Preparation method of high purity zinc by vacuum distillation

A high-purity, vacuum technology, used in the improvement of process efficiency, crucible furnaces, furnaces, etc., can solve the problems that the product quality cannot be guaranteed, the temperature and volatilization conditions of the distillation furnace cannot be accurately controlled, and the process conditions are easy to control and separate. Good effect and easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

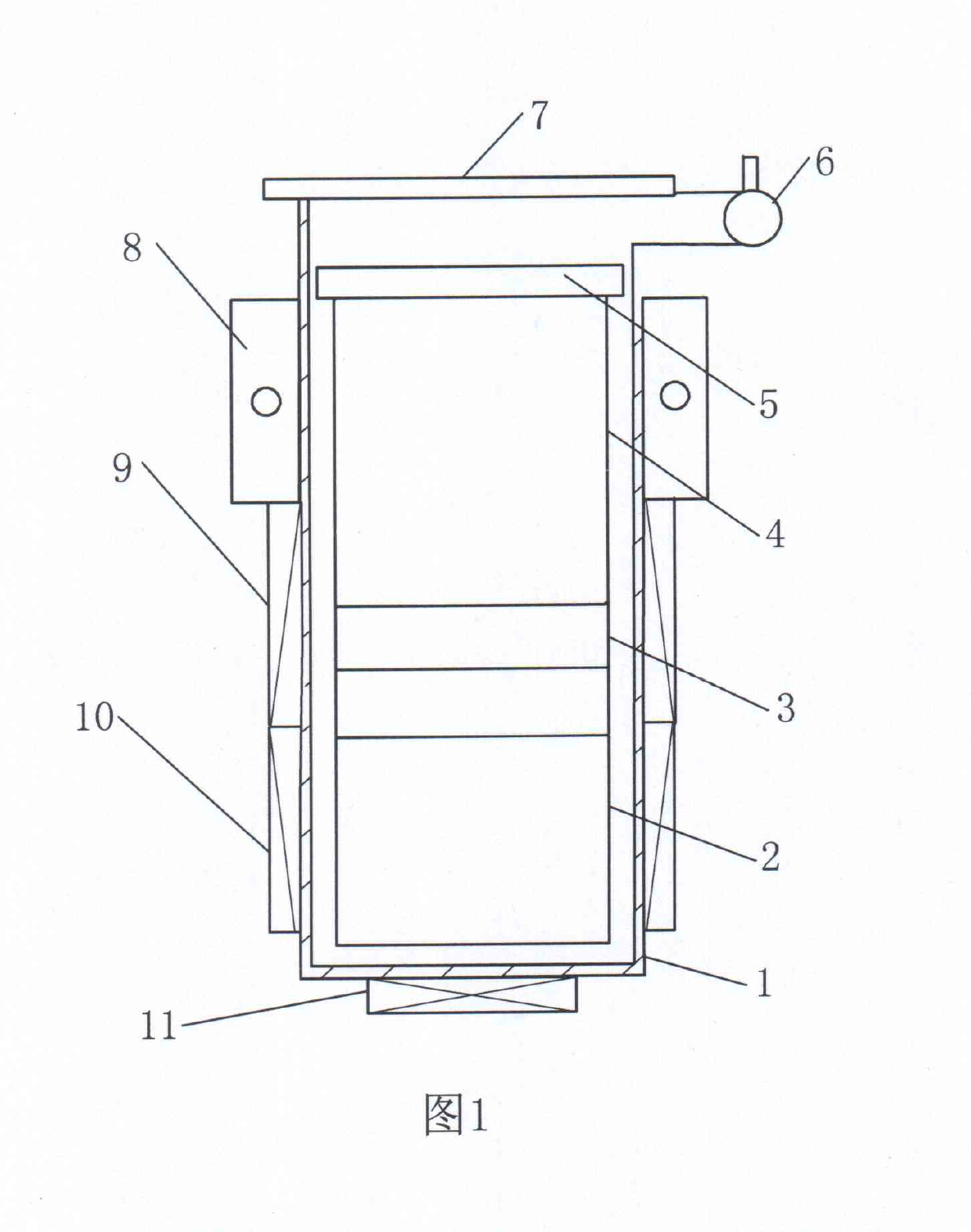

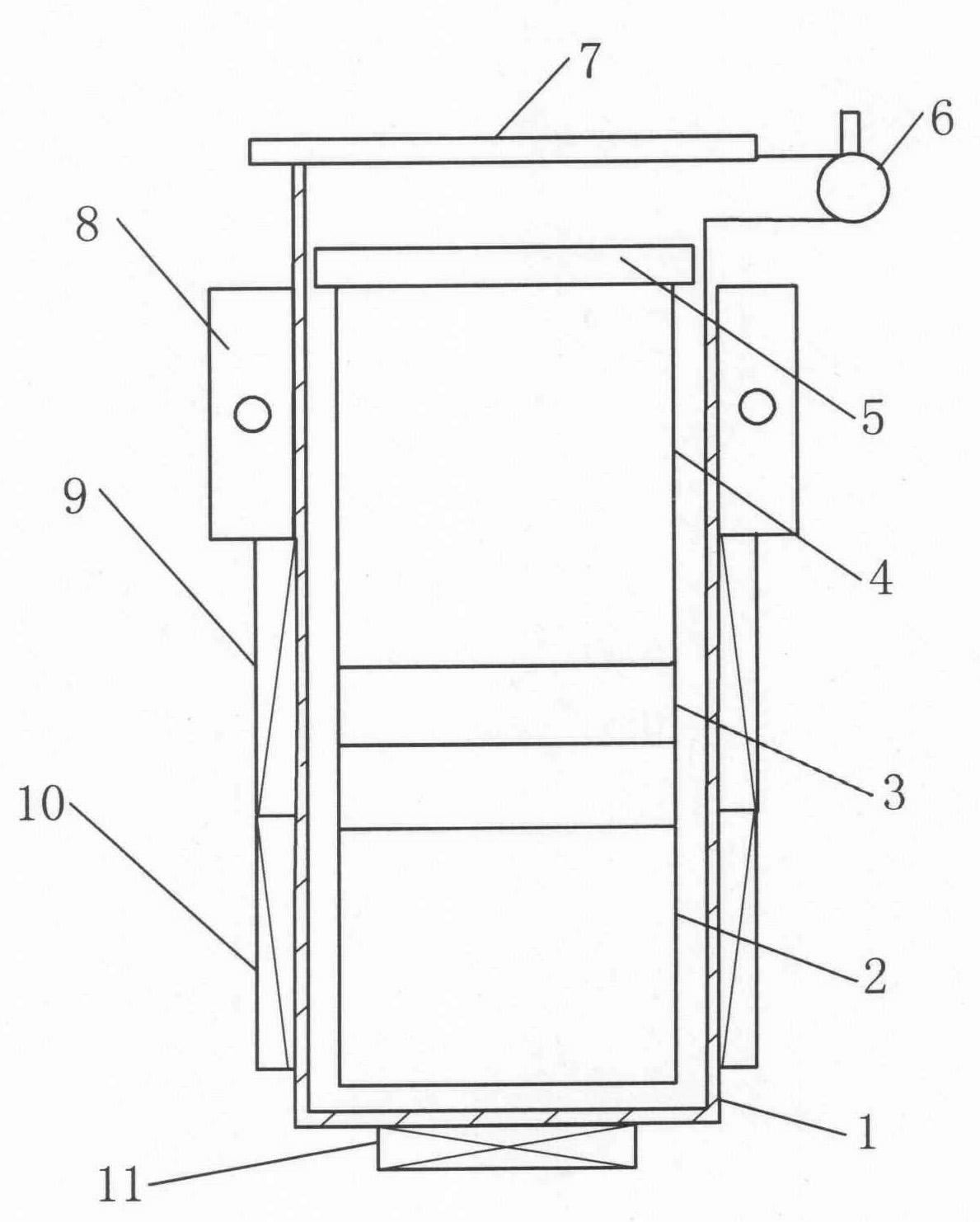

Image

Examples

Embodiment 1

[0045] Zinc raw material is 99.99% refined zinc, main impurity content: Pb: 0.005%, Cd: 0.003%, Fe: 0.003%, Cu: 0.002%, Sn: 0.001%, Al: 0.002%. The sum of impurities is 0.01%.

