Dyeing method of aromatic polyamide fiber

A technology of aromatic polyamide and polyamide fiber, which is applied in the direction of dyeing method, fiber type, fiber treatment, etc., can solve the problems of difficult dyeing, achieve improved dyeing fastness, good deep dyeing, and increase K/S value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Pretreatment: Treat the aramid fiber in a treatment solution of 10g / L sodium hydroxide and a liquor ratio of 1:50 at 100°C for 30 minutes, and then wash it with water.

[0021] 2. Dyeing: dye the pretreated aromatic polyamide fibers with cationic dyes, the dyeing process prescription is: carrier CINDYE DNK dosage 15%owf, dye MAXILON Blue SL dosage 5%owf, sodium nitrate dosage 10g / L, pH= 3. The bath ratio is 1:30. (2) Dyeing process conditions: add carrier, sodium nitrate and dye at room temperature, adjust the pH value with formic acid, raise the temperature to 135°C at 1°C / min, keep it warm for 60 minutes, then cool down to 70°C at 1°C / min, drain the bath , washed with water. Then measure the K / S value and color fastness of the dyed fiber.

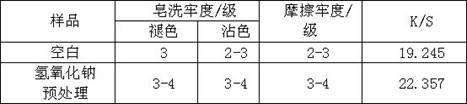

[0022] The test results of fibers treated with sodium hydroxide were compared with those of fibers not treated with sodium hydroxide, as shown in Table 1.

[0023] Table 1. Comparison of K / S value and color fastness of fibers...

Embodiment 2

[0027] Example 2: Effect of carrier CINDYE DNK dosage on K / S value.

[0028] In the dye liquor with a dyestuff MAXILON Blue SL concentration of 5% owf, an amount of sodium nitrate of 10g / L, pH=3, a bath ratio of 1:30, and a carrier CINDYE DNK amount of 0-20% owf, other process conditions are as in Example 1, for The aramid fibers pretreated with sodium hydroxide were dyed respectively, and then the K / S value of the dyed samples was measured, and the statistical results are shown in Table 2.

[0029] Table 2. Effect of carrier CINDYE DNK dosage on K / S value.

[0030] Carrier CINDYE DNK dosage / %owf K / S value 0 19.147 5 20.724 10 21.431 15 22.357 20 22.518

[0031] .

[0032] It can be seen from Table 2 that the K / S value of the dyed sample increases significantly after the carrier is added to the dyeing bath. This is because: the carrier plasticizes the fiber, increases the mobility of the fiber macromolecular chain, and relaxes the fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com