Light-blocking PE (polyethylene) film for food packaging

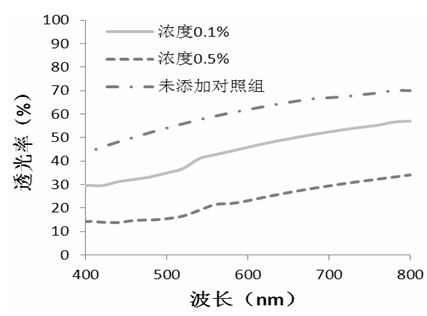

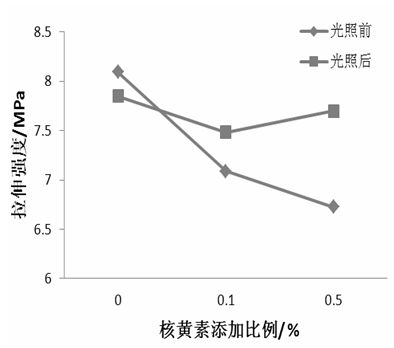

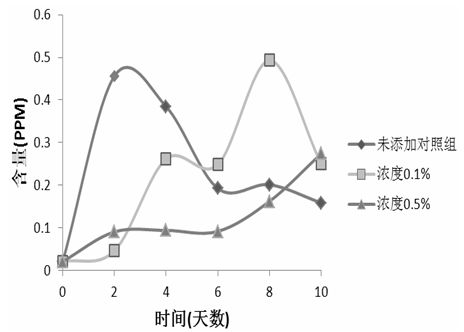

A food packaging and light-blocking technology, which is applied in the field of food packaging materials, can solve the problems of increased light oxidation reaction to product hazards, riboflavin addition, etc., and achieve the effect of inhibiting photoaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Take 25g of riboflavin (product number 67001734, produced by Sinopharm Chemical Reagent Co., Ltd.), and take 25000g of PE masterbatch (Q / 3201-BYC-01 low-density polyethylene , produced by Yangzi Petrochemical-BASF Co., Ltd.), mix the two evenly, and place them in a double-roller plastic refining machine (SK-160B double-roller plastic refining machine, produced by Shanghai Rubber Machinery Factory) for plastic refining and extrusion. Outlet temperature 130°C;

[0021] (2) Take 6.5g of extruded material and put it in the center of the two pressure plates (the size of the inner template of the pressure plate is 20cm×14cm, and the thickness is about 350μm), and place the pressure plate on the flat vulcanizing machine (XLB-Q500×500×2 flat vulcanizing machine, Manufactured by Wenlin Chemical Machinery Factory, Jiangyin City, Jiangsu Province), the hot pressing temperature is 155°C, the hot pressing pressure is 0.4Mpa, and pre-pressed for 4 minutes under these conditions, ...

Embodiment 2

[0024] (1) Take 25g of riboflavin (product number 67001734, produced by Sinopharm Chemical Reagent Co., Ltd.), and take 5000g of PE masterbatch (Q / 3201-BYC-01 low-density polyethylene , produced by Yangzi Petrochemical-BASF Co., Ltd.), mix the two evenly, and place them in a double-roller plastic refining machine (SK-160B double-roller plastic refining machine, produced by Shanghai Rubber Machinery Factory) for plastic refining and extrusion. Outlet temperature 140°C;

[0025] (2) Take 6.5g of extruded material and put it in the center of the two pressure plates (the size of the inner template of the pressure plate is 20cm×14cm, and the thickness is about 350μm), and place the pressure plate on the flat vulcanizing machine (XLB-Q500×500×2 flat vulcanizing machine, Manufactured by Wenlin Chemical Machinery Factory, Jiangyin City, Jiangsu Province), the hot-pressing temperature is 165°C, and the hot-pressing pressure is 0.6Mpa. Under these conditions, it is pre-pressed for 3 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com