Bulk emulsified base material pneumatic loading equipment for under-well medium-length hole

A technology of emulsified matrix and filling equipment, which is applied in the direction of blasting, etc., can solve the problems of waste of packaging materials, difficulty in effectively removing accumulated water, and leakage hazards, so as to reduce complexity and cost, reduce ventilation and dust removal time, and ensure safety in the construction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

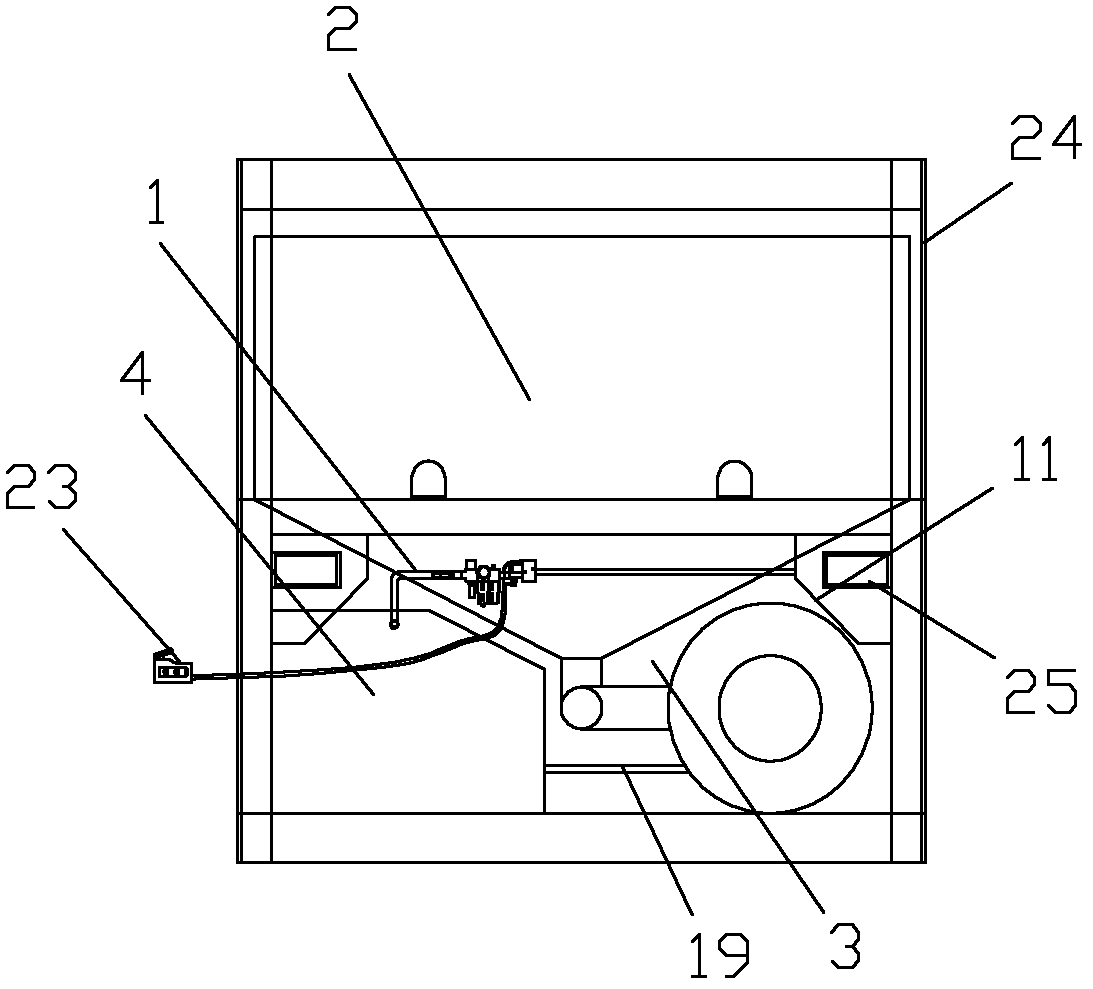

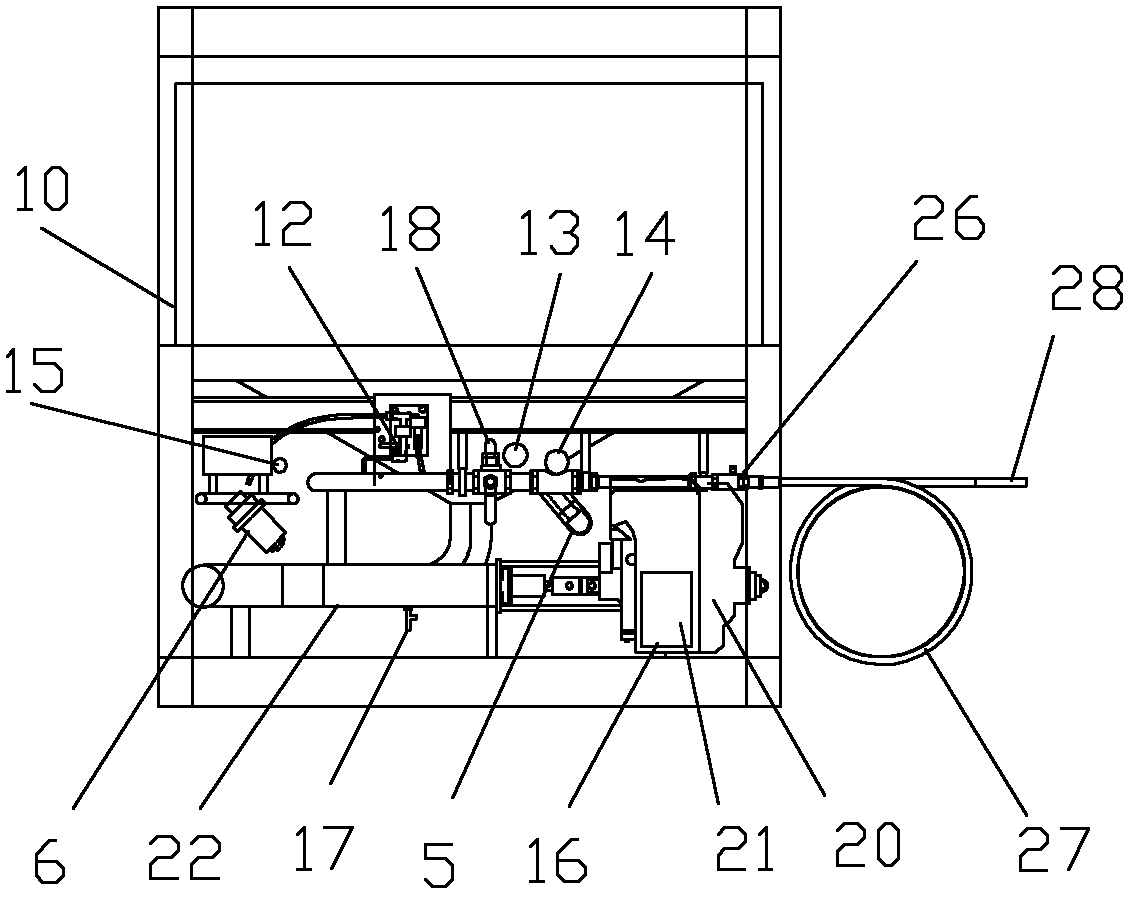

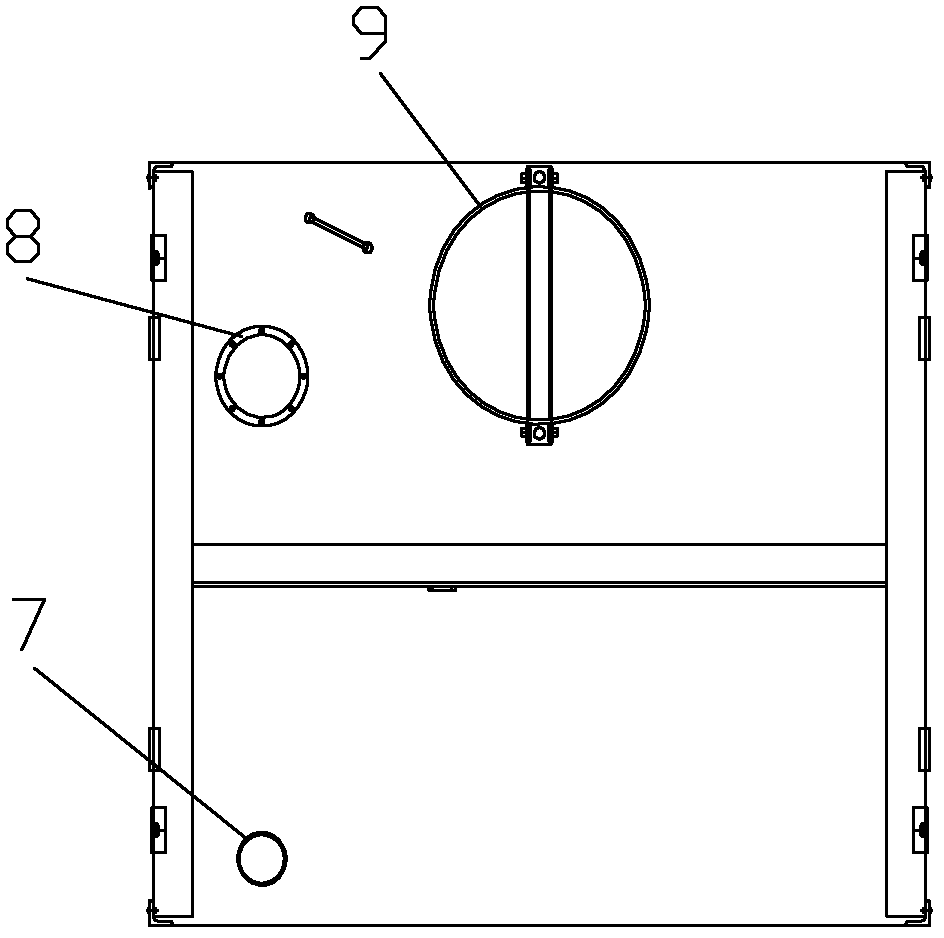

[0034] The embodiment of the present invention provides a pneumatic filling equipment for medium and deep hole bulk emulsified matrix in the well, including emulsified matrix storage and delivery device, sensitized liquid storage and delivery device and cleaning water storage and delivery device, wherein the emulsified matrix storage and delivery device includes An emulsification base container and an emulsification base filter device for storing the emulsification base, and a base pump for pumping the emulsification base, the sensitization liquid storage and delivery device includes a sensitization liquid container for storing the sensitization liquid and a sensitization liquid filtration device, As well as a sensitizing liquid pump for pumping the sensitizing liquid, the cleaning water storage and delivery device includes a cleaning water container for storing the cleaning water and a cleaning water filtering device, and an injection device for injecting the emulsified matrix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com