Method for preparing tetragonal-phase room-temperature multi-ferroic material BiFeO3

A phase room temperature multiferroic, tetragonal technology, applied in the growth of polycrystalline materials, chemical instruments and methods, metal material coating technology and other directions, can solve the problem of unable to maintain the tetragonal phase structure, etc. Simple, great adjustment of the elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not used to limit the present invention.

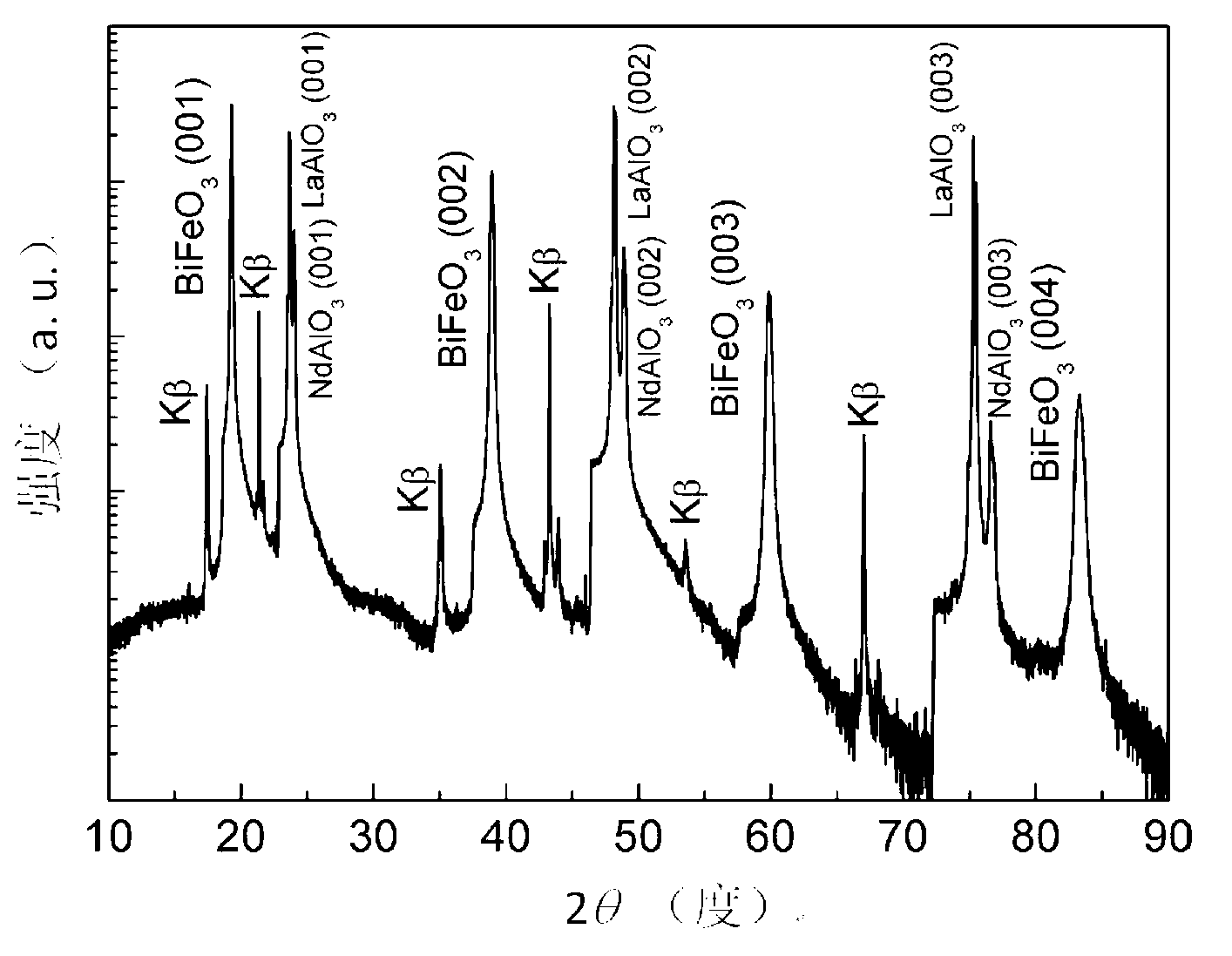

[0016] The purpose of the present invention is to provide a tetragonal phase room temperature multiferroic material BiFeO 3 The preparation process, the preparation method is first in (001) LaAlO 3 Prepare a layer of NdAlO on the substrate 3 Buffer layer in NdAlO 3 Deposit BiFeO on the buffer layer 3 The thin film can obtain single-phase tetragonal BiFeO with a larger thickness range 3 film.

[0017] In the embodiment of the present invention, various thin film preparation processes such as pulsed laser deposition technology, magnetron sputtering, and molecular beam epitaxy technology can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com