Neodymium niobic acid microwave dielectric ceramic with high quality factor and method for preparing neodymium niobic acid microwave dielectric ceramic

A microwave dielectric ceramic, high quality factor technology, applied in the field of ceramic compositions to achieve the effect of increasing bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

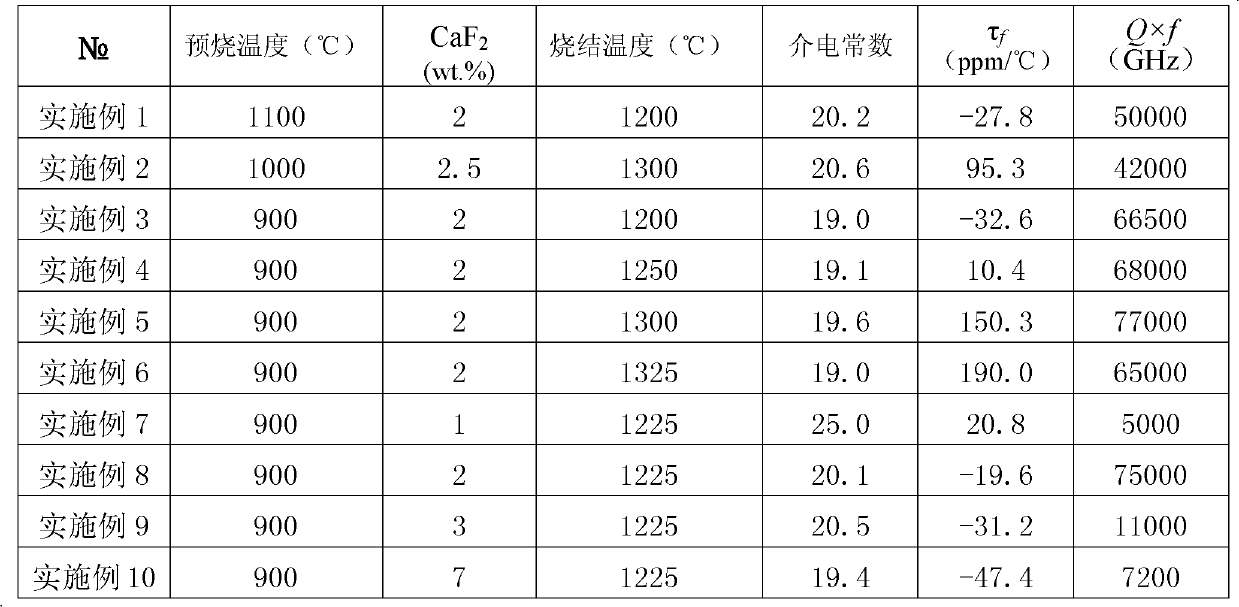

Examples

Embodiment 1

[0025] According to microwave dielectric ceramic composition NdNbO 4 , weigh Nd 2 o 3 11.17g, Nb 2 o 5 8.83g of ingredients, mixed powder into polyester tank, add 150ml of deionized water and 150g of zirconium balls, ball mill on planetary ball mill for 6 hours at 1000rpm, and place in a drying oven at 120°C after discharging Dry and pass through a 40-mesh sieve, calcinate the powder at 1100 ° C for 4 hours, then weigh 0.4 g of CaF2 with a weight percentage of 2% and mix it with the powder, and then ball mill it for 24 hours. Adding the paraffin wax of 8% by weight in the mixture is carried out granulation as a binding agent, and crosses 80 mesh sieves, is pressed into the green body that diameter is 10mm with the pressure of 4MPa again with powder tablet machine, and thickness is 5mm, and green body is in Sintered at 1200°C and held for 4 hours to prepare microwave dielectric ceramics, and the microwave dielectric properties of the samples were measured.

Embodiment 2

[0027] According to microwave dielectric ceramic composition NdNbO 4 , weigh Nd 2 o 3 11.17g, Nb 2 o 5 8.83g of ingredients, mixed powder into polyester tank, add 150ml of deionized water and 150g of zirconium balls, ball mill on planetary ball mill for 6 hours at 1000rpm, and place in a drying oven at 120°C after discharging Dry and pass through a 40-mesh sieve, calcinate the powder at 1000°C for 4 hours, then weigh 0.5g of CaF2 with a weight percentage of 2.5% and mix it with the powder, then ball mill it for 24 hours, dry it after discharging and put it in the powder Adding the paraffin wax of 8% by weight in the mixture is carried out granulation as a binding agent, and crosses 80 mesh sieves, is pressed into the green body that diameter is 10mm with the pressure of 4MPa again with powder tablet machine, and thickness is 5mm, and green body is in Sintered at 1300°C and held for 4 hours to prepare microwave dielectric ceramics, and the microwave dielectric properties of...

Embodiment 3

[0029] According to microwave dielectric ceramic composition NdNbO 4 , weigh Nd 2 o 3 11.17g, Nb 2 o 5 8.83g of ingredients, mixed powder into polyester tank, add 150ml of deionized water and 150g of zirconium balls, ball mill on planetary ball mill for 6 hours at 1000rpm, and place in a drying oven at 120°C after discharging Dry and pass through a 40-mesh sieve, calcinate the powder at 900°C for 4 hours, and then weigh 2% CaF 2 0.4g is mixed with the powder and then ball milled for 24 hours for 24 hours. After the material is discharged, it is dried and 8% by weight of paraffin is added to the powder as a binder for granulation. After passing through an 80-mesh sieve, the powder is pressed into tablets Press the machine into a green body with a diameter of 10mm and a thickness of 5mm at a pressure of 4MPa. The green body was sintered at 1200°C and kept for 4 hours to obtain a microwave dielectric ceramic. The microwave dielectric properties of the sample were measured. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com