[0046] The process conditions are:

[0047] Crucible feeding 18Kg, distillation time 16h, distillation furnace upper temperature 360°C, lower temperature 460°C, silicon carbide rod heating voltage regulator output voltage 85V, vacuum degree ≤ -0.1Mpa.

[0048] The situation after operating according to this condition:

[0049] Volatile matter 0.3Kg, carbon residue 2.3Kg, 5N semi-finished product 15.4Kg.

[0050] The semi-finished product is sampled at the upper, middle and lower points to make a mixed sample, and then the impurities are detected by ICP-MS mass spectrometer as follows: Pb: 0.00015%, Cd: 0.00015%, Fe: 0.0001%, Cu: 0.00003%, Sn: 0.00001%, Al: 0.00005%, Ni: 0.00005%, Bi: 0.00001%, Mg: 0.00005%, As: 0.00005%, Cr: 0.00005%, Sb: 0.00005%. The sum of impurities is 0.0008%, meeting the requ...

Embodiment 2

[0052]Zinc raw material is 99.995% refined zinc, main impurity content: Pb: 0.003%, Cd: 0.002%, Fe: 0.001%, Cu: 0.001%, Sn: 0.001%, Al: 0.001%. The sum of impurities is 0.005%.

[0053] The process conditions are:

[0054] Crucible feeding 18Kg, distillation time 16h, distillation furnace upper temperature 370°C, lower temperature 470°C, silicon carbide rod heating voltage regulator output voltage 85V, vacuum degree ≤ -0.1Mpa.

[0055] The situation after operating according to this condition:

[0056] Volatile matter 0.3Kg, carbon residue 1.7Kg, 5N semi-finished product 16Kg.

[0057] The semi-finished product is sampled at the upper, middle and lower points to make a mixed sample, and then the impurities are detected by ICP-MS mass spectrometer as follows: Pb: 0.00015%, Cd: 0.00015%, Fe: 0.0001%, Cu: 0.00003%, Sn: 0.00001%, Al: 0.00005%, Ni: 0.00005%, Bi: 0.00001%, Mg: 0.00005%, As: 0.00005%, Cr: 0.00005%, Sb: 0.00005%. The sum of impurities is 0.0008%, meeting the requi...

Embodiment 3

[0059] Zinc raw material is 5N high-purity zinc semi-finished product.

[0060] The process conditions are:

[0061] Crucible feeding 18Kg, distillation time 16h, distillation furnace upper temperature 360°C, lower temperature 460°C, silicon carbide rod heating voltage regulator output voltage 85V, vacuum degree ≤ -0.1Mpa.

[0062] After operating according to this condition, the output situation: volatile matter 0.1Kg, carbon residue 2.4Kg, 6N semi-finished product 15.5Kg.

[0063] The product is made into a mixed sample by sampling at the upper, middle and lower points, and the impurities are detected by ICP-MS mass spectrometer as follows: Pb: 0.000025%, Cd: 0.000025%, Fe: 0.00001%, Cu: 0.000003%, Sn: 0.000001%, Al: 0.000005 % Ni: 0.000005%, Bi: 0.000002%, Mg: 0.000005%, As: 0.000001%, Cr: 0.000002%, Sb: 0.000005%. , the sum of impurities is 0.000089%, meeting the requirements of the standard Q / HX02.07-2007.

[0064] The mass percentage content of the 5N zinc zinc is: ≥9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com