Concrete acoustic material and manufacturing method thereof

A sound-absorbing material and concrete technology, which is applied in the field of noise pollution control, can solve the problems of low mechanical properties of sound-absorbing materials, complex and cumbersome production process, and low sound absorption coefficient, and achieve good sound-absorbing effect, simple manufacturing, and simple molding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

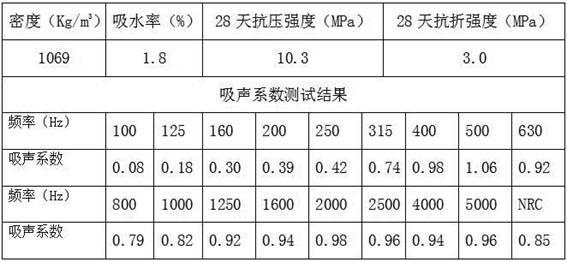

Embodiment 1

[0024] A concrete sound-absorbing material includes the following raw materials in parts by weight (1 kg per part): 100 parts of cement, 130 parts of ceramsite (grain gradation 4-8 mm: 70%, below 4 mm: 30%), polycarboxylate 1 part of acid water reducer, 0.5 part of silane water repellent, 0.25 part of polyester fiber, 0.1 part of latex powder, among which, the cement adopts PII low-alkali Portland cement with a strength grade of 52.5, and the water reducing rate of polycarboxylate water reducer More than 25%, the solid content of the silane waterproofing agent is ≥60%, the fiber length of the polyester fiber is 2-12 mm, and the latex powder is redispersible latex powder. The manufacturing method and steps of this concrete sound-absorbing material are as follows: A. Mix cement ceramsite, polycarboxylate water reducer, silane waterproofing agent, polyester fiber, and latex powder according to the above weight ratio to become dry powder; B. Make the mold according to the size req...

Embodiment 2

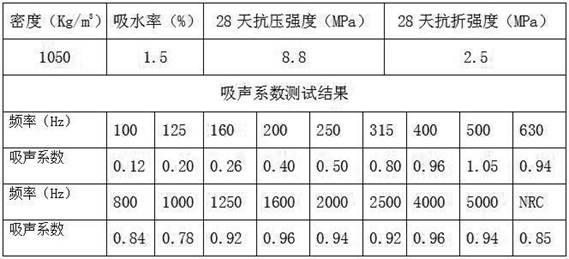

[0031] The manufacturing method and steps of this example are the same as those of Example 1, only the raw materials and proportions are different. The concrete sound-absorbing material in this example includes the following raw materials in parts by weight (1 kg per part): PII with a strength grade of 42.5 Portland cement 100 parts, ceramsite (grain gradation 4-8 mm: 50%, 4 mm or less: 50%) 145 parts, polycarboxylate water reducing agent 0.5 part, silane waterproofing agent 0.8 part, polyester fiber 0.2 part, 0.15 part of latex powder, and 20 parts of water.

[0032] The performance test results of the concrete sound-absorbing material prepared in this embodiment are shown in Table 2.

[0033] Table 2

[0034]

Embodiment 3

[0036] The manufacturing method and steps of this example are the same as those of Example 1, only the raw materials and proportions are different. The concrete sound-absorbing material in this example includes the following raw materials in parts by weight (1 kg per part): PO with a strength grade of 52.5 Ordinary Portland cement 100 parts, ceramsite (grain gradation 4-8 mm: 65%, below 4 mm: 35%) 155 parts, silane waterproofing agent 1 part, polyester fiber 0.5 part, latex powder 0.2 part, water 28 servings.

[0037] The performance test results of the concrete sound-absorbing material prepared in this embodiment are shown in Table 3.

[0038] table 3

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com