Fast response liquid crystal material for liquid crystal wave-front corrector and preparation method thereof

A technology for wavefront correctors and liquid crystal materials, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve problems such as high Δn, unspecified composition and ratio of liquid crystal mixtures, and failure to satisfy liquid crystal wavefront correctors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

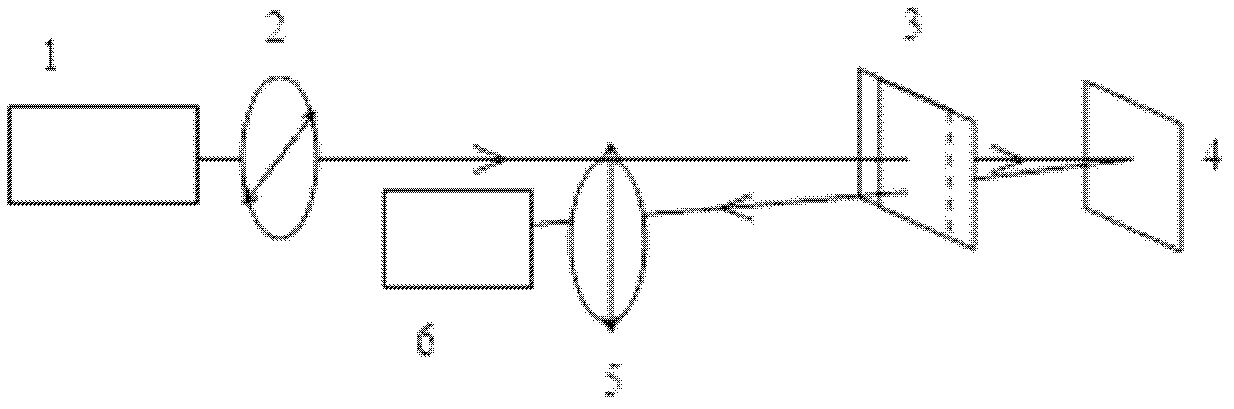

Method used

Image

Examples

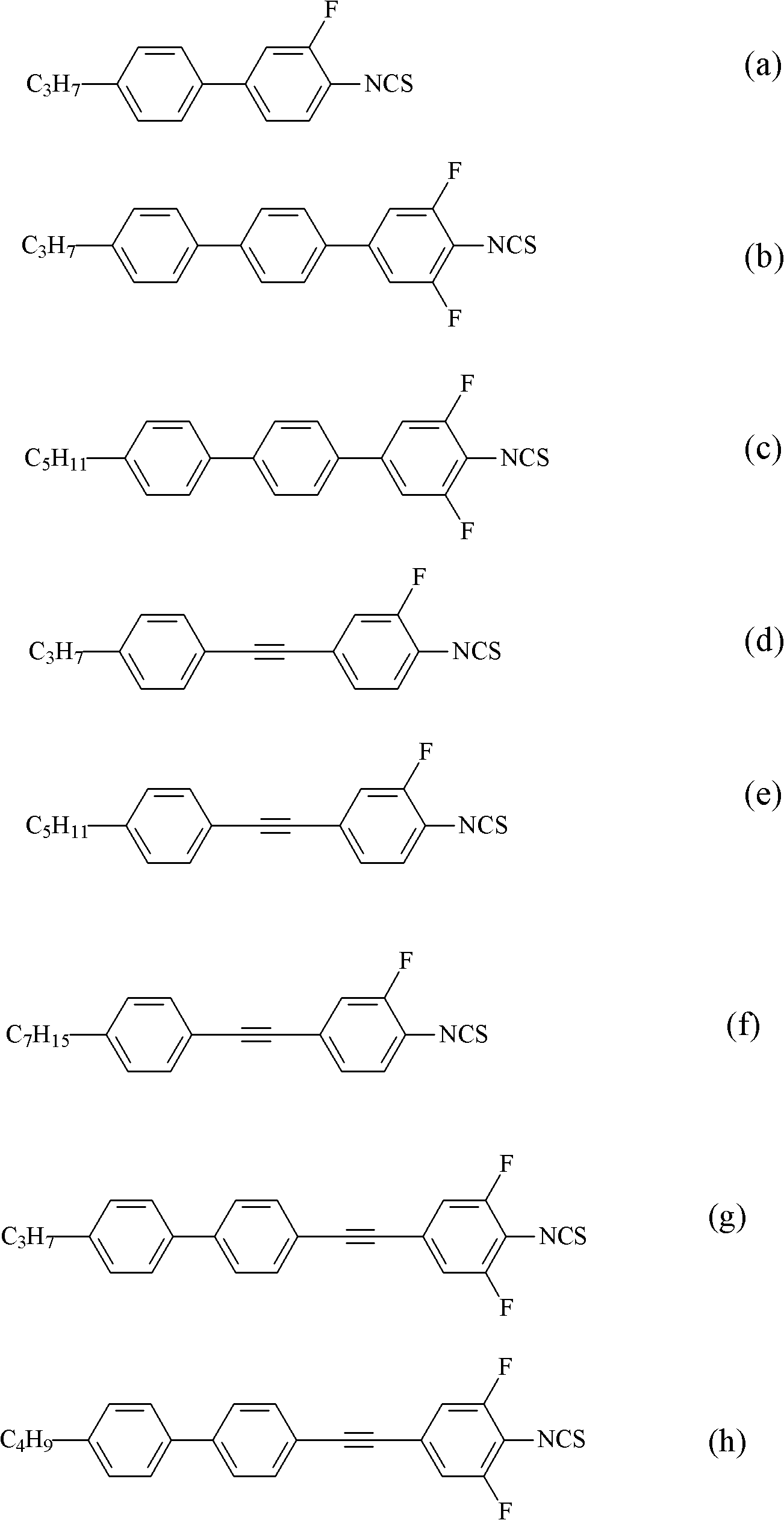

Embodiment 1

[0020] According to the weight percentage of the mixture: (a) 5%, (b) 8%, (c) 7%, (d) 11%, (e) 33%, (f) 22%, (g) 7%, (h ) 7%, weighed 0.0500g from the synthesized (a) compound, weighed 0.0800g from the (b) compound, weighed 0.0700g from the (c) compound, and weighed 0.1100g from the (d) compound with an analytical balance. (e) weigh 0.3300 g of the compound, (f) weigh 0.2200 g of the compound, weigh 0.0700 g of the (g) compound, and weigh 0.0700 g of the (h) compound. Put the weighed eight compounds into a borosilicate glass reagent bottle with a volume of 5mL, add a polytetrafluoroethylene stirring bar with a length of 5mm, and cover the bottle cap with a polytetrafluoroethylene sealing inner gasket; place the reagent bottle in In a 60° C. water bath, electromagnetically stirred for 1 hour, all the solids were dissolved, and the target liquid crystal material was obtained, which is called liquid crystal S1.

