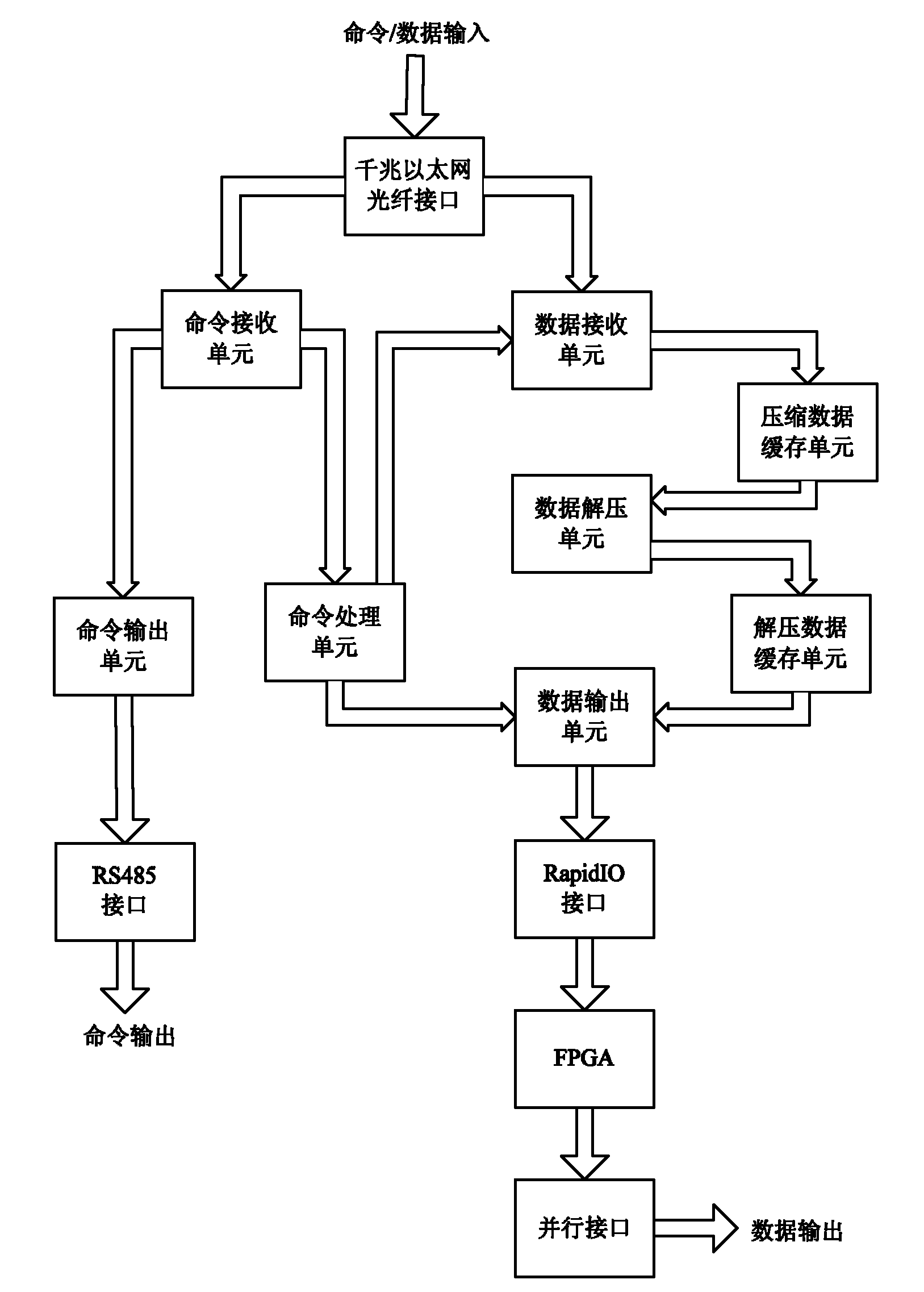

[0029] Such as figure 2 with 3 As shown, a high-speed digital printing processing system based on an embedded processor, including Gigabit Ethernet optical fiber interface, RS485 interface, RapidIO interface, embedded processor and FPGA; wherein: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com