High temperature and salt resistant polymer fluid loss additive for drilling fluid and preparation method of high temperature and salt resistant polymer fluid loss additive

A technology of fluid loss control agent and high temperature resistance, which is applied in the direction of drilling compositions, chemical instruments and methods, etc. It can solve the problems of uncommon fluid loss control agents, achieve ideal high temperature and salt resistance performance, and good fluid loss control Effect, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Synthesis of fluid loss control agent TSC-1:

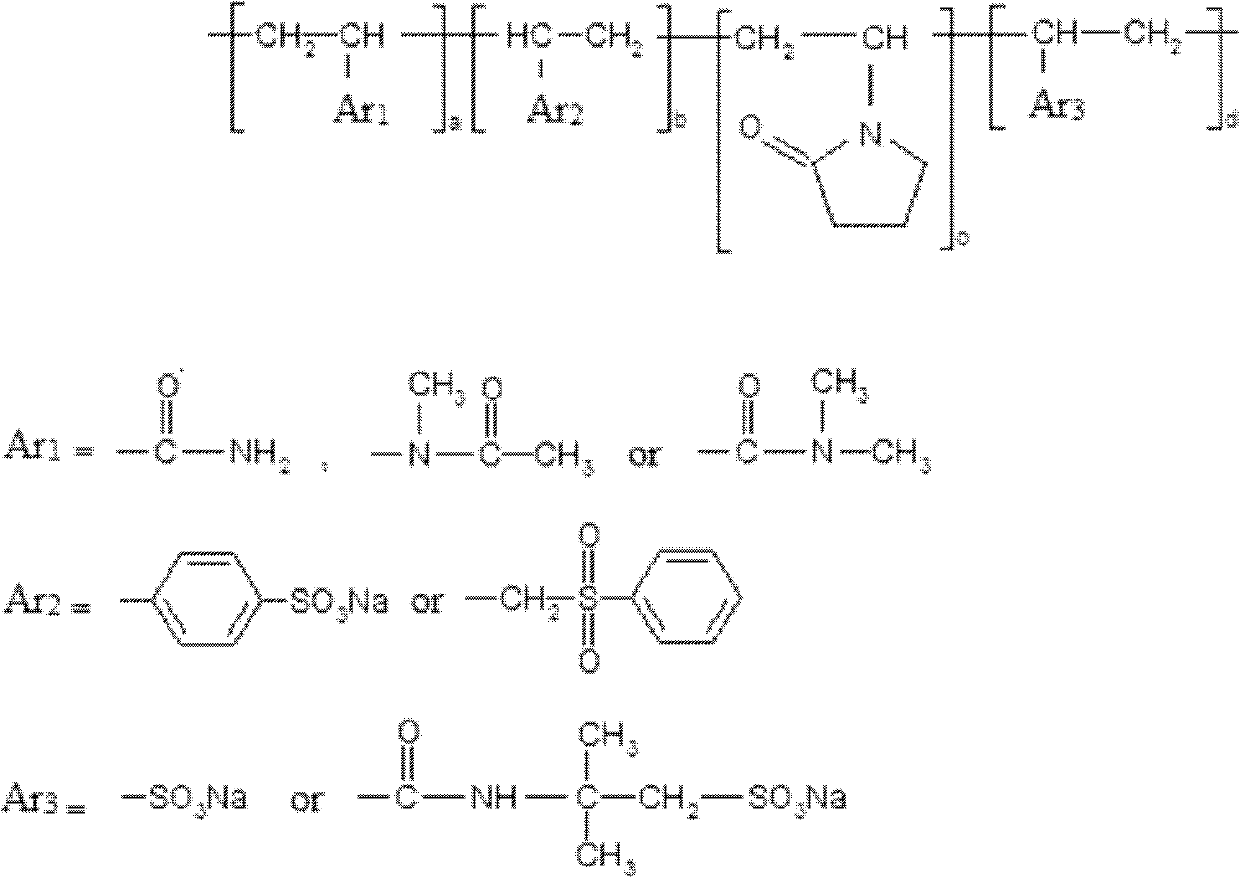

[0024] 20.7 g of 2-acrylamide-2 methylpropanesulfonic acid (AMPS) was dissolved in deionized water, and the solution was neutralized to pH=7-8 with about 4 g of NaOH. Mix 21.3g of acrylamide (AM), 8.3g of N-vinylpyrrolidone (NVP), 5.2g of sodium p-styrene sulfonate (SSS) with the neutralized AMPS solution, and add it to a four-necked flask with a thermometer and a reflux device Medium, stirring, passing nitrogen and deoxygenating. The reaction temperature was set at 45°C. After passing nitrogen for 30 minutes, 0.2% initiator was added, and the total monomer concentration was 20%. After reacting for 8 hours, the jelly was dried and pulverized to obtain the product TSC-1 with a yield of 91.7%. Its reaction formula is as follows:

[0025]

Embodiment 2

[0026] Example 2 Synthesis of fluid loss reducer TSC-2:

