Supercritical water treatment device for treating organic waste and treatment method for organic waste

A technology of organic waste and treatment equipment, applied in the field of supercritical water treatment equipment, can solve problems such as difficult daily operation and maintenance, complex structure, etc., and achieve the effect of convenient daily operation and maintenance, avoiding direct contact, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

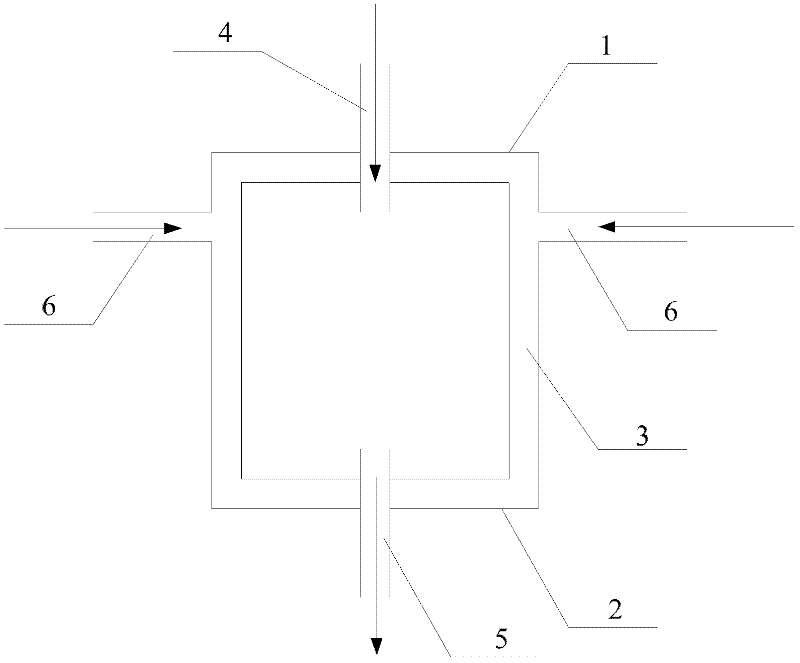

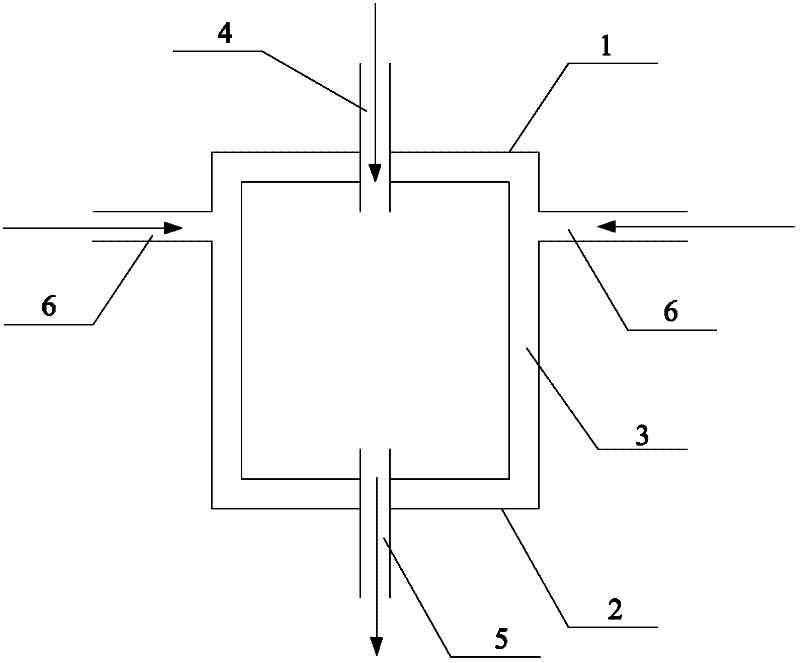

[0023] The invention provides a supercritical water treatment device for organic waste treatment, comprising:

[0024] A double-layer reactor composed of a pressure-resistant shell and an inner wall provided with micropores, the inner wall encloses a reaction chamber, and the pressure-resistant shell and the inner wall form a cavity;

[0025] A feed pipe and a discharge pipe respectively penetrating through the pressure-resistant shell and the inner wall, and communicating with the reaction chamber;

[0026] A high-pressure gas inlet pipe that passes through the pressure-resistant shell and communicates with the cavity.

[0027] In the present invention, the preheated mixture composed of organic waste and water is pumped into the reaction chamber of the above-mentioned treatment device through a high-pressure pump; Air, organic waste and oxygen in the air undergo a violent oxidation reaction in supercritical water to decompose the organic waste. In the present invention, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com