SCR (selective catalyst reduction) jetting system

An injection system and nozzle technology, which is applied in mufflers, engine components, machines/engines, etc., can solve the problems of adding blue crystals to block the injection holes, and achieve the effect of reducing the cost of the whole vehicle, simplifying the structure and simple control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

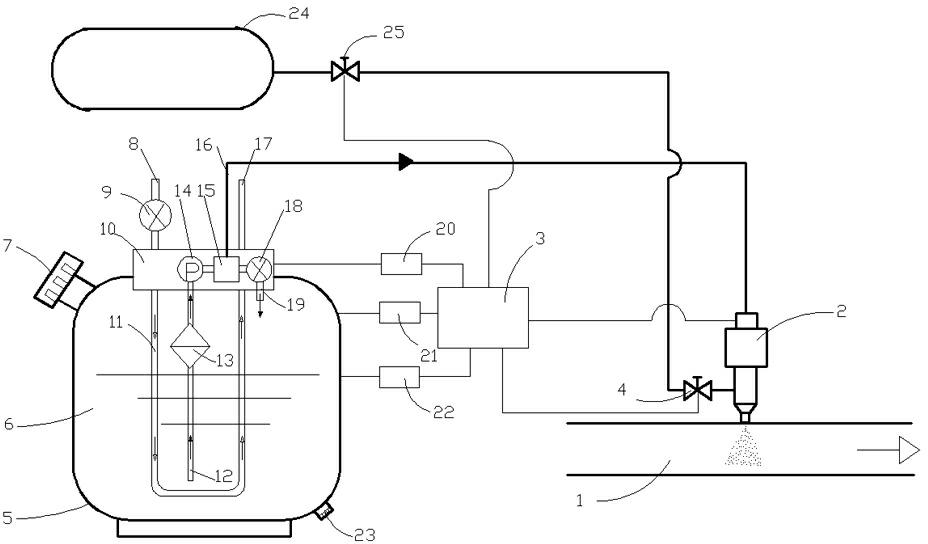

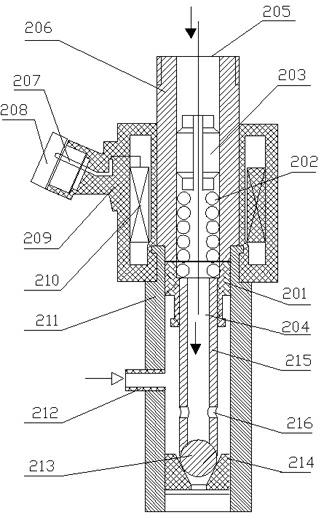

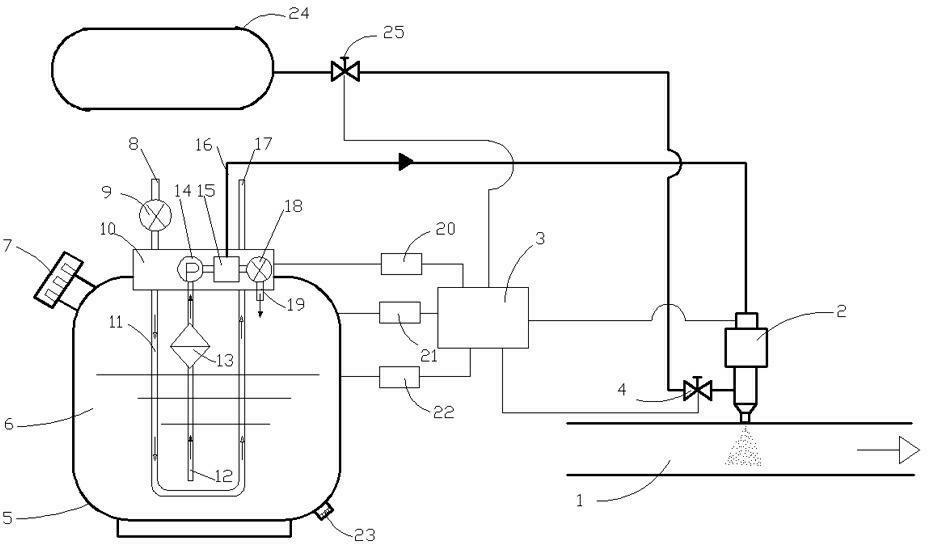

[0031] Such as figure 1 As shown, the SCR injection system of the present invention includes a blue tank, a delivery pump 24, a pressure accumulator chamber 15, a pressure regulating valve 18, an air storage tank 24, a nozzle 2, and an electronic control unit 3; Blue inlet; the output end of the pressure storage chamber 15 communicates with the blue inlet of the nozzle, and the output end of the air storage tank 24 communicates with the compressed air inlet of the nozzle. The pressure of the compressed air stored in the air storage tank 24 is 0.8-0.9 MPa, which is reduced to 0.4 MPa through the pressure reducing valve 25 , and the compressed air is connected to the nozzle 2 through the air solenoid valve 4 .

[0032] Tianlan tank includes a tank body 5, the top of the tank body 5 is provided with a pump body 10, and the pump body 10 is provided with a delivery pump 14, a pressure storage chamber 15 and a pressure regulating valve 18; the output end of the delivery pump 14 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com