Method for producing resistive random access memory device capable of multilevel memory

A technology of resistive variable storage and multi-value storage, which is applied in the direction of electrical components, etc., to achieve the effect of continuous structure, strong process controllability, and stable and uniform film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

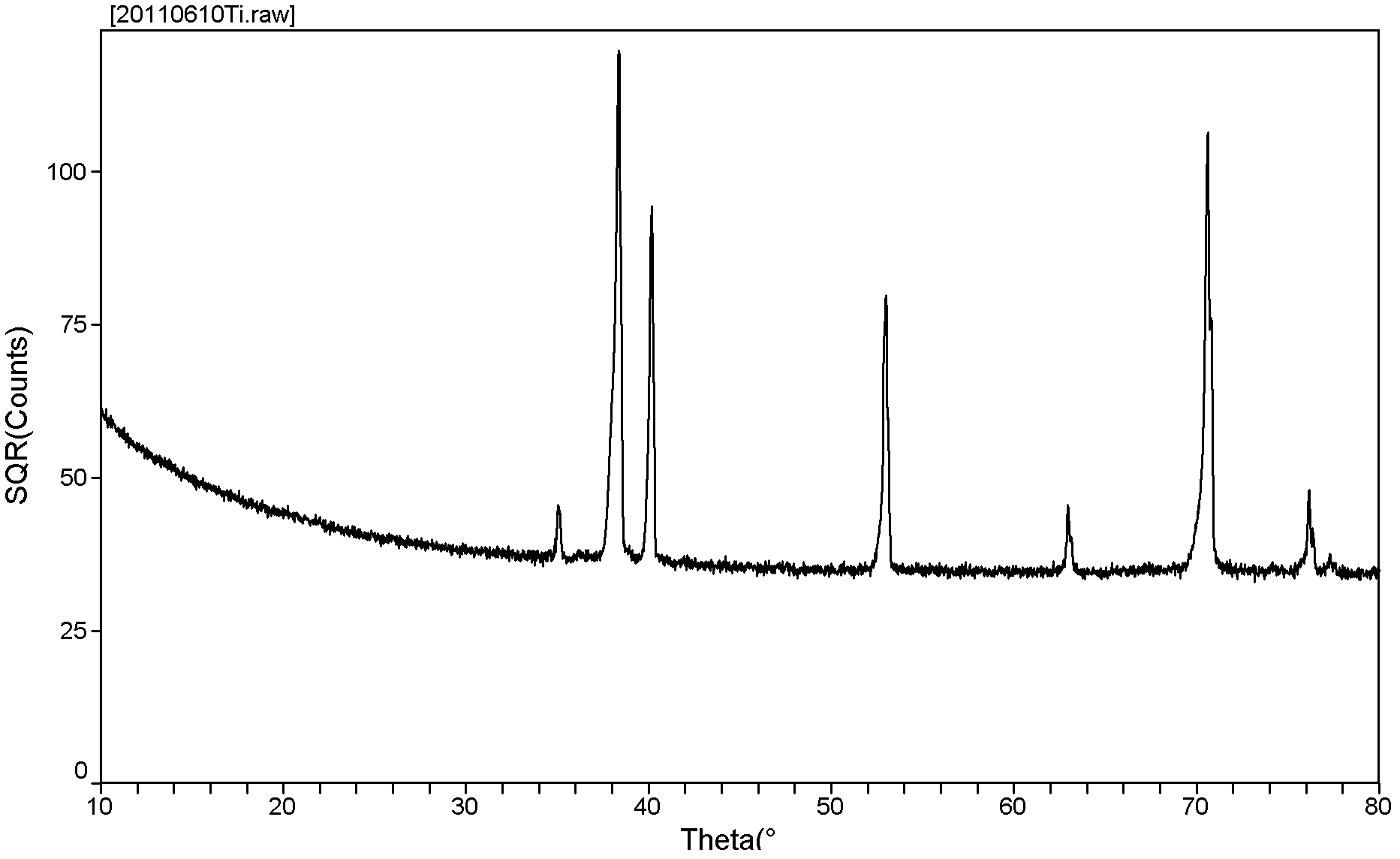

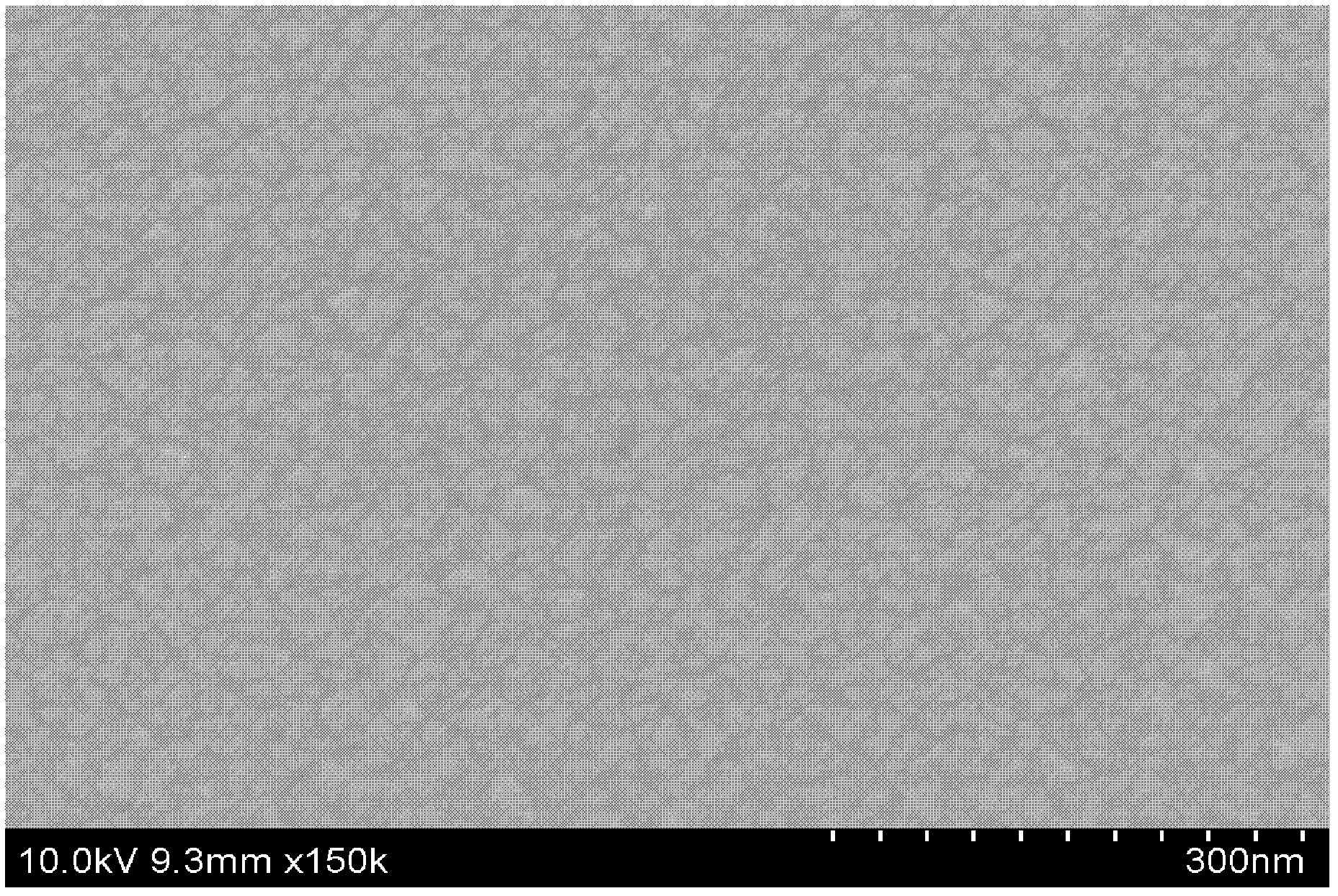

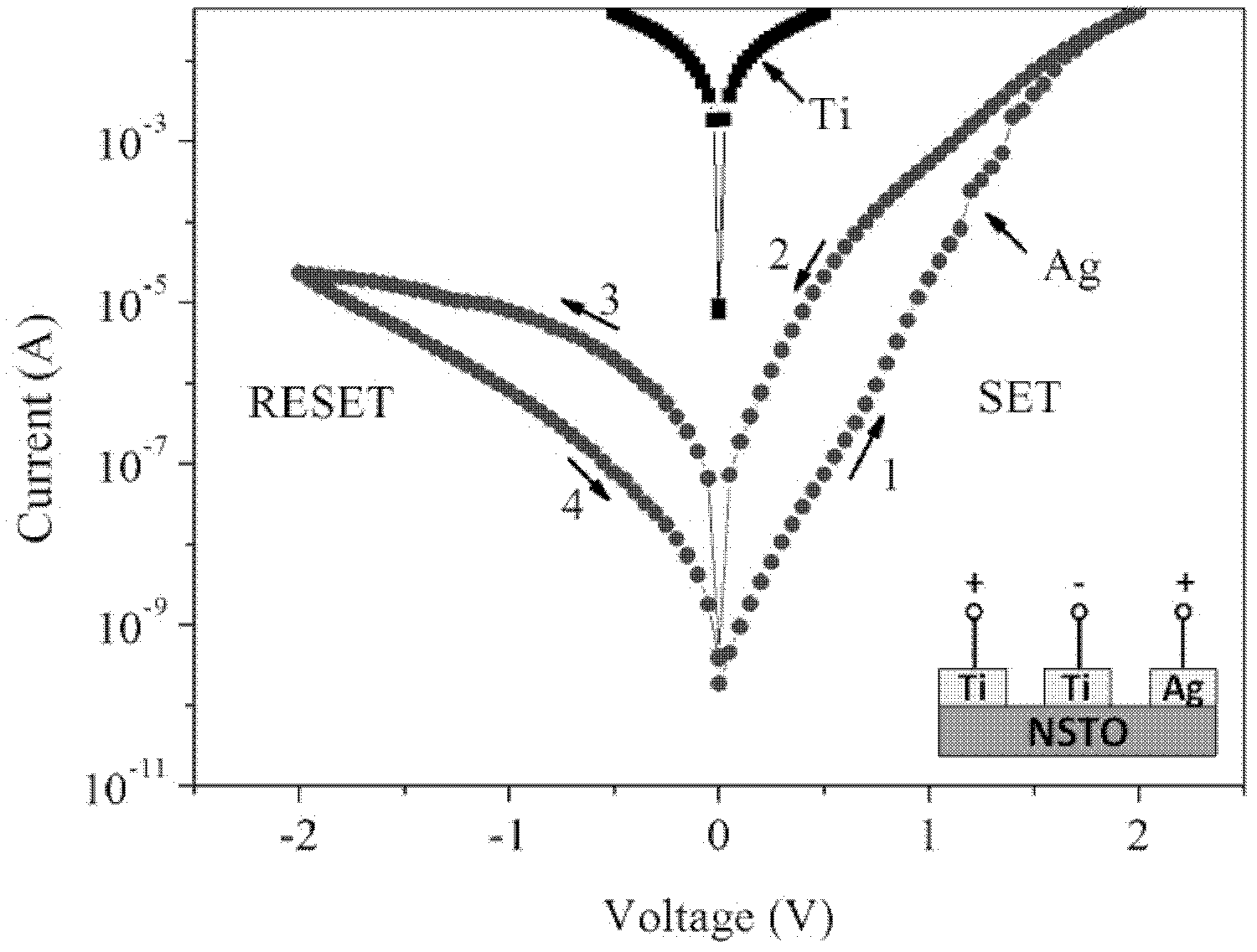

[0023] Take a piece of Nb:SrTiO with a size of 10mm×5mm×0.5mm 3 As the substrate, it was ultrasonically cleaned in deionized water, acetone, deionized water, ethanol, and deionized water, and dried naturally. The substrate was placed in a vacuum of 8 x 10 -4 pa, annealed at 700°C for 30 minutes and then cooled down to room temperature