Production method of granularity-controllable titanium dioxide

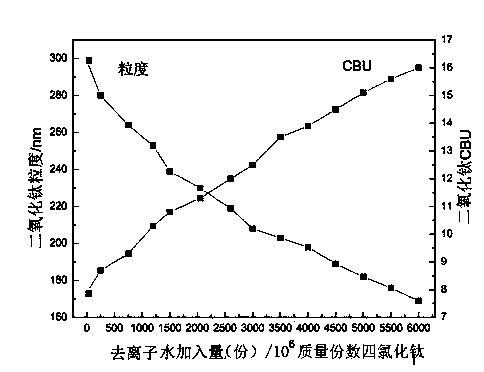

A technology of titanium dioxide and production method, which is applied in the production field of titanium dioxide with controllable particle size, can solve the problems of limited control range and high cost of aluminum trichloride, and achieve the effects of improving crystal conversion rate, low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

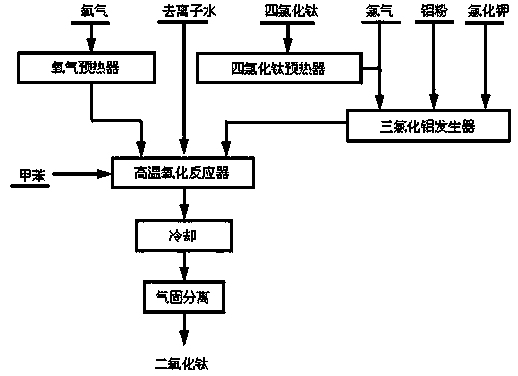

[0020] Under the pressure of 200kPa, titanium tetrachloride is preheated to 490°C by titanium tetrachloride preheater, and oxygen is preheated by oxygen preheater to 900°C, respectively introduced into the high temperature oxidation reactor; burn with toluene The heat generated preheats the hot oxygen to 1800°C in the high temperature oxidation reactor for the second time, so that titanium tetrachloride and oxygen undergo a gas-phase oxidation reaction, and at the same time add aluminum trichloride, potassium chloride and deionized water, of which four The mass ratios of titanium chloride to aluminum trichloride, potassium chloride and deionized water are 1000:15, 1000:3 and 1000:6 respectively (the amount of deionized water is controlled by a metering pump), such as figure 2 Shown, the addition mode of aluminum trichloride is to react in the aluminum trichloride generator with aluminum powder and chlorine, and the aluminum trichloride of generation and titanium tetrachloride ...

Embodiment 2

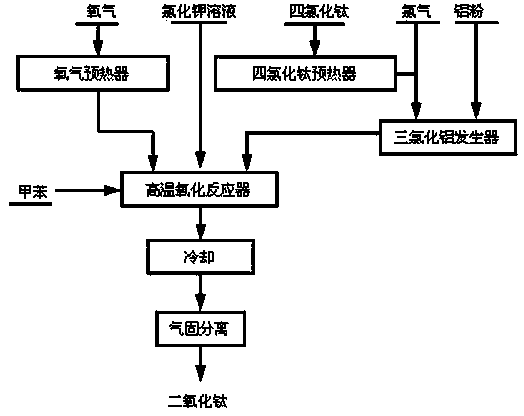

[0022] Under the pressure of 800kPa, preheat titanium tetrachloride to 550°C and oxygen to 750°C, and introduce them into the high temperature oxidation reactor respectively; use the heat generated by the combustion of toluene to heat the oxygen in the high temperature oxidation reactor twice Preheat to 1500°C to make gas-phase oxidation reaction between titanium tetrachloride and oxygen, and add aluminum trichloride, potassium chloride and deionized water at the same time, among them, titanium tetrachloride and aluminum trichloride, potassium chloride, deionized water The mass ratio of ionized water is 1000:2.5, 1000:0.015, 1000:0.095 (the amount of deionized water is controlled by a metering pump), such as figure 1 Shown, the addition mode of aluminum trichloride is to react in the aluminum trichloride generator with aluminum powder and chlorine, and the aluminum trichloride of generation and titanium tetrachloride airflow are jointly introduced in the oxidation reactor; The...

Embodiment 3

[0024] Under the pressure of 400kPa, preheat titanium tetrachloride to 520°C and oxygen to 760°C, and introduce them into the high temperature oxidation reactor respectively; use the heat generated by the combustion of toluene to heat the oxygen twice in the high temperature oxidation reactor Preheat to 1650°C to make gas-phase oxidation reaction between titanium tetrachloride and oxygen, and add aluminum trichloride, potassium chloride and deionized water at the same time, among them, titanium tetrachloride and aluminum trichloride, potassium chloride, deionized water The mass ratios of ionized water are 1000:10, 1000:1, and 1000:0.095 (the amount of deionized water is controlled by a metering pump), such as figure 1 Shown, the addition mode of aluminum trichloride is to react in the aluminum trichloride generator with aluminum powder and chlorine, and the aluminum trichloride of generation and titanium tetrachloride airflow are jointly introduced in the oxidation reactor; Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com