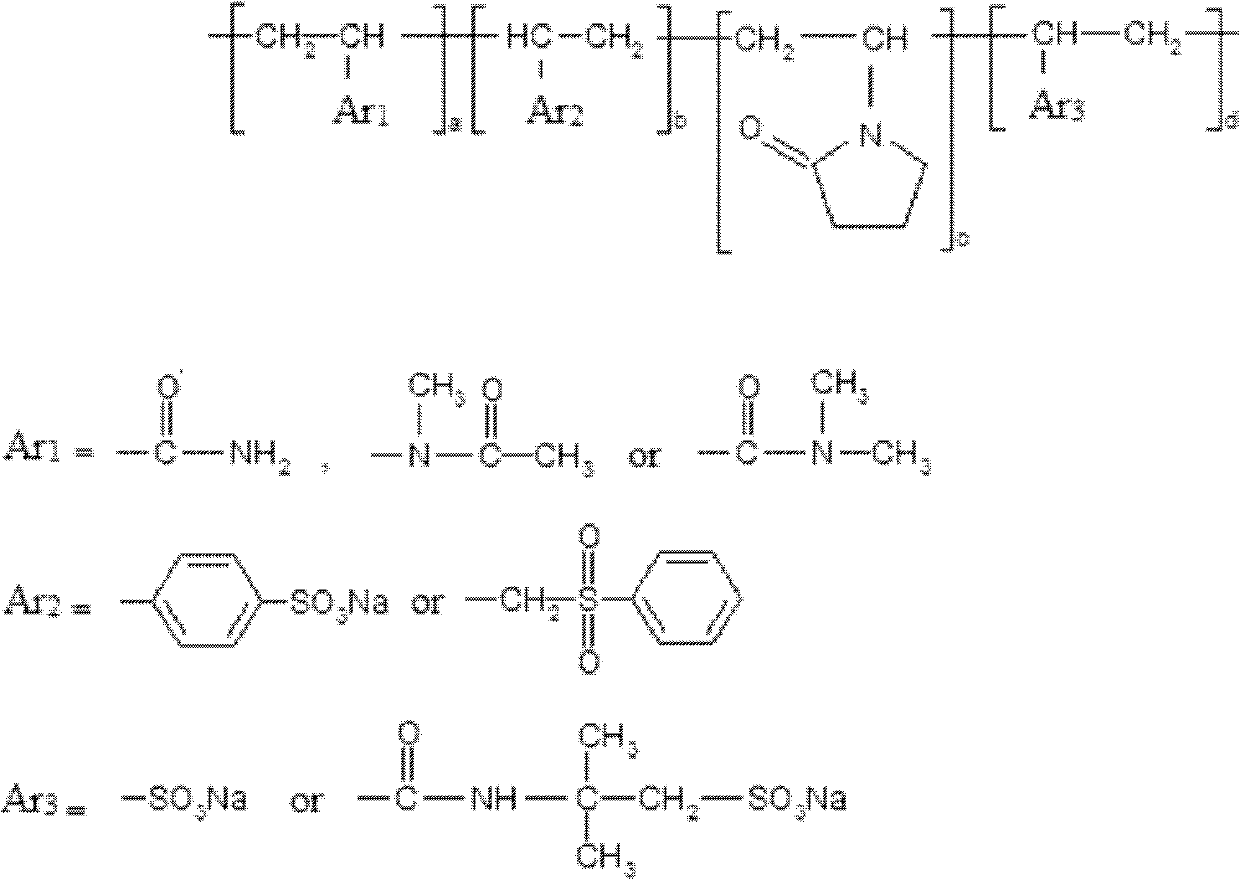

[0027] 20.7 g of 2-acrylamide-2 methylpropanesulfonic acid (AMPS) was dissolved in deionized water, and the solution was neutralized to pH=7-8 with about 4 g of NaOH. Mix 24.8g of N-vinyl-N-methylacetamide (VMA), 8.3g of N-vinylpyrrolidone (NVP), 15.5g of sodium vinylbenzene sulfonate (SSS) with the neutralized AMPS solution, add In a four-necked flask equipped with a thermometer and a reflux device, stir, pass nitrogen and exhaust oxygen. The reaction temperature was set at 60°C. After