Nitride distributed Bragg reflector (DBR) and manufacturing method and application thereof

A Bragg mirror, distributed technology, applied in the field of optoelectronics, can solve the problems of poor crystal quality, insufficient smooth interface, cracking of epitaxial layer, etc., to achieve improved luminous efficiency, high crystal quality and interface smoothness, and growth rate is easy to adjust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

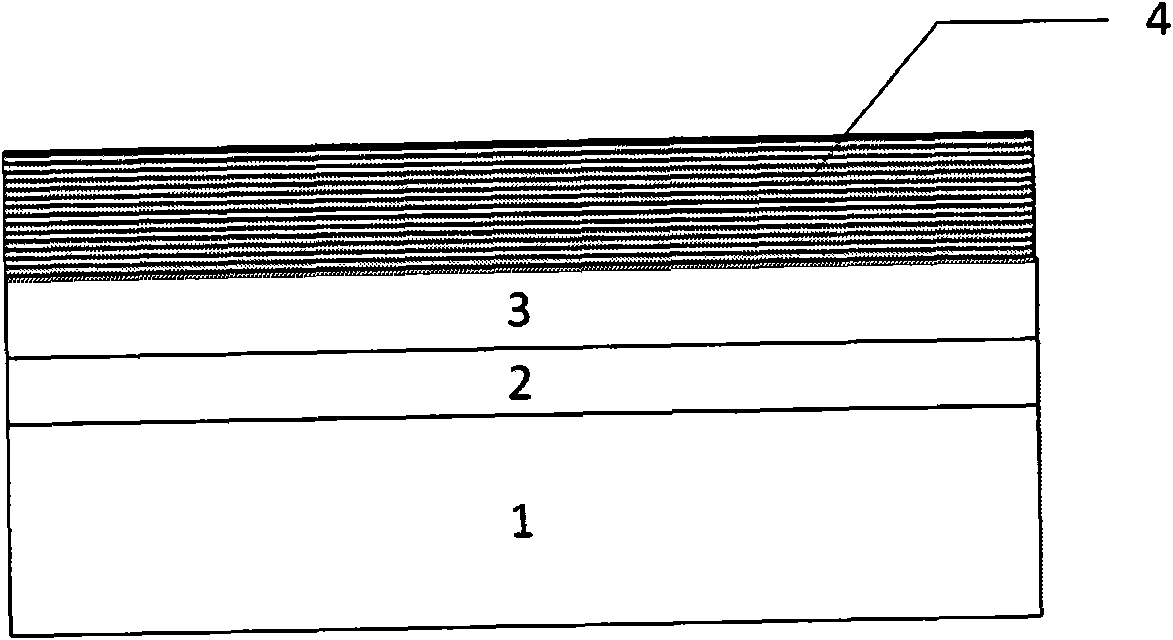

[0037] refer to figure 1 , to prepare Al on SiC substrates by metal-organic chemical vapor deposition x In y Ga 1-x-y N / Al u In v Ga 1-u-v Take the N-structure DBR as an example, including the following steps:

[0038] (1) The silicon carbide substrate 1 is placed in a reaction chamber of a metal organic chemical vapor deposition (MOCVD) furnace, heated to 1050° C. under a hydrogen atmosphere, and processed for 15 minutes.

[0039] (2) An aluminum nitride nucleation layer 2 is grown on a silicon carbide substrate 1 at a growth temperature of 1000° C., a thickness of 150 nm, and a growth pressure of 50 mbar.

[0040] (3) A non-doped gallium nitride layer (buffer layer) 3 is grown on the aluminum nitride nucleation layer 2 at a growth temperature of 1100° C., a growth thickness of 2 μm, and a growth rate of 2 μm / h.

[0041] (4) Al growth on the non-doped gallium nitride buffer layer 3 x In y Ga 1-x-y N / Al u In v Ga 1-u-v A distributed Bragg reflector (DBR structure) 4...

Embodiment 2

[0043] refer to figure 1 , to prepare Al on sapphire substrates by metal-organic chemical vapor deposition x In y Ga 1-x-y N / Al u In v Ga 1-u-v Take the N-structure DBR as an example, including the following steps:

[0044] (1) The sapphire substrate 1 is placed in the reaction chamber of a metal organic chemical vapor deposition furnace (MOCVD), heated to 1000° C. under a hydrogen atmosphere, and processed for 12 minutes.

[0045] (2) An AlGaN nucleation layer 2 is grown on a sapphire substrate 1 at a growth temperature of 900° C., a thickness of 120 nm, and a growth pressure of 70 mbar.

[0046] (3) A non-doped GaN layer 3 (buffer layer) is grown on the AlGaN nucleation layer 2 at a growth temperature of 1100° C., a growth thickness of 2 μm, and a growth rate of 2 μm / h.

