Preparation method of tungsten oxide nano powder and metal tungsten nano powder

A nano-powder, tungsten oxide technology, applied in tungsten oxide/tungsten hydroxide, nanotechnology and other directions, can solve the problems of high production cost, high energy consumption, low metal tungsten conversion rate, etc., and achieve small size and uniform dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

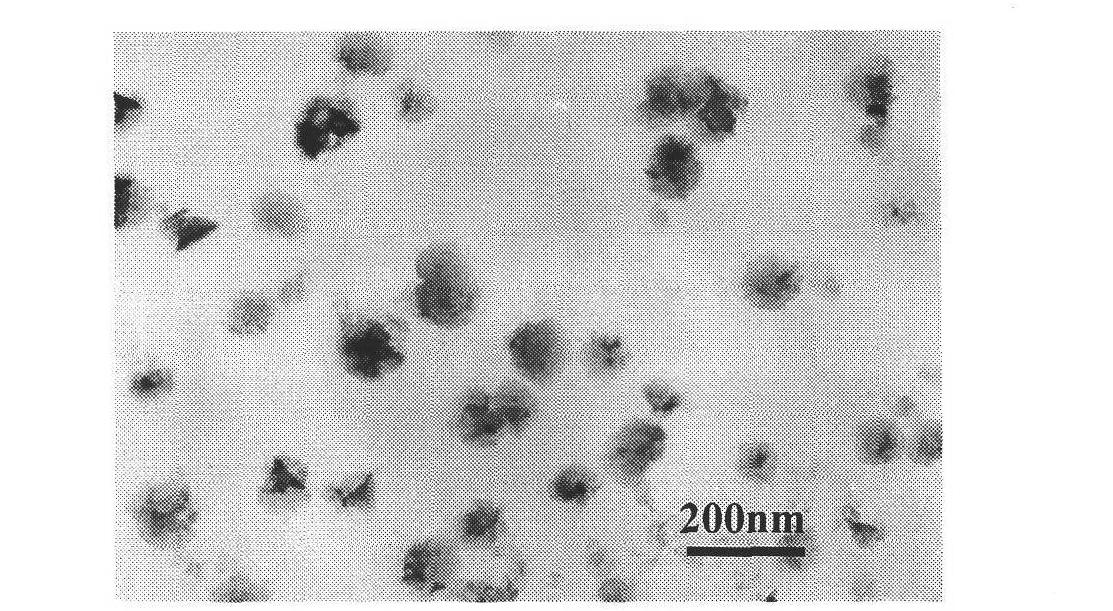

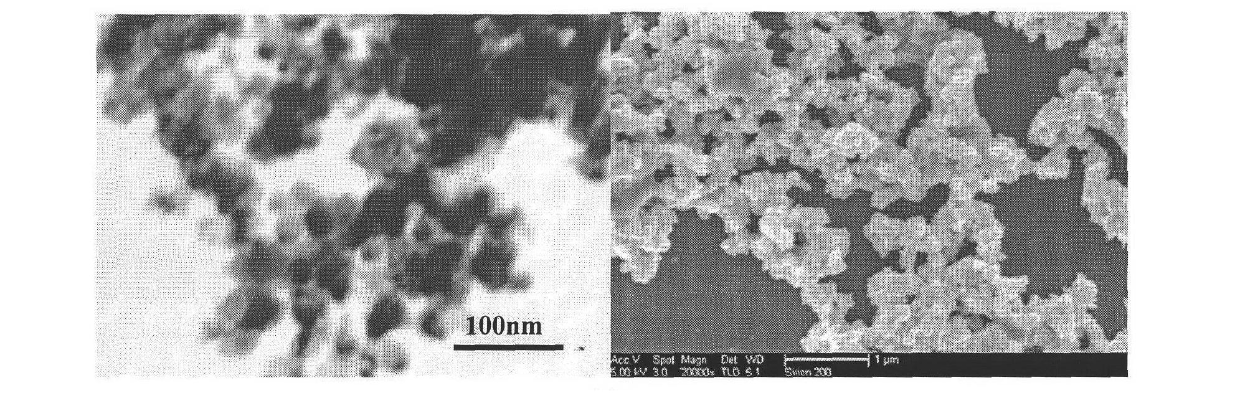

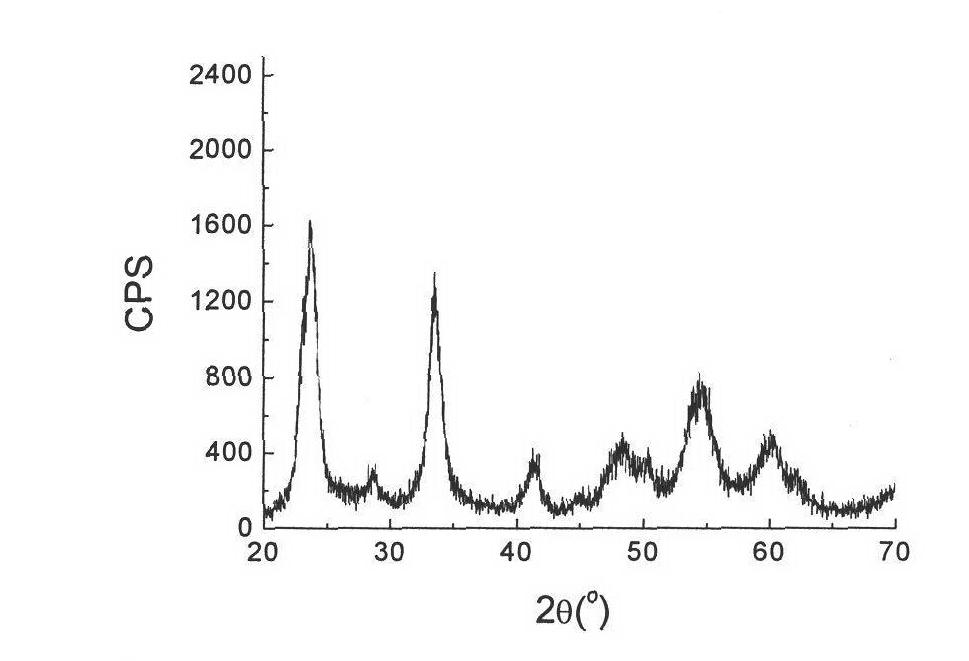

[0013] Example 1: Dissolve 1 part of sodium tungstate and 50 parts of inducer in 4500 parts of water, heat the above solution, then keep it warm at 100°C, and treat it with 2000 parts of acidic solution with pH=4, followed by precipitation reaction. After the reaction, the precipitate is filtered, washed and dried to obtain tungsten oxide nanopowder. The obtained tungsten oxide nanopowder was heated in H 2 Calcining at 1200° C. for 20 minutes in the atmosphere to obtain metal tungsten nanopowder.

Embodiment 2

[0014] Example 2: Dissolve 10 parts of potassium tungstate and 1 part of inducer in 100 parts of water, heat the above solution, then keep it warm at 100°C, and treat it with 10 parts of acidic solution with pH=1, and then a precipitation reaction occurs. After the reaction, the precipitate is filtered, washed and dried to obtain tungsten oxide nanopowder. The obtained tungsten oxide nanopowder was calcined at 650° C. for 30 minutes in a CO atmosphere to obtain metal tungsten nanopowder.

Embodiment 3

[0015] Example 3: Dissolve 10 parts of ammonium tungstate and 1 part of inducer in 100 parts of water, heat the above solution, then keep it warm at 50°C, and treat it with 10 parts of acidic solution with pH=1, and then a precipitation reaction occurs. After the reaction was over, the precipitate was filtered and washed, and the filter cake was placed in N 2 The temperature was kept at 500° C. for 20 minutes to obtain tungsten oxide nanopowder. The obtained tungsten oxide nanopowder was heated in H 2 Calcining at 600° C. for 40 minutes in the atmosphere to obtain metal tungsten nanopowder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com