Device for accelerating nanocrystallization of impact surfaces of metal round spheres by beating

A nano-sized and spherical technology, which is applied in the direction of explosive generating devices, metal processing equipment, manufacturing tools, etc., can solve the problems of complex equipment structure, long process time, small processing area, etc., and achieve high processing efficiency, simple configuration, and structure clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

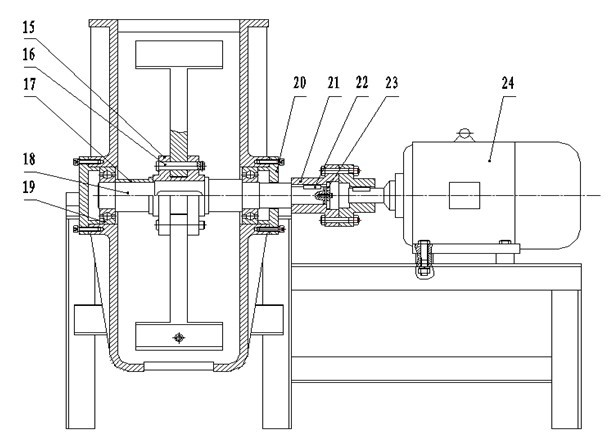

[0029] Such as Figure 2-5 As shown, the striking plate 12 is welded on the gasket 13, and the striking plate 12 and the gasket 13 are integrally fixed on the top of the rotating blade 11. The striking plate 12 must be made of high-quality materials with high strength and good hardness due to the collision acceleration of the ball. This improves the economic cost of the parts to a certain extent, and at the same time, the collision process will also cause stress loss such as pits and cracks on the surface of the striking plate 12, resulting in the failure of the striking plate 12. Therefore, in order to maintain the sustainability of the device In this design, the striking plate 12 is welded on the gasket 13, and fixed with the top of the rotating blade 11 with the bolt 14, so that on the one hand, the striking plate 12 can be supported to realize the impact guarantee, and the material used for the components is reduced. cost and resource saving; on the other hand, when the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com