[0047] (4) Al growth on the non-doped gallium nitride buffer layer 3 x In y Ga 1-x-y N / Al u In v Ga 1-u-v A distributed Bragg reflector 4 (DBR) composed of N quaternary structures, where x=0.3,...

Embodiment 3

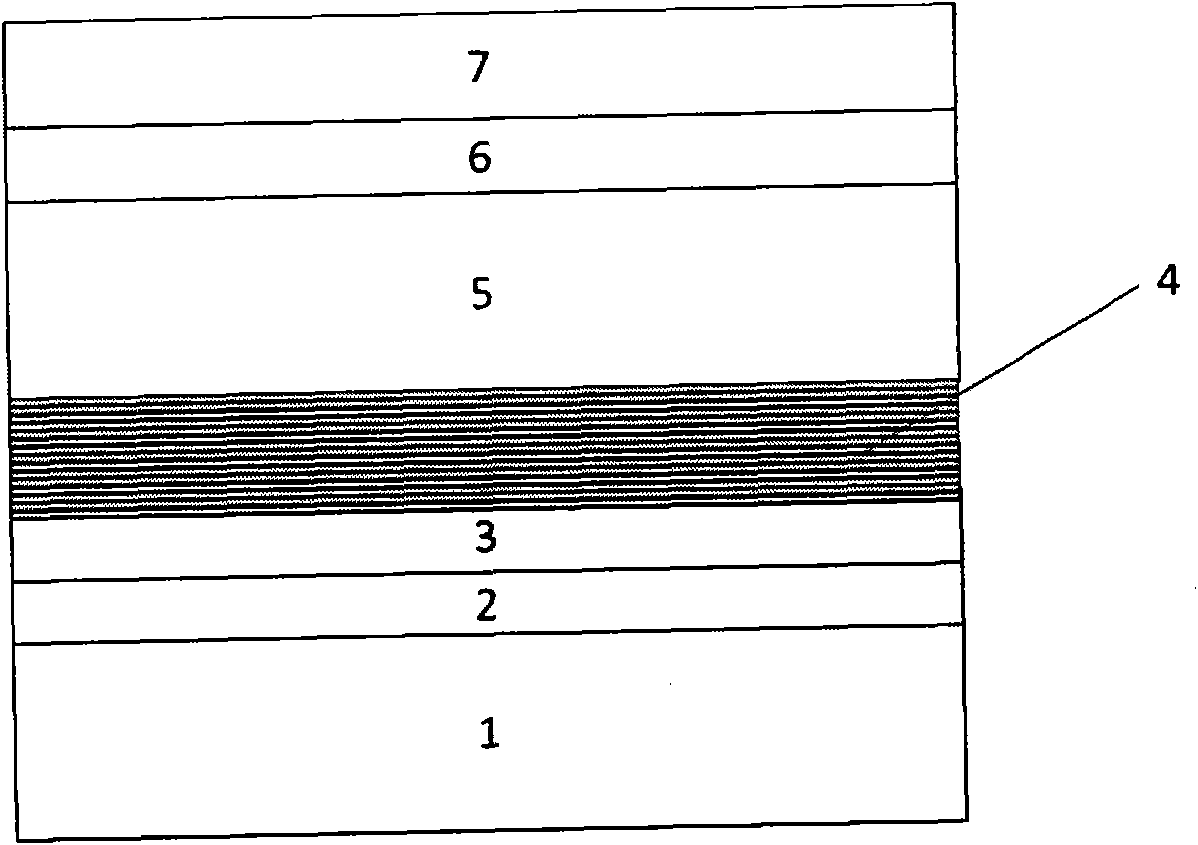

[0049] refer to figure 2 , taking the preparation of DBR-containing gallium nitride-based light-emitting diodes on a sapphire substrate as an example, the steps are as follows:

[0050] (1) The sapphire substrate 1 is placed in a reaction chamber of a metal organic chemical vapor deposition (MOCVD) furnace, heated to 1000° C. under a hydrogen atmosphere, and processed for 10 minutes.

[0051] (2) Growing gallium nitride nucleation layer 2 on sapphire substrate 1 . The growth temperature is 600° C., and the thickness is 50 nm. The growth pressure was 300 mbar.

[0052] (3) A non-doped gallium nitride layer 3 is grown on the gallium nitride nucleation layer 2 at a growth temperature of 1050° C., a growth thickness of 1.5 μm, and a growth rate of 3 μm / h. The growth rate was 3 μm / h.

[0053] (4) Al growth on GaN buffer layer 3 x In y Ga 1-x-y N / Al u In v Ga 1-u-v DBR 4 composed of N quaternary structures, where x=0.3, y=0.3, u=0.2, v=0.4. The number of repetitions is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com