Back coating composition and mirror

A technology of composition and coating, applied in the direction of mirrors, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as silver mirror film corrosion, and achieve excellent acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

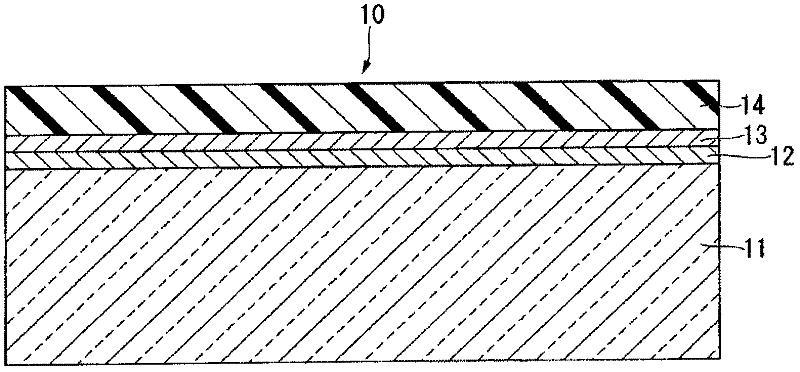

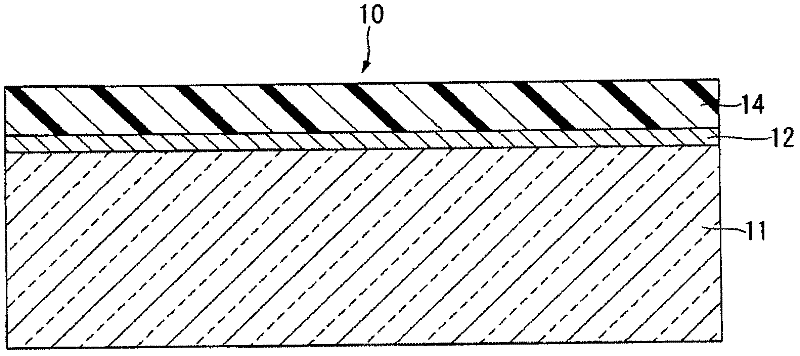

Image

Examples

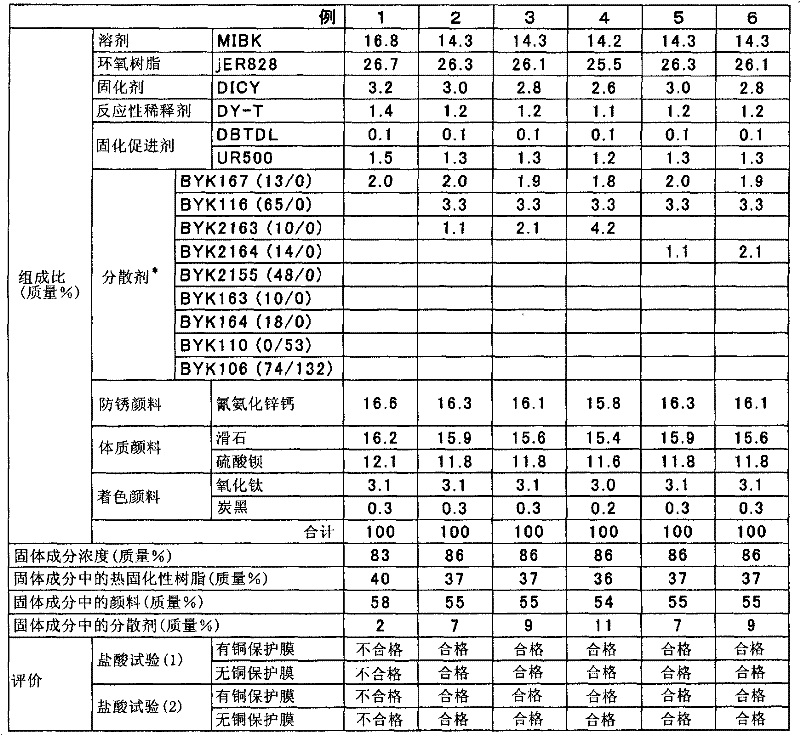

example 1

[0107] According to the composition ratio shown in the column of Example 1 of Table 1, each raw material was sealed in a paint shaker and shaken for 15 minutes to prepare a back coating composition.

[0108] Spray a silver plating solution made of a solution containing silver nitrate and a reducing solution that reduces silver on the surface of a fully cleaned glass substrate (size 90mm×40mm×5mm), and the silver is precipitated by the silver mirror reaction to form a film with a thickness of 1.0g / m 2 silver mirror mask.

[0109] After the surface of the silver mirror film is washed with water, a copper plating solution consisting of a solution containing copper sulfate and a reducing solution for reducing copper is sprayed on the surface, and copper is precipitated by an electroless plating method to form a film thickness of 0.3 / m 2 copper protective film.

[0110] After the surface of the copper protective film was washed with water and dried, the temperature of the glass...

example 2~16

[0116] Each raw material was prepared according to the composition ratio shown in the columns of Examples 2-16 of Tables 1-3, and the back coating composition which has the composition described in each column was prepared, respectively.

[0117] Except changing the back coating composition, the same operation as Example 1 was carried out to obtain mirrors (with copper protective film and without copper protective film).

example 17~32

[0119] Each raw material was prepared according to the composition ratio shown in the columns of Examples 17-32 of Tables 4-6, and the back coating composition which has the composition described in each column was prepared, respectively.

[0120] Except changing the back coating composition, the same operation as Example 1 was carried out to obtain mirrors (with copper protective film and without copper protective film).

[0121] Based on the evaluation results of the viscosity of the back coating compositions described in Examples 1 to 32, the following hydrochloric acid test (1) and the following hydrochloric acid test (2) were performed on mirrors obtained using the back coating compositions described in Examples 1 to 32. The results of the performance test and the results of evaluating the appearance of the coating film of the back coating composition are shown in Tables 1-6, respectively.

[0122] (hydrochloric acid test (1))

[0123] A mirror of size 90 mm x 40 mm was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com