Crankshaft radial two-way variable displacement piston pump

A two-way variable, radial column technology, applied in the direction of pumps, multi-cylinder pumps, liquid variable displacement machinery, etc., can solve the problems of low drive efficiency of the system, reduced equipment productivity, and can only be used for a single single action, so as to reduce Maintenance time and cost, increase productivity and capacity, and increase the effect of strategic reserve capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

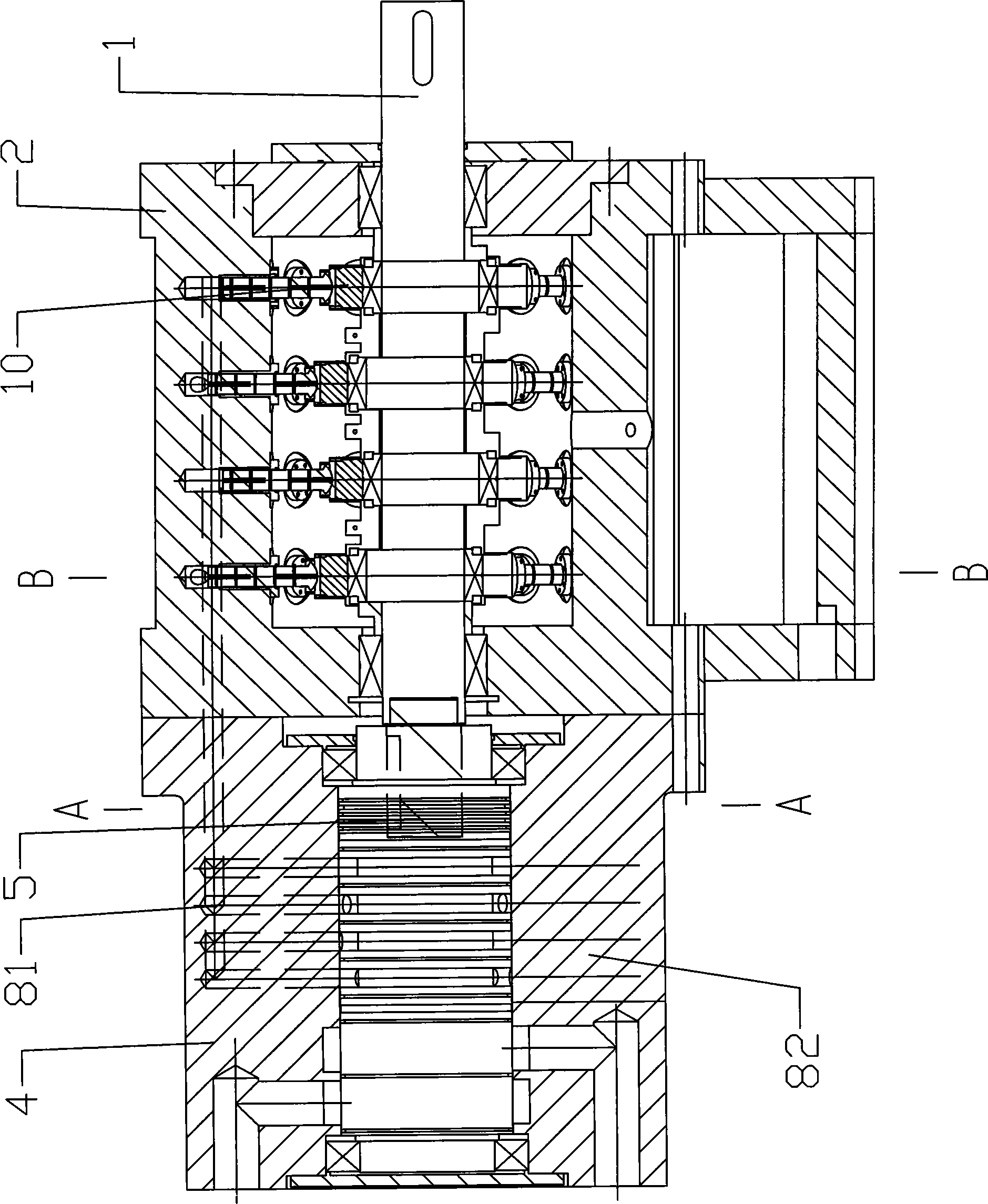

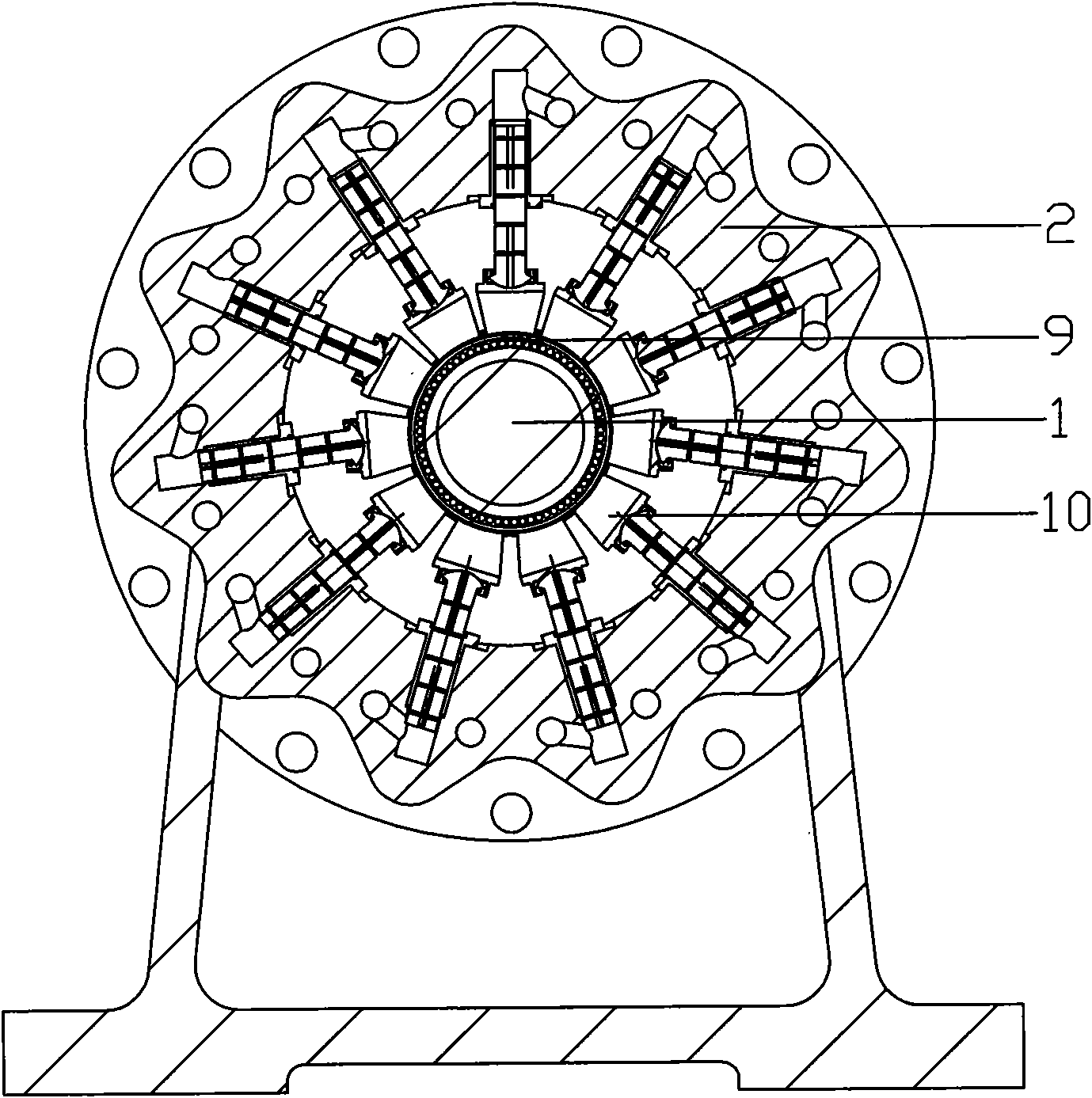

[0024] Such as Figure 1-3 As shown, a radial piston pump, the pump shaft 1 of the radial piston pump is installed on the pump body 2 through bearings; and the pump shaft 1 extends out of the radial column from the bottom end of the radial piston pump The pump body 2 of the plug pump is connected with the driving shaft of a coupling as the driving shaft of the coupling; the section of the driven shaft 3 of the coupling is circular, and there is also a extension block;

