Ultrasonic wave detection device for thinning rate of body in white

A testing equipment, ultrasonic technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, using sonic/ultrasonic/infrasonic waves to analyze solids, measuring devices, etc., can solve problems affecting road test, strength and fatigue durability discount, and affecting vehicle quality , to reduce the probability of damage, improve detection efficiency, improve certainty and test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is attached figure 1 The present invention is further described.

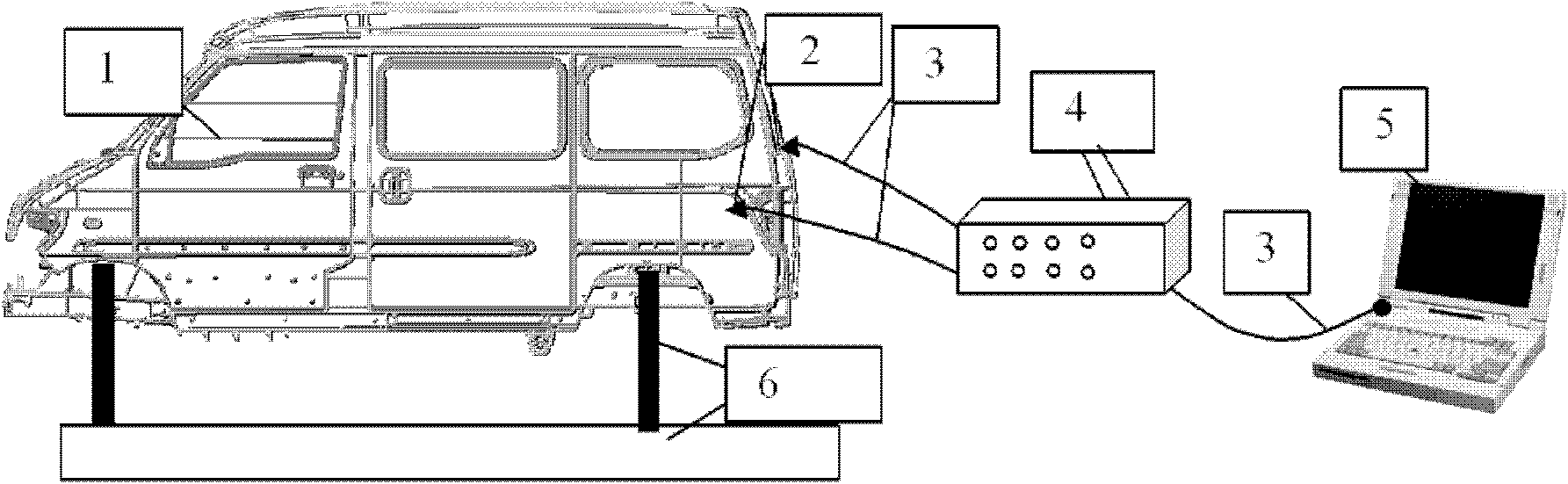

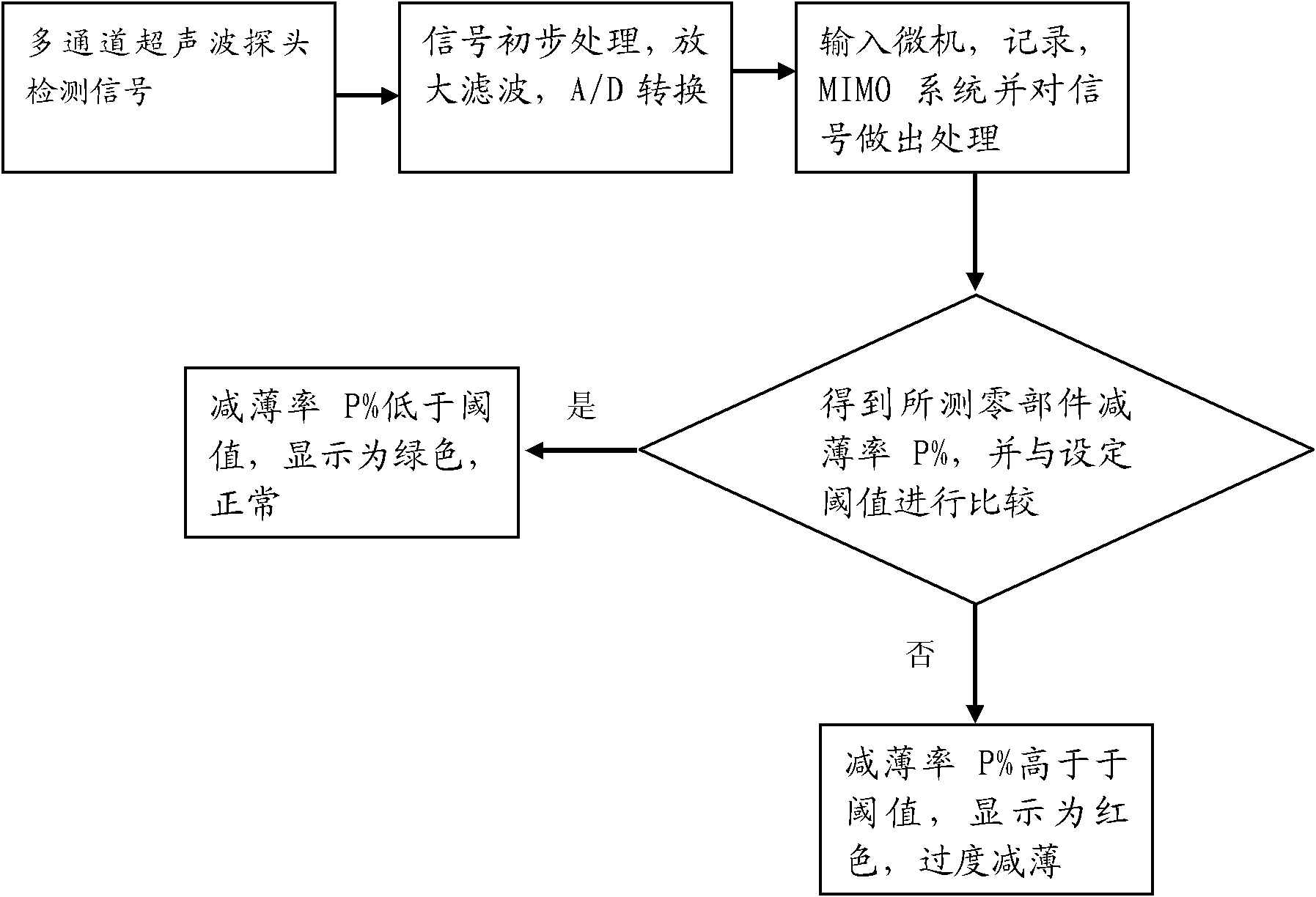

[0019] Such as figure 1 As shown, the ultrasonic testing equipment for body-in-white thinning rate of the present invention has hardware including an ultrasonic probe, a data acquisition and management system, a microcomputer, connecting cables, and a fixture system corresponding to the body-in-white; the software includes an analysis system. The specific installation method is as follows: the body in white is fixed on the stand by clamps, the ultrasonic probe is connected with the data acquisition and management system, the data acquisition and management system is connected with the computer, and the ultrasonic probe is attached to the key parts of the body.

[0020] Among them, (1) is the body-in-white detected by the testing equipment, which is a welding assembly. It is positioned by (6) bench and fixture system. The positioning points are the front wheel suspension support point and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com