Preparation method of hollow carbon nanocage loaded platinum-based composite catalysts

A composite catalyst and nanoparticle technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of difficult batch preparation, limited application, etc. Narrow diameter distribution, good dispersion, good catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

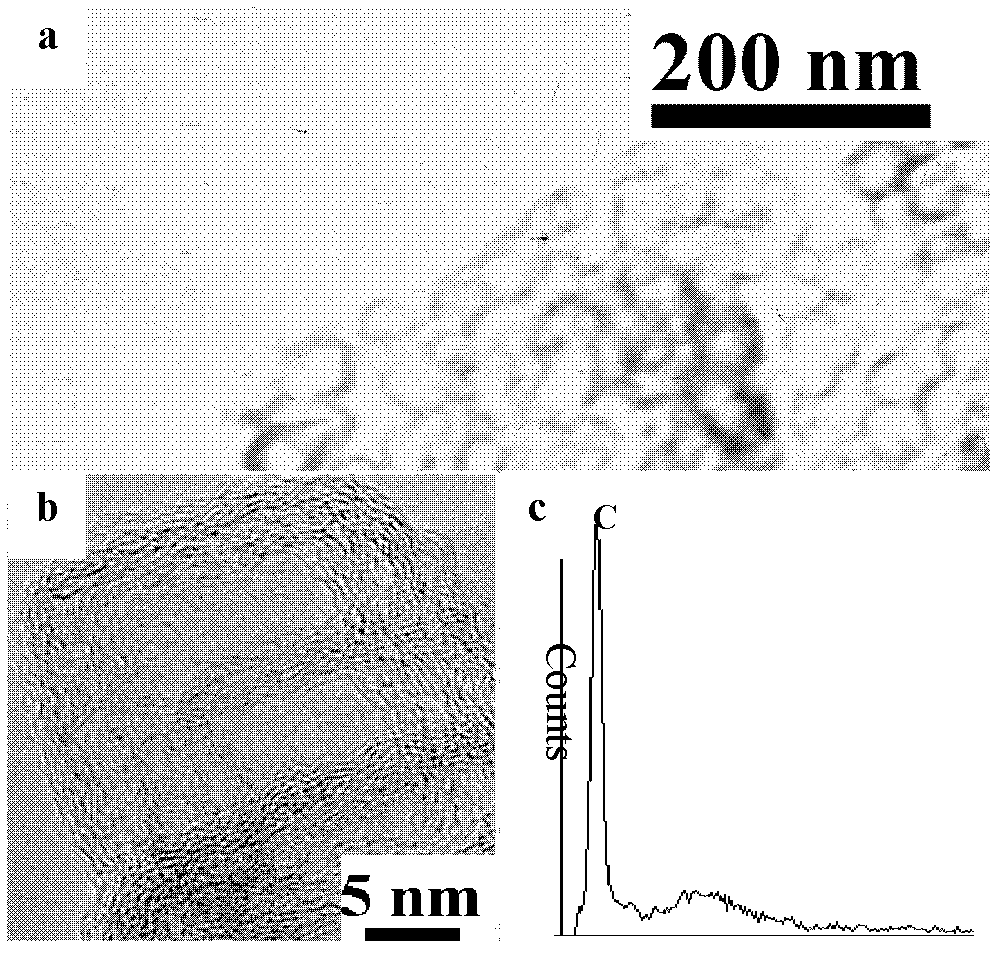

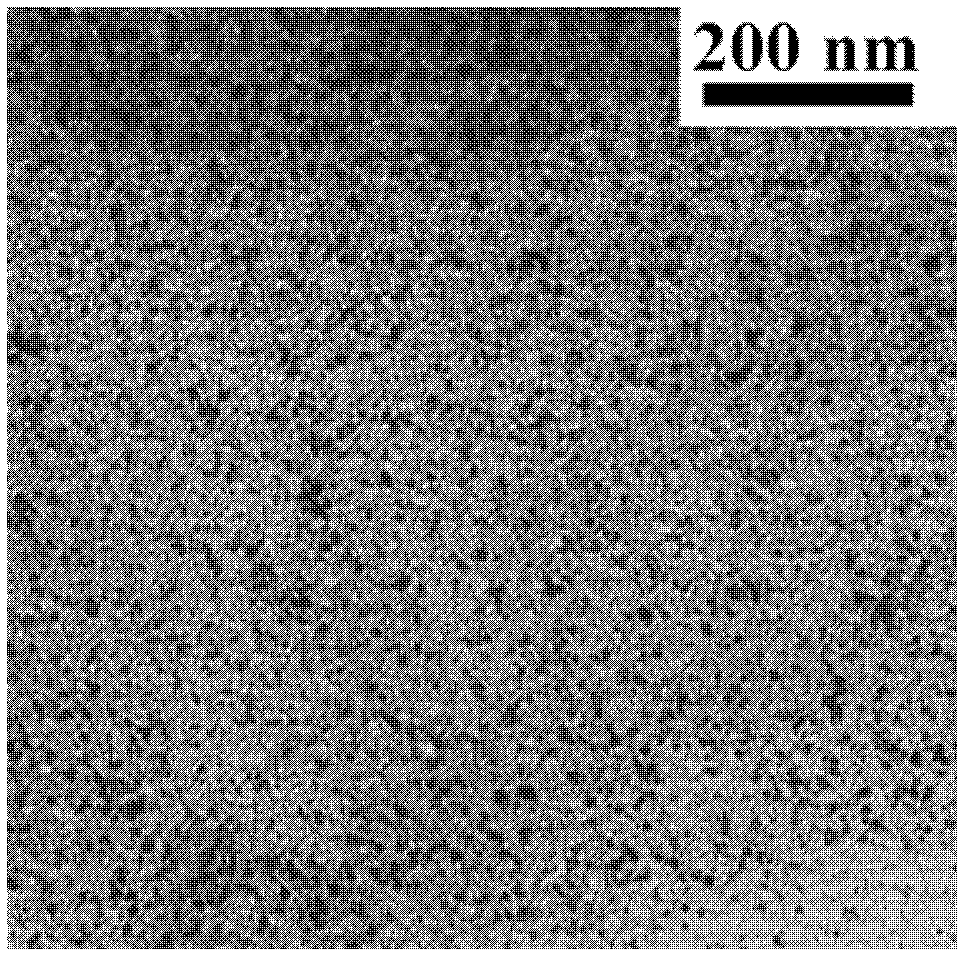

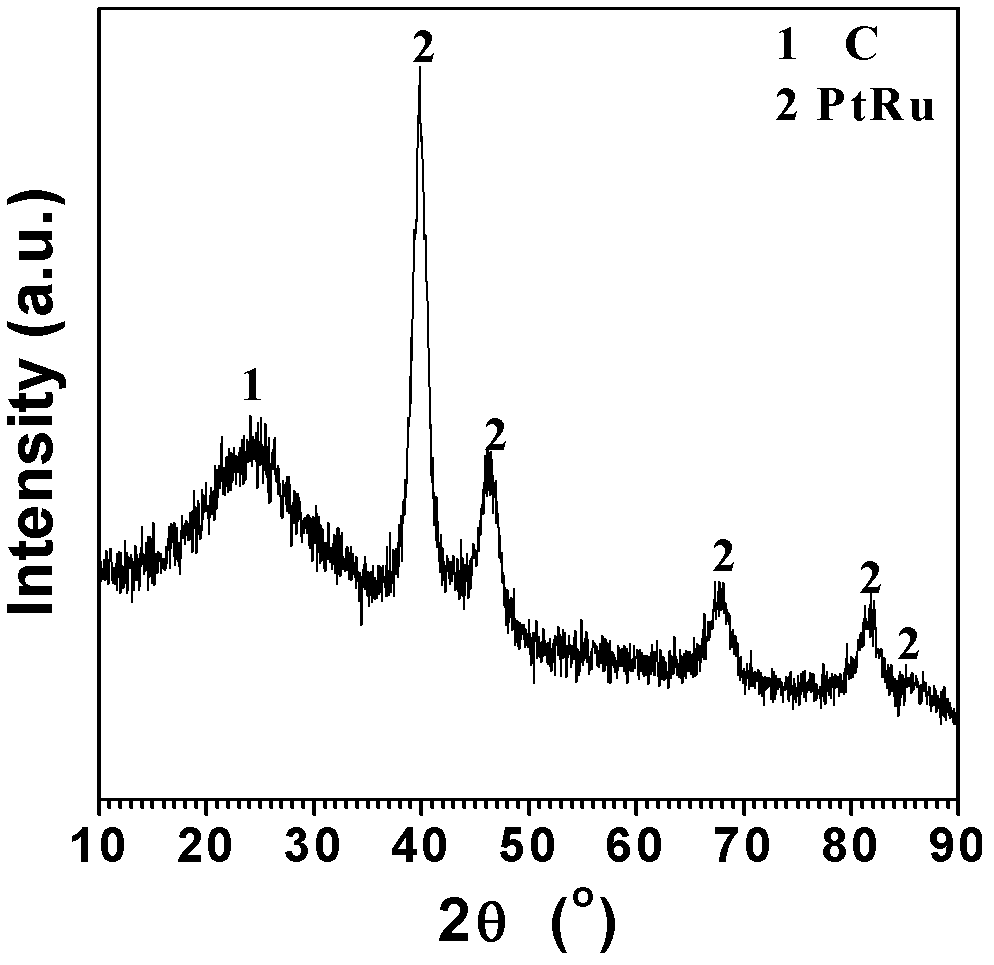

[0037] Weigh 50 mg 670 o C Preparation of carbon nanocages uniformly dispersed in 50 ml of ethylene glycol solution of chloroplatinic acid and ruthenium chloride, wherein the contents of Pt and Ru were 7.5 and 4.0 mg (molar ratio 1:1), under the protection of