passing nitrogen for 30 minutes, 0.3% initiator was added, and the total monomer concentration was 20%. After reacting for 10 hours, the jelly was dried and pulverized to obtain the product TSC-2 with a yield of 90.1%. Its reaction formula is as follows:

[0028]

[0029] 2. Structural characterization of fluid loss control agent TSC

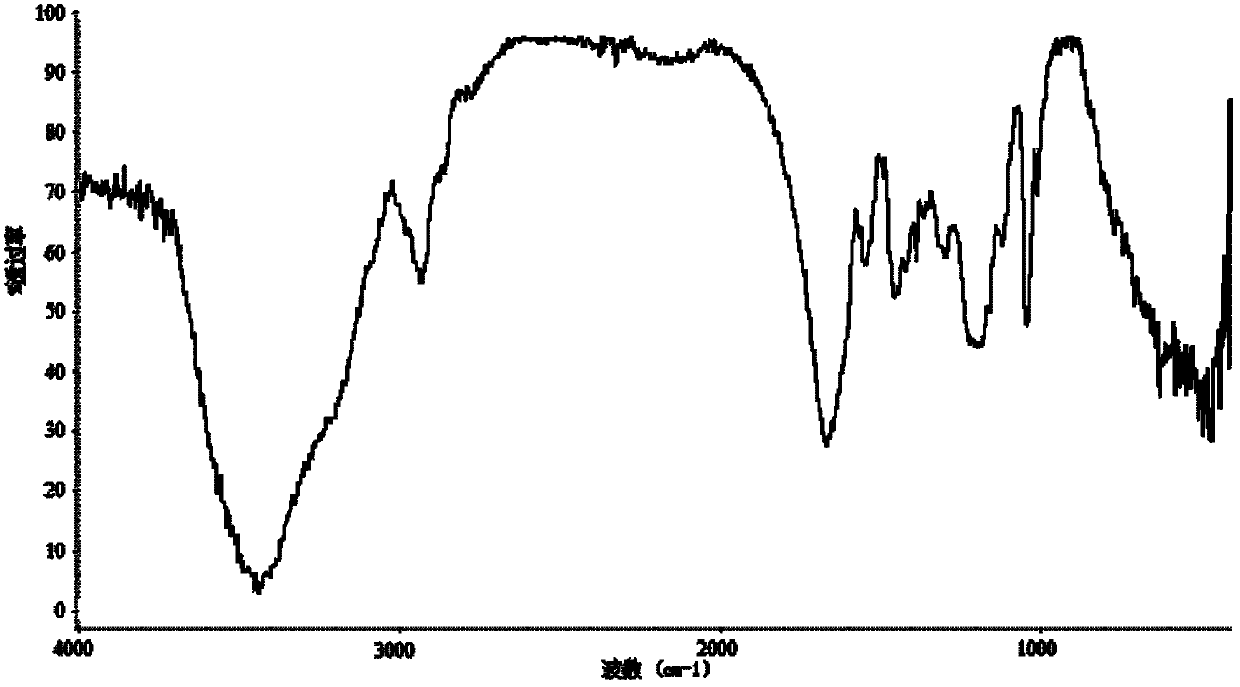

[0030] see figure 1 , figure 1 It is the infrared spectrogram of TSC-1, and the characteristic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com