Temperature sensing system for rapid temperature program

A technology of temperature sensing circuit and temperature sensing, which is applied in the direction of radiation pyrometry, measuring device, electric radiation detector, etc., can solve the problems affecting the production of light absorbing layer, affecting the production quality of photovoltaic modules, and incomplete temperature data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to describe the technical characteristics of the present invention in detail, the following preferred embodiments are cited and described as follows in conjunction with the accompanying drawings, wherein:

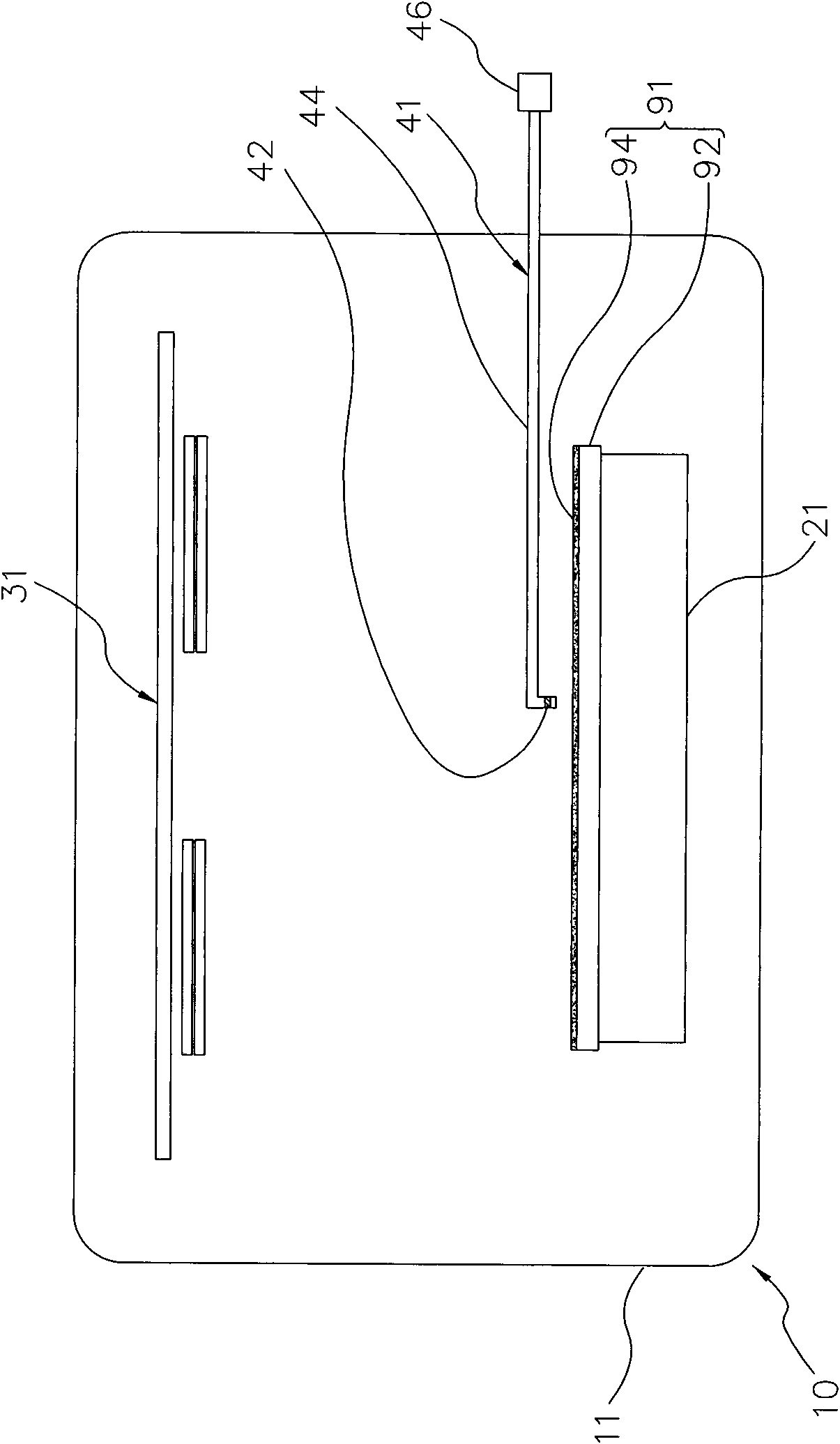

