Preparation method of magnetic metal or alloy film with nano-structure

A magnetic metal and alloy thin film technology, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of poor controllability of thin film microstructure, high equipment requirements, difficult preparation, etc. Good regularity, high film-forming strength, simple equipment and process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of magnetic nano-nickel thin film is:

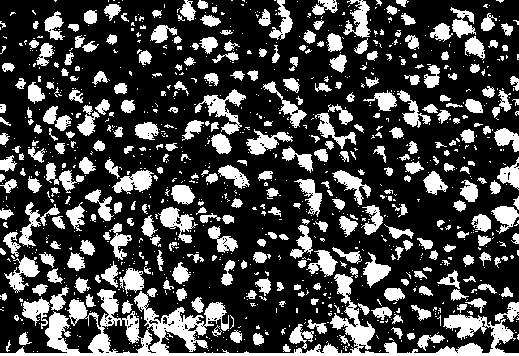

[0033] Take 4 mmol of nickel chloride and 6 mmol of disodium ethylenediaminetetraacetic acid (EDTA) in a beaker filled with 20ml of distilled water and stir, slowly drop into 10ml of 20mol / L sodium hydroxide solution, and then add 50% concentration of 10ml of hydrazine hydrate and 40ml of absolute ethanol were stirred to form a reaction solution. A piece of copper foil that has been cleaned by ultrasonic waves is attached to the inner wall of the reaction vessel and circles around the inner wall. Transfer the configured reaction solution into a reaction vessel, and seal the vessel. Put the container into the hollow position of the circular cylindrical magnet, transfer the reactor and the magnet together into an oven and heat to 100°C, and react for 8 hours. After the reaction, take out the film in the reaction vessel and wash it with distilled water and ethanol to obtain a nanostructured magnetic nickel film...

Embodiment 2

[0036] A preparation method of magnetic nano-cobalt film is:

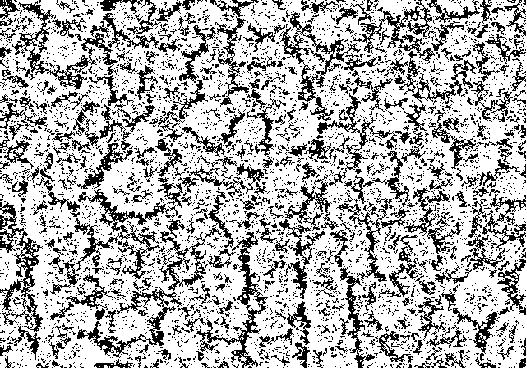

[0037]Take 4 mmol of cobalt chloride and 6 mmol of disodium ethylenediaminetetraacetic acid (EDTA) in a beaker filled with 20 ml of distilled water and stir, slowly drop into 10 ml of 20 mol / L sodium hydroxide solution, and then add 50% of 10ml of hydrazine hydrate and 40ml of absolute ethanol were stirred to form a reaction solution. A piece of copper foil that has been cleaned by ultrasonic waves is attached to the inner wall of the reaction vessel and circles around the inner wall. Transfer the configured reaction solution into a reaction vessel, and seal the vessel. Put the container into the hollow position of the circular cylindrical magnet, transfer the reactor and the magnet together into an oven and heat to 100°C, and react for 8 hours. After the reaction, take out the film in the reaction vessel and wash it with distilled water and ethanol to obtain a nanostructured magnetic cobalt film. The scanning el...

Embodiment 3

[0040] A preparation method of a magnetic nano-nickel-cobalt alloy thin film is as follows:

[0041] Take a mixture of 2mmol of nickel chloride and 2mmol of cobalt chloride, put it in a beaker filled with 20ml of distilled water with 1.25ml of triethylenetetramine and stir, slowly drop into 10ml of 20mol / L sodium hydroxide solution, and add the concentration of 50% 10ml of hydrazine hydrate and 40ml of absolute ethanol were stirred to form a reaction solution. A piece of copper foil that has been cleaned by ultrasonic waves is attached to the inner wall of the reaction vessel and circles around the inner wall. Transfer the configured reaction solution into a reaction vessel, and seal the vessel. Put the container into the hollow position of the circular cylindrical magnet, transfer the reactor and the magnet together into an oven and heat to 100°C, and react for 8 hours. After the reaction, take out the film in the reaction vessel and wash it with distilled water and ethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com