argon Stir for 3 hours, then heat up to 140 °C, react for 3 hours, filter and wash, dry at 110 °C to obtain Pt 1.0 Ru 1.0 / CNCs catalyst (see figure 2 , image 3 ). Platinum ruthenium nanoparticles have a good degree of dispersion, narrow particle size distribution, and a size of 1-10 nm.

[0038]

Embodiment 2

[0040] Weigh 50 mg of carbon nanocages and uniformly disperse them in 50 ml of ethylene glycol solution of potassium chloroplatinate and potassium chlororuthenate, in which the contents of Pt and Ru are 7.5 and 2.0 mg (molar ratio is 1:0.5), respectively. Stir for 3 hours under nitrogen protection, then heat up to 100 °C, react for 5 hours, filter and wash, and dry at 110 °C to obtain Pt 1.0 Ru 0.5 / CNCs catalyst. Platinum ruthenium nanoparticles have a good degree of dispersion, narrow particle size distribution, and a size of 1-10 nm.

[0041]

Embodiment 3

[0043] Weigh 50 mg 700 o C Preparation of carbon nanocages uniformly dispersed in 50 ml of ethylene glycol solution of platinum acetate and potassium chlororuthenate, in which the contents of Pt and Ru were 7.5 and 8.0 mg (molar ratio 0.5:1), under the protection of argon Stir for 3 hours, then raise the temperature to 180°C, react for 1 hour, filter and wash, and dry at 110°C to obtain Pt 0.5 Ru 1.0 / CNCs catalyst. Platinum ruthenium nanoparticles have a good degree of dispersion, narrow particle size distribution, and a size of 1-10 nm.

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com