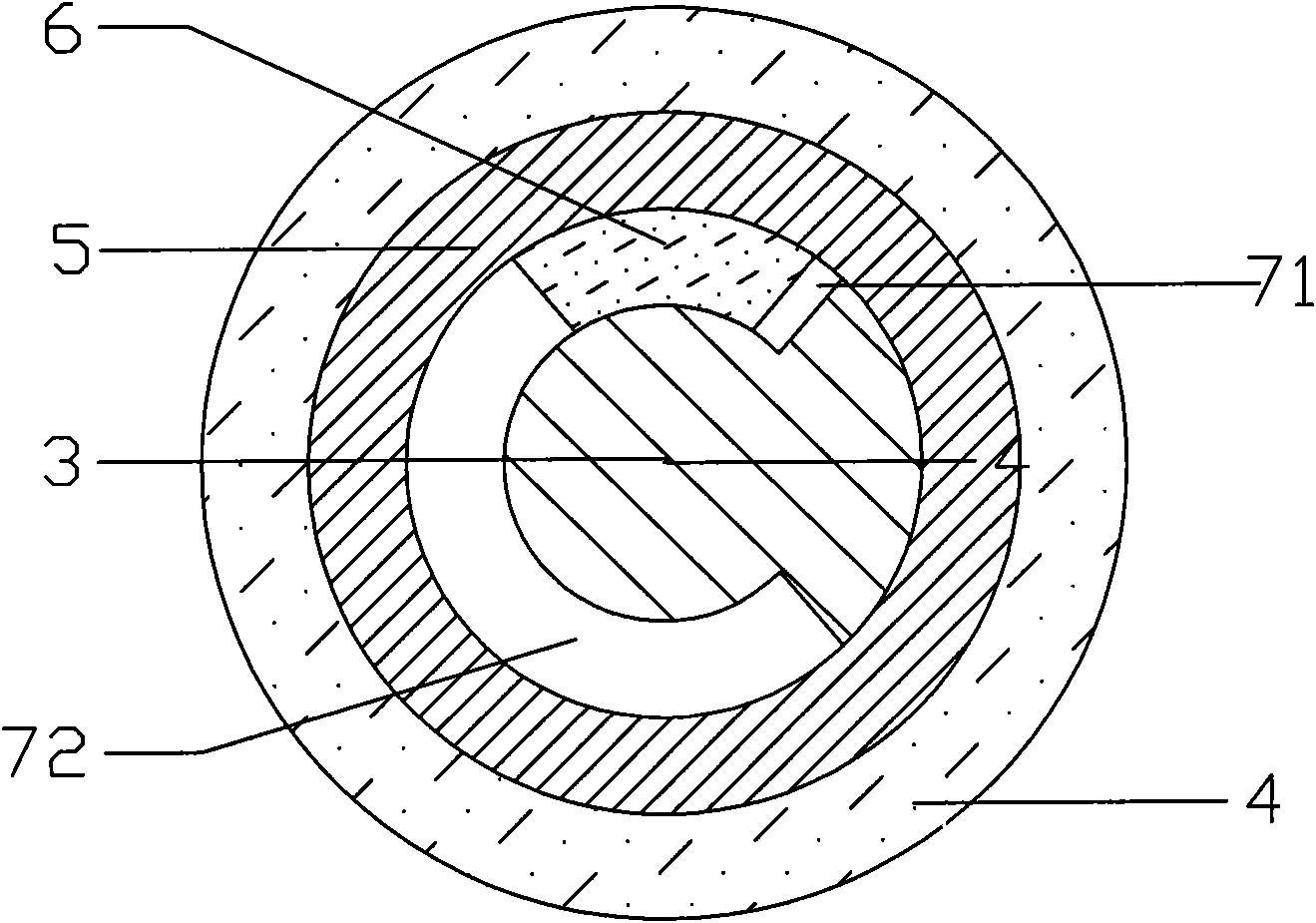

[0025] A flow divider is also provided, and the flow divider includes a housing 4, an oil distribution shaft 5 and a fixed block 6. The oil distribution shaft 5 is installed in the housing 4 through a bearing, and the bearing can be installed in the housing 4. 4 internal rotation; and the oil distribution shaft 5 is provided with a cavity, the section of the cavity is circular, and the section radius of the cavity is the same as the section radius of the driven shaft 3 of the coupling and the extension The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com