Shield machine base bearing special-purposed sealing grease and preparation method thereof

A sealing grease and main bearing technology, which is applied in the petroleum industry, lubricating composition, etc., can solve the problem that the lubricity of the pumpable sealing material is not enough to meet the technical requirements of the main bearing of the shield machine, the loss of the shield machine, and the difficulty of replacing maintenance parts And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In embodiment 1, the following components are used to prepare the sealant of the present invention, wherein the percentage is based on the total weight of the sealant: pentaerythritol oleate 38.0%, YYD-15 wood fiber (Langfang Yiyuedi Chemical Industry Co., Ltd. Co., Ltd. production, fiber length 1.5mm) 8.0%, polybutene PB1400 10.0%, BT-838S organobentonite 5.5%, No. 0 molybdenum disulfide 6.0%, barium sulfate 32.5%.

[0022] The preparation method is as follows: put pentaerythritol oleate and polybutene PB1400 into the stirring mixer, stir and heat up to 80°C, add YYD-15 wood fiber, control the temperature at 80-90°C and stir for 45 minutes, add BT-838S organic Bentonite, after stirring for 45 minutes, add barium sulfate and No. 0 molybdenum disulfide, and stir and mix at 80-90°C for 120 minutes.

Embodiment 2

[0024] In this embodiment, the following components are used to prepare the sealant of the present invention, and the percentages are based on the total weight of the sealant: polyalphaolefin PAO 942.0%, sepiolite fiber 9.0%, PRS-A1100 Refined C5 petroleum resin 7.0%, CAB-O-SIL M-5 fumed silica 6.0%, No. 0 colloidal graphite 6.0%, zinc sulfate 10.0%, barium sulfate 20.0%.

[0025] The preparation method is: put PAO 9 and PRS-A1100 refined C5 petroleum resin into the stirring mixer, stir and heat up to 90°C, after the PRS-A1100 refined C5 petroleum resin is completely dissolved, add sepiolite fiber, and control the temperature at 80~ Stir at 90°C for 60 minutes, add CAB-O-SIL M-5 fumed silica, stir for 30 minutes, then add zinc sulfate, barium sulfate and No. 0 colloidal graphite, stir and mix at 80-90°C for 120 minutes.

Embodiment 3

[0027] In this embodiment, the following components are used to prepare the sealant of the present invention, and the percentages are based on the total weight of the sealant: isooctyl oleate 30.0%, polyalpha-olefin PAO 2510.5%, YYD- 15 Wood fiber 4.0%, sepiolite fiber 5.0%, polybutene PB2400 9.0%, BT-838S organic bentonite 6.0%, No. 0 molybdenum disulfide 4.5%, Dyneon TF-9207 polytetrafluoroethylene powder (purchased from 3M company) 2.0%, calcium carbonate 8.0%, barium sulfate 21.0%.

[0028]The preparation method is as follows: put isooctyl oleate, PAO 25, and PB2400 into the stirring mixer, stir and heat up to 70°C, after mixing evenly, add YYD-15 into the wood fiber and sepiolite fiber, and control the temperature at 70°C Stir at ~80°C for 45 minutes, add BT-838S organic bentonite, stir for 45 minutes, then add calcium carbonate, barium sulfate, Dyneon TF-9207 PTFE powder and No. 0 molybdenum disulfide, stir and mix at 70-80°C 90 minutes.

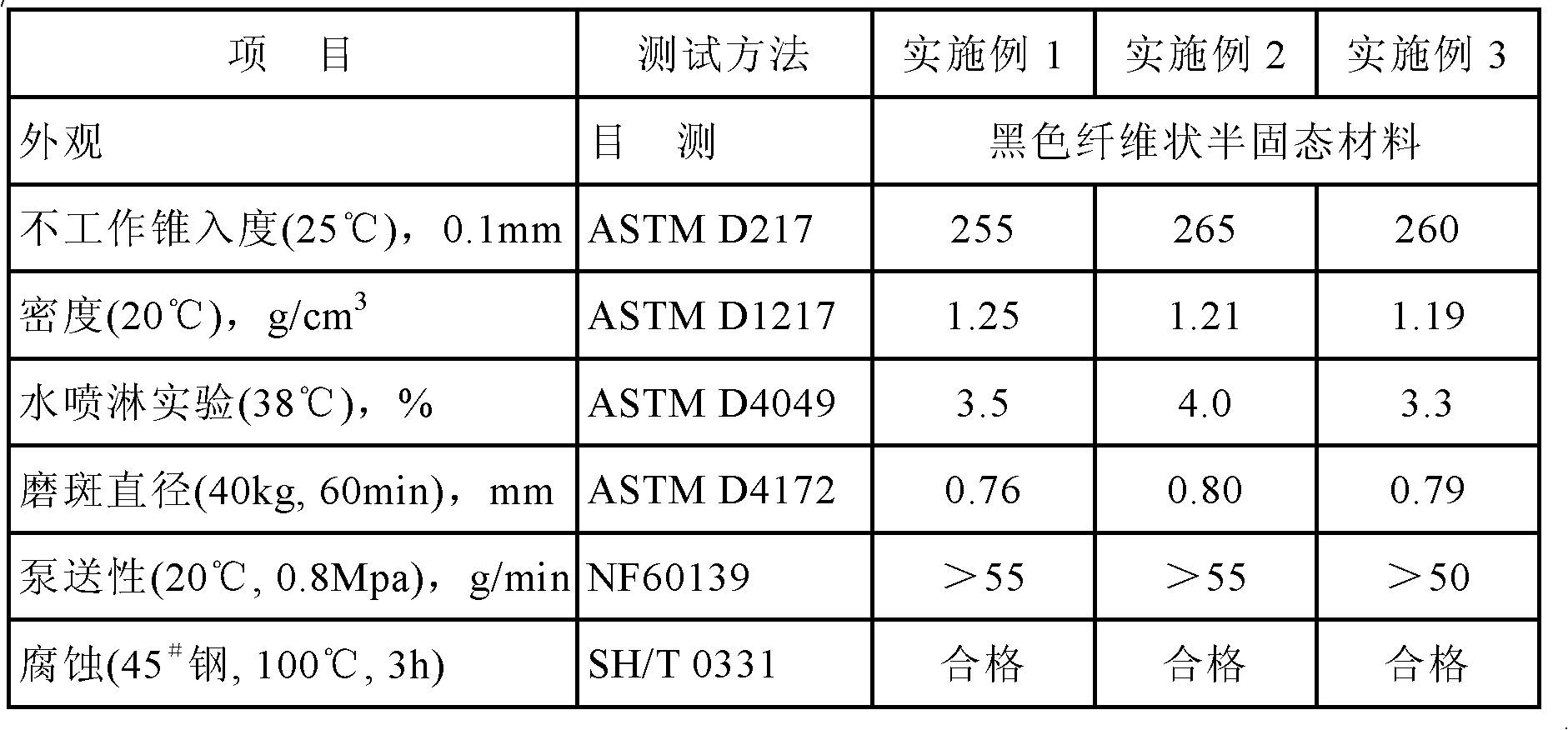

[0029] Various performance pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com