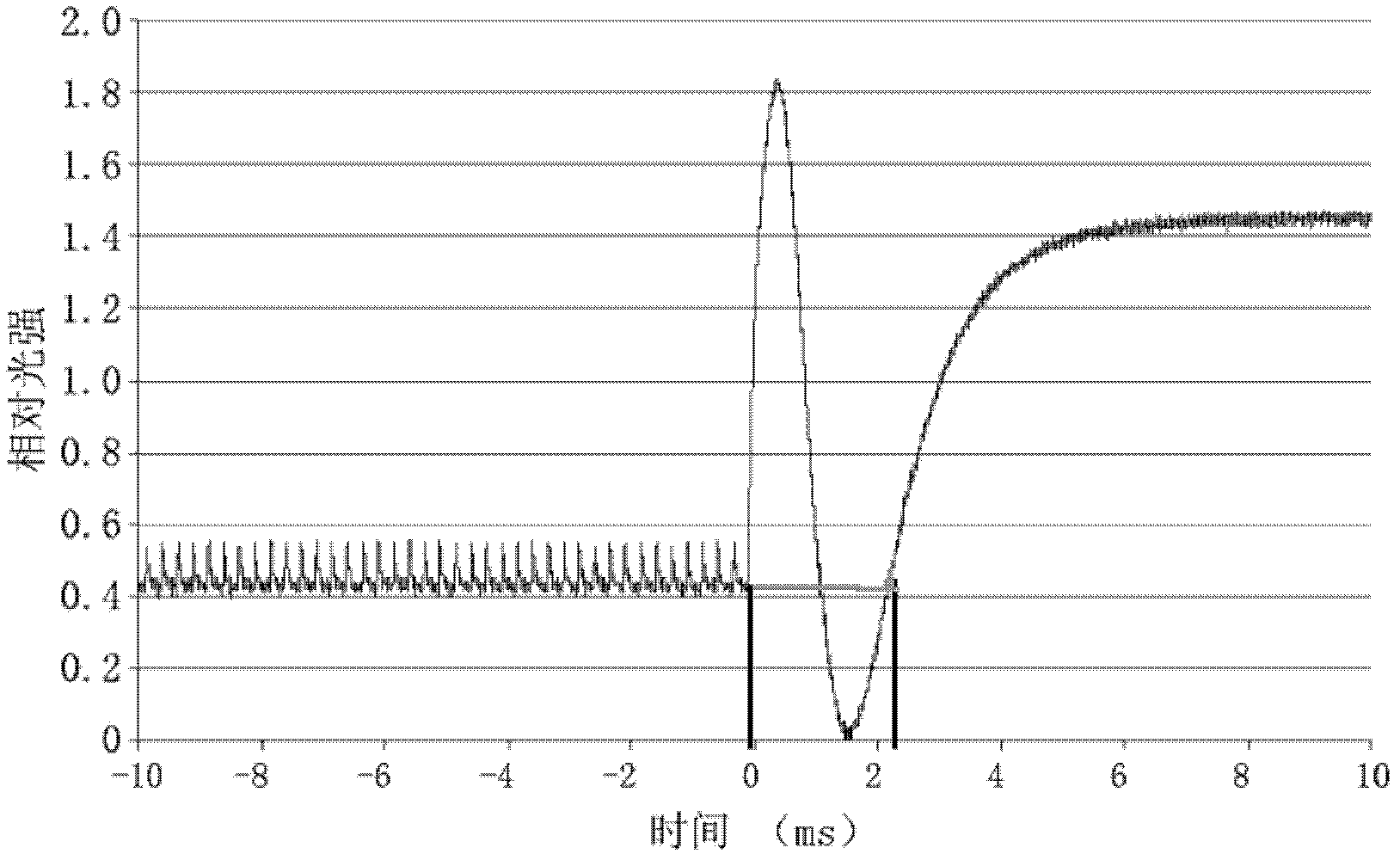

[0021] Detect the physical characteristics of liquid crystal S1: ...

Embodiment 2

[0030] According to the weight percentage of the mixture: (a) 3%, (b) 7%, (c) 6%, (d) 11%, (e) 33%, (f) 22%, (g) 9%, (h ) 9%, weigh 0.0300g from the synthesized (a) compound, 0.0700g from the (b) compound, 0.0600g from the (c) compound, and 0.1100g from the (d) compound with an analytical balance. (e) weigh 0.2200 g of the compound, (f) weigh 0.3300 g of the compound, weigh 0.0900 g of the (g) compound, and weigh 0.0900 g of the (h) compound. Put the weighed eight compounds into a borosilicate glass reagent bottle with a volume of 5mL, add a polytetrafluoroethylene stirring bar with a length of 5mm, and cover the bottle cap with a polytetrafluoroethylene sealing inner gasket; place the reagent bottle in In a 60° C. water bath, electromagnetically stirred for 1 hour, all the solids were dissolved, and the target liquid crystal material was obtained, which is called liquid crystal S2.

[0031] Detect the physical characteristics of liquid crystal S2:

[0032] (1) Nematic phase...

Embodiment 3

[0039] According to the weight percentage of the mixture: (a) 6%, (b) 8%, (c) 7%, (d) 12%, (e) 34%, (f) 23%, (g) 5%, (h ) 5%, use an analytical balance to weigh 0.0600g from the synthesized (a) compound, 0.0800g from the (b) compound, 0.0700g from the (c) compound, and 0.1200g from the (d) compound, (e) weigh 0.3400 g of the compound, (f) weigh 0.2300 g of the compound, weigh 0.0500 g of the (g) compound, and weigh 0.0500 g of the (h) compound. Put the weighed eight compounds into a borosilicate glass reagent bottle with a volume of 5mL, add a polytetrafluoroethylene stirring bar with a length of 5mm, and cover the bottle cap with a polytetrafluoroethylene sealing inner gasket; place the reagent bottle in In a 60° C. water bath, electromagnetically stirred for 1 hour, all the solids were dissolved, and the target liquid crystal material was obtained, which is called liquid crystal S3.

[0040] Detect the physical characteristics of liquid crystal S3:

[0041] (1) Nematic pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com