Device for preparing cement water reducing agent by physical method

A physical method and technology of water reducing agent, which is applied in the field of decarbonized ash, that is, cement water reducing agent, can solve the problems of complex process, many preparation conditions and tediousness, so as to improve the preparation efficiency, reduce dust pollution, increase the The effect of selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

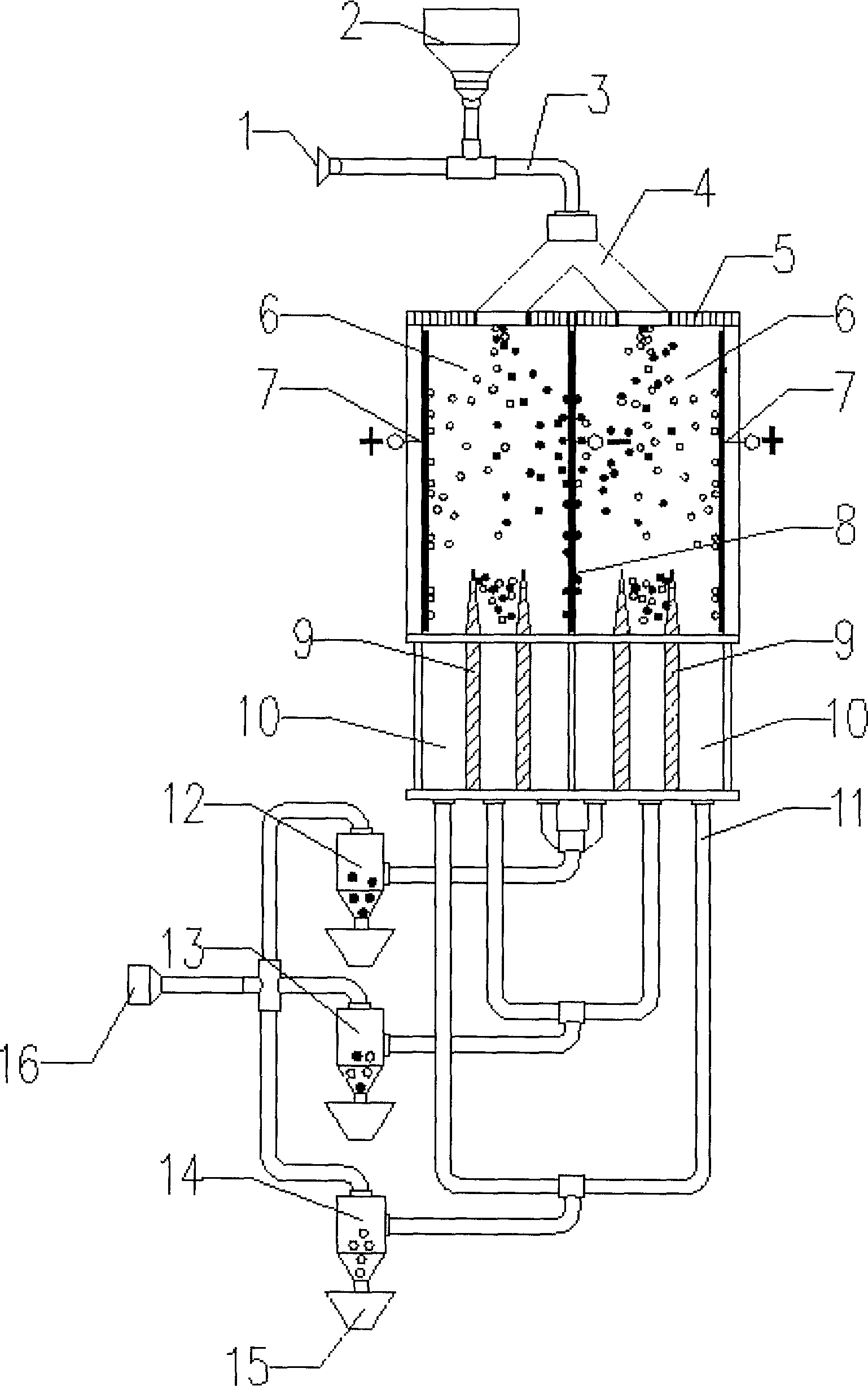

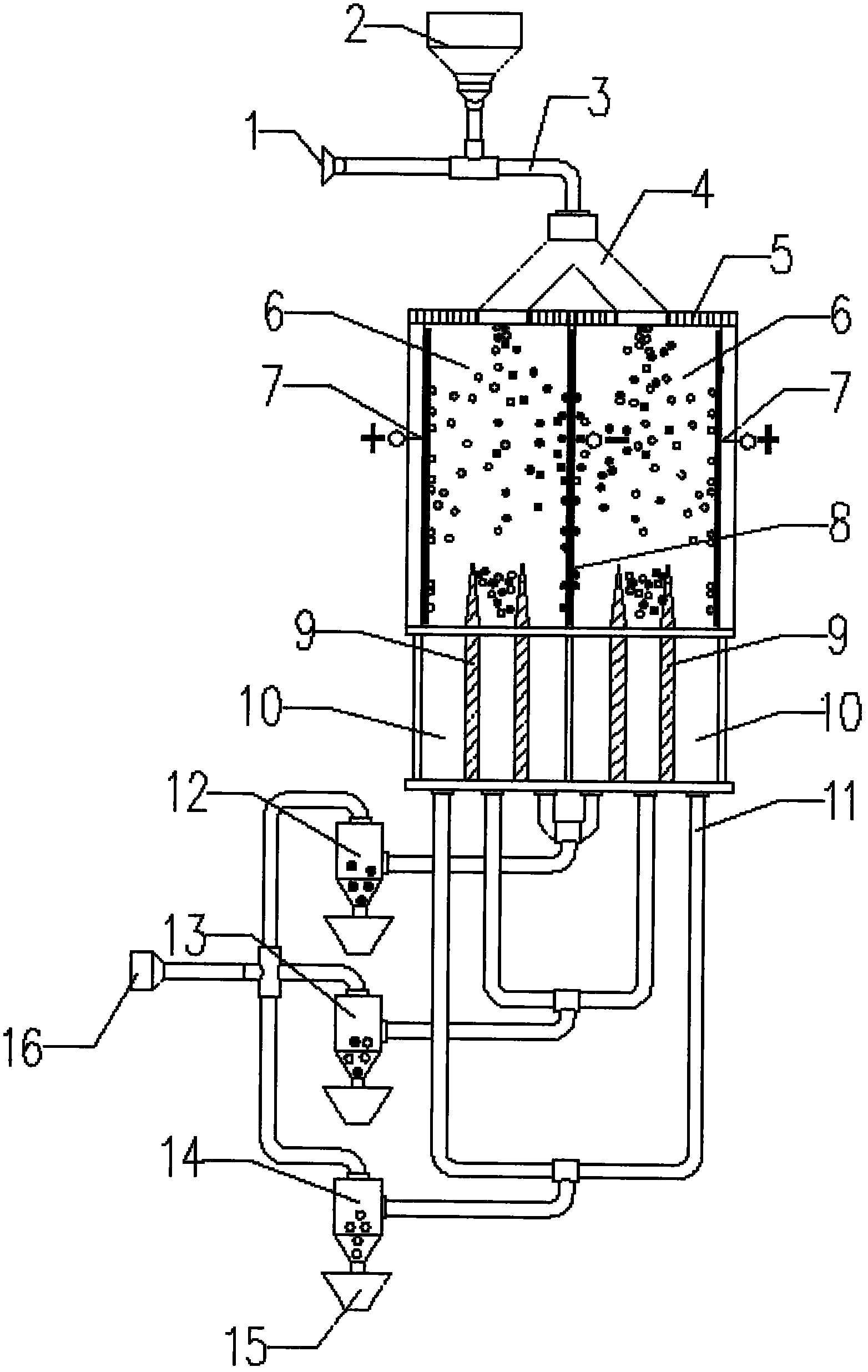

[0030] Example 1: A device for preparing cement water reducing agent by physical method, including high-pressure airflow inlet 1, fly ash feeding hopper 2, friction charging pipeline 3, material distribution pipe 4, air inlet 5, high-voltage electrostatic separation Cavity 6, positive high-voltage electrode plate 7, negative high-voltage electrode plate 8, ore separation plate 9, product collection chamber 10, material collection pipe 11, coal particle cyclone 12, medium ore cyclone 13, cement superplasticizer cyclone Device 14, collection hopper 15, vacuum negative pressure chamber 16. The fly ash feeding hopper 2 is fixedly connected perpendicular to the friction charging pipeline 3, one end of the friction charging pipeline 3 is fixedly connected to the high-pressure airflow inlet 1, and the other end is fixedly connected to the distribution pipe 4, and the distribution pipe 4 is installed in a The geometric center line of the air inlet 5 communicates with the left and righ...

Embodiment 2

[0034] Embodiment 2: A device for preparing cement water-reducer by physical method, the composition structure is the same as that of Embodiment 1.

[0035] The length L of the triboelectrically charged pipeline 3 1 =3m; diameter D=5cm; thickness h 1 =3mm; made of aluminum.

[0036] The pole distance between the positive and negative plates of the high-voltage electrostatic separation chamber 6 is 20cm; the thickness of the electrode plates is h 2 =3mm; the length L of a single high-voltage electrostatic separation chamber 6 2 =60cm; width B=30cm; applied voltage U=30kv.

[0037] The laboratory temperature is 25° C. and the relative humidity RH=23.5%. The loss on ignition of the de-coal ash obtained was 2.15%, and the yield was 60.20%; the loss on ignition of coal particles was 27.45%, and the yield was 14.88%.

[0038] It can be seen from Examples 1 and 2 that with the increase of the compound electric field voltage, the separation effect of the compound friction electri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com