naturally. Then the middle part of the substrate is blocked with a mask, and the exposed Nb:SrTiO 3 A metal titanium (Ti) film with a thickness of 180nm was sputtered, and its X-ray diffraction (XRD) and scanning electron microscope (SEM) showed figure 1 , figure 2 . Then remove the mask plate, in Nb:SrTiO 3 Coated with metallic silver (Ag glue). Metal titanium (Ti) and titanium (Ti) are connected in series with metal copper wire (Cu) and metal titanium (Ti) and metal silver (Ag) are connected in series with metal copper wire (Cu), and metal silver (Ag) is used as For the positive electrode, test their I-V characteristics respectively for...

Embodiment 2

[0025] Take a piece of Nb:SrTiO with a size of 10mm×5mm×0.5mm 3 is the substrate, where Nb:SrTiO 3 SrTiO doped with 0.7% Nb 3 Single crystal substrates were ultrasonically cleaned in deionized water, acetone, deionized water, ethanol, and deionized water. The ultrasonic cleaning time was 5 min, 10 min, 5 min, 10 min, and 5 min, respectively; and then dried naturally. The substrate was placed in a vacuum of 8 x 10 -4 pa, annealed at 700°C for 30 minutes and then cooled down to room temperature naturally. Then cover one-third of the middle part of the substrate with a mask, and use the method of radio frequency magnetron sputtering on the exposed Nb:SrTiO 3 Sputter a layer of metal titanium (Ti) film with a thickness of 160nm, the sputtering power used is 250W, the sputtering pressure is 1.2pa, and the sputtering time is 1.5h; then the mask plate is removed, and the Nb:SrTiO 3 Coated with metallic silver (Ag glue). Metal titanium (Ti) and titanium (Ti) are connected in seri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com