Two-way operation grate-cleaning crusher

A two-way working, crusher technology, applied in the direction of grain processing, etc., can solve the problems of steel wheels derailing, delaying work, wasting workers' time, etc., to achieve compact travel drive and support mechanism, ensure reliability and high efficiency, and reduce wastage. The effect on the probability of smashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

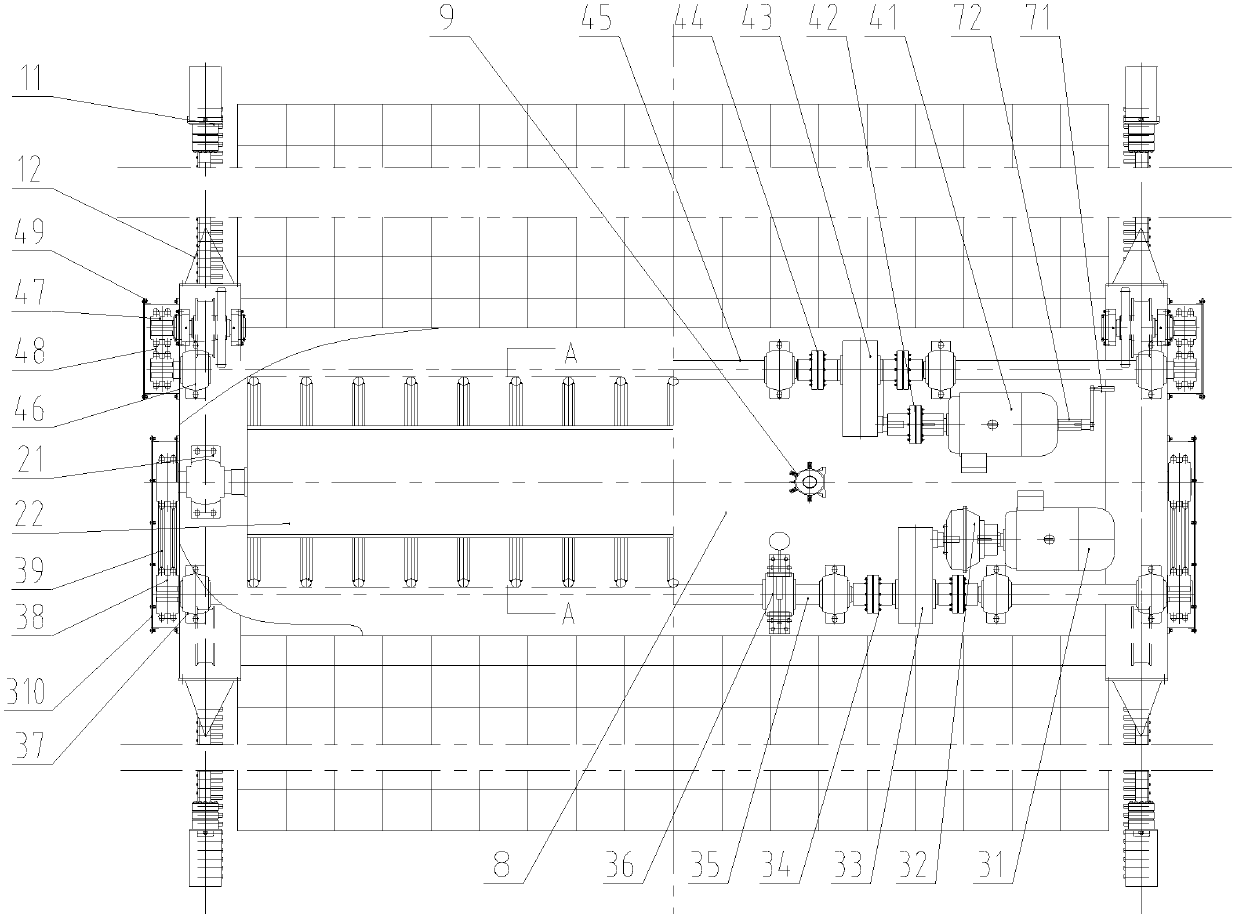

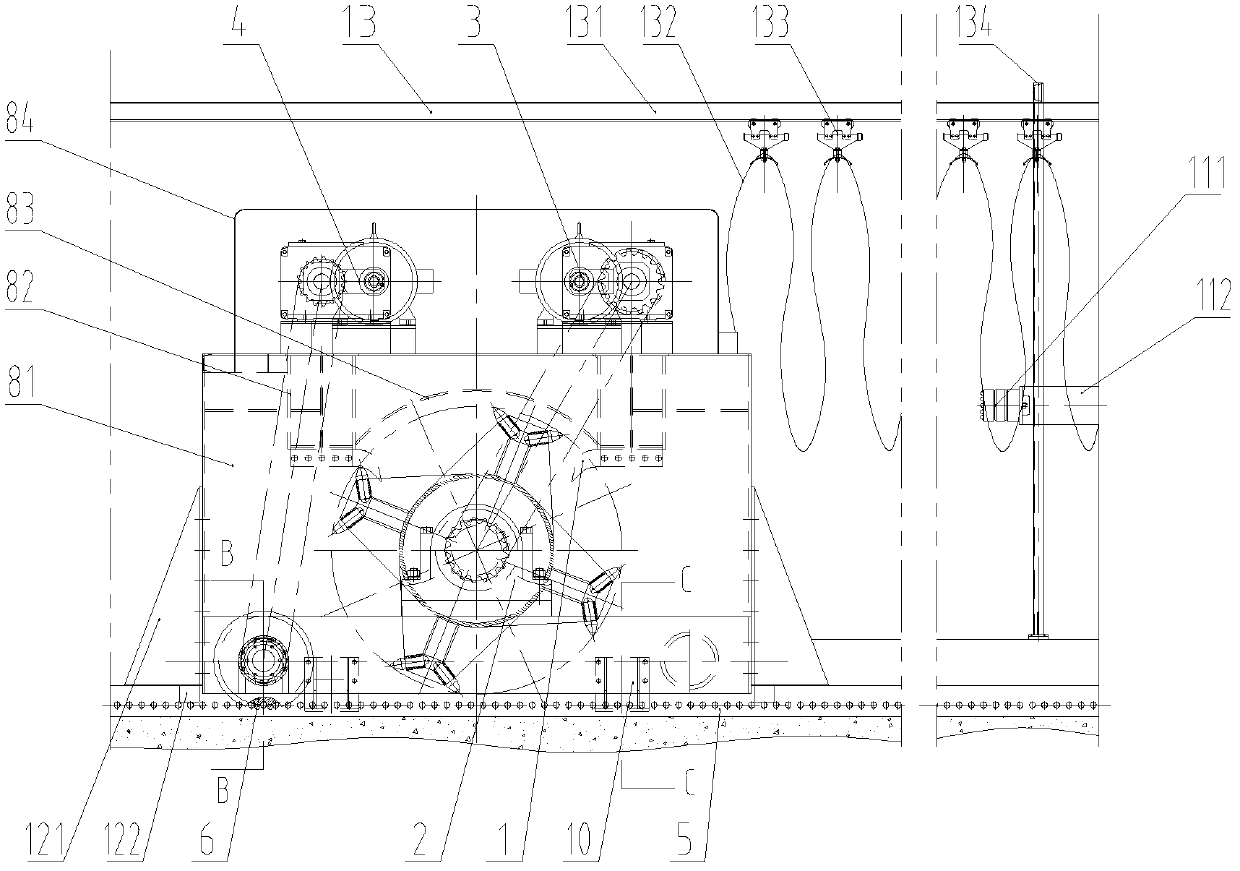

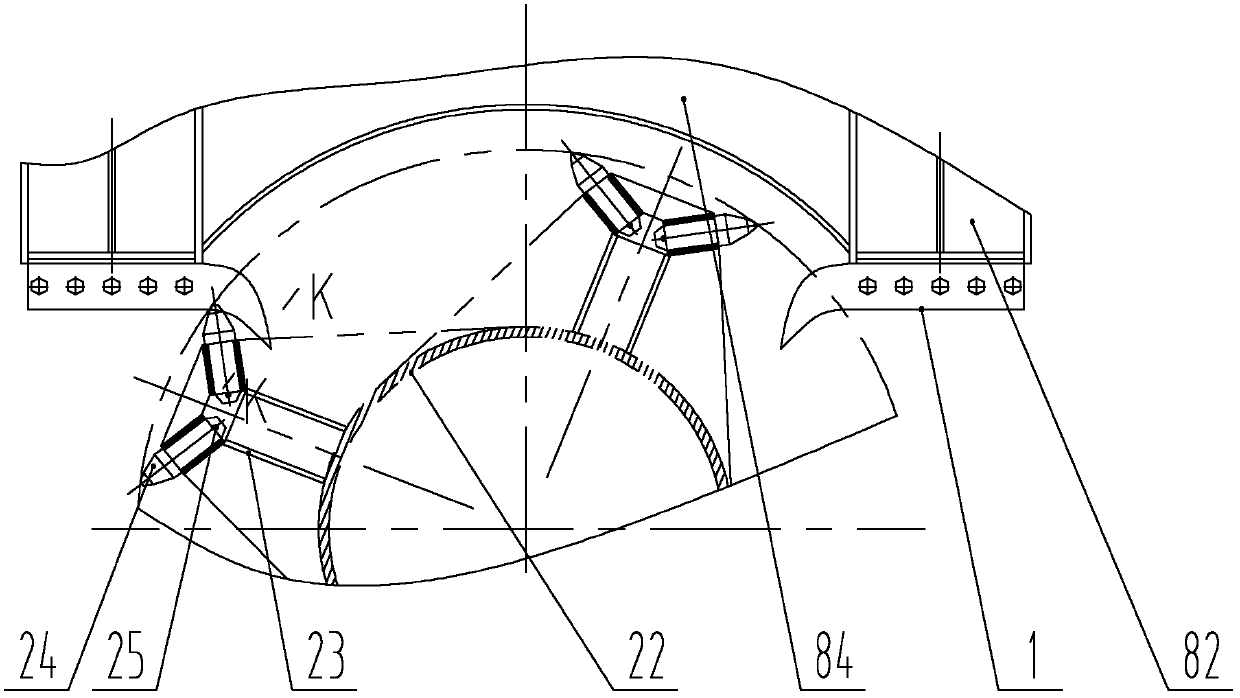

[0032] Below in conjunction with accompanying drawing, describe in detail the specific implementation of a kind of two-way work cleaning grate crusher.

[0033] Such as figure 1 , 2, 3, the two-way work cleaning grate crusher includes a two-way crushing roller mechanism 2, a travel support mechanism 5, a frame 8, a buffer mechanism 11 and a power supply device 13, a crushing transmission mechanism 3, a travel transmission mechanism 4 and an automatic lubrication system 9 is arranged on the bridge-type frame 8, and the four traveling driving mechanisms 6 are respectively arranged at the lower part of the two ends of the end beam 81, two of the traveling driving mechanisms 6 are not provided with gears 64, and the traveling driving mechanisms 6 are arranged on the traveling supporting mechanism 5 , driven by the walking transmission mechanism 4, the walking support mechanism 5 is set on the screen grate, the two-way crushing roller mechanism 2 is supported on the end beams 81 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com