Homoepitaxial gallium nitride high electron mobility transistor based on p-type gan leakage isolation layer and manufacturing method

A technology with high electron mobility and gallium nitride, applied in the field of high electron mobility transistors, can solve the problem of reducing device breakdown voltage and output power density, increasing the difficulty of material growth process and parasitic pollution, affecting the output of device current and power, etc. Characteristics and other issues, to achieve the effect of improving breakdown voltage and working reliability, increasing process repeatability and consistency, and reducing high-ohm contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

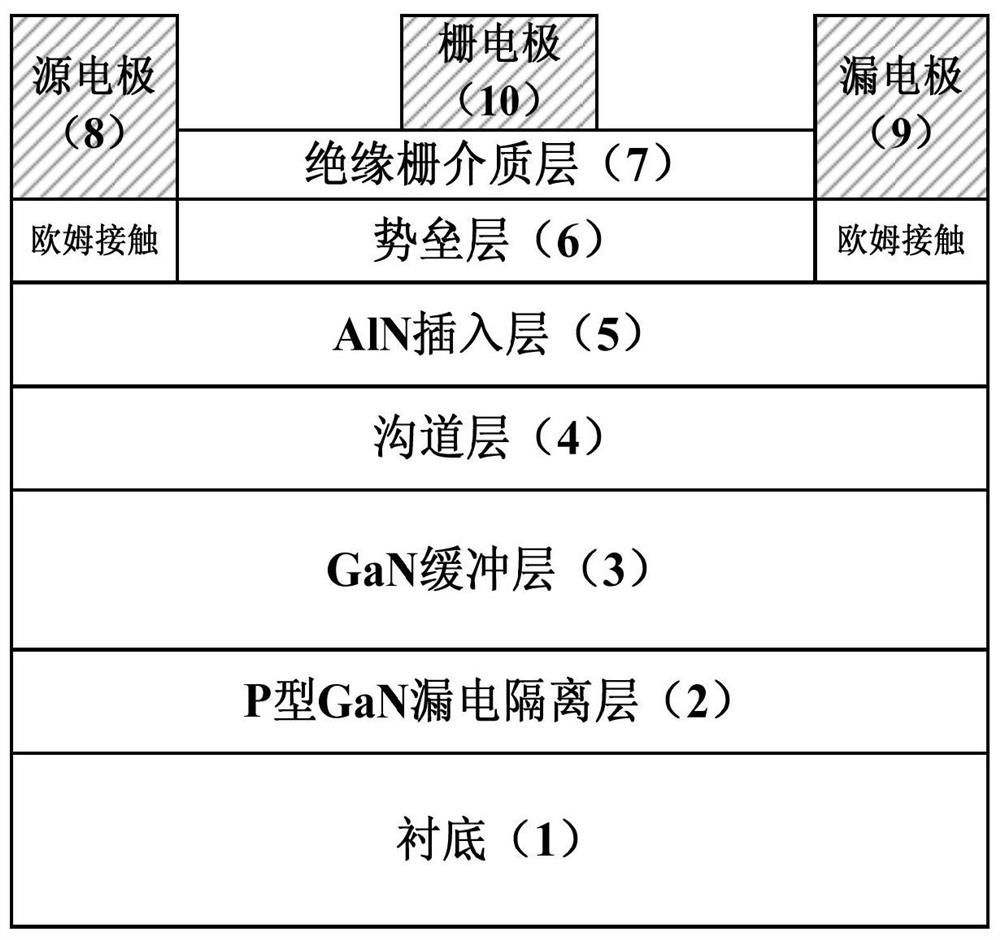

[0048]Embodiment 1, a homoepitaxial gallium nitride high electron mobility transistor with a self-supporting gallium nitride substrate, a GaN channel layer with a thickness of 20 nm, and an AlGaN barrier layer with a thickness of 30 nm is used as the fabrication substrate.

[0049] Step 1, depositing a P-type GaN leakage isolation layer, such as image 3 (a).

[0050] A self-supporting gallium nitride substrate is selected and placed in a reaction chamber, and a P-type GaN leakage isolation layer with a thickness of 500nm is deposited by metal-organic chemical vapor deposition technology.

[0051] The process conditions used to deposit the P-type GaN leakage isolation layer are: temperature 1100°C, pressure 40Torr, ammonia gas flow rate 2000 sccm, gallium source flow rate 100 sccm, magnesium source flow rate 20 sccm, nitrogen gas flow rate 3000 sccm.

[0052] Step 2, depositing a GaN buffer layer, such as image 3 (b).

[0053] A GaN buffer layer with a thickness of 10 μm i...

Embodiment 2

[0071] In the second embodiment, a homoepitaxial gallium nitride high electron mobility transistor with a thick-film gallium nitride substrate material, an InGaN channel layer with a thickness of 10 nm, and an InAlN barrier layer with a thickness of 12 nm is used as the fabrication substrate.

[0072] Step 1, depositing a P-type GaN leakage isolation layer on the thick-film gallium nitride substrate material, such as image 3 (a).

[0073] Select the thick-film GaN substrate material and place it in the reaction chamber, using metal organic chemical vapor deposition technology, at a temperature of 1050 ° C, a pressure of 40 Torr, an ammonia gas flow of 2000 sccm, a gallium source flow of 120 sccm, nitrogen A P-type GaN leakage isolation layer with a thickness of 100nm is deposited on the thick-film gallium nitride substrate material under the process conditions that the flow rate is 3000sccm and the flow rate of the magnesium source is 30sccm.

[0074] Step 2, depositing a Ga...

Embodiment 3

[0087] Embodiment 3, a homoepitaxial gallium nitride high electron mobility transistor with a self-supporting gallium nitride substrate, a GaN channel layer thickness of 50 nm, and a ScAlN barrier layer thickness of 5 nm is used as the fabrication substrate.

[0088] Step A, select a self-supporting gallium nitride substrate, and place it in a reaction chamber, using metal-organic chemical vapor deposition technology, at a temperature of 1150 ° C, a pressure of 40 Torr, an ammonia flow rate of 2000 sccm, and a gallium source flow rate of 90sccm, the flow rate of nitrogen gas is 3000sccm, and the flow rate of magnesium source is 10sccm, a P-type GaN leakage isolation layer with a thickness of 1000nm is deposited on the self-supporting gallium nitride substrate, as image 3 (a).

[0089]Step B, using metal-organic chemical vapor deposition technology, under the process conditions of temperature 1150°C, pressure 40 Torr, ammonia gas flow rate 2000 sccm, gallium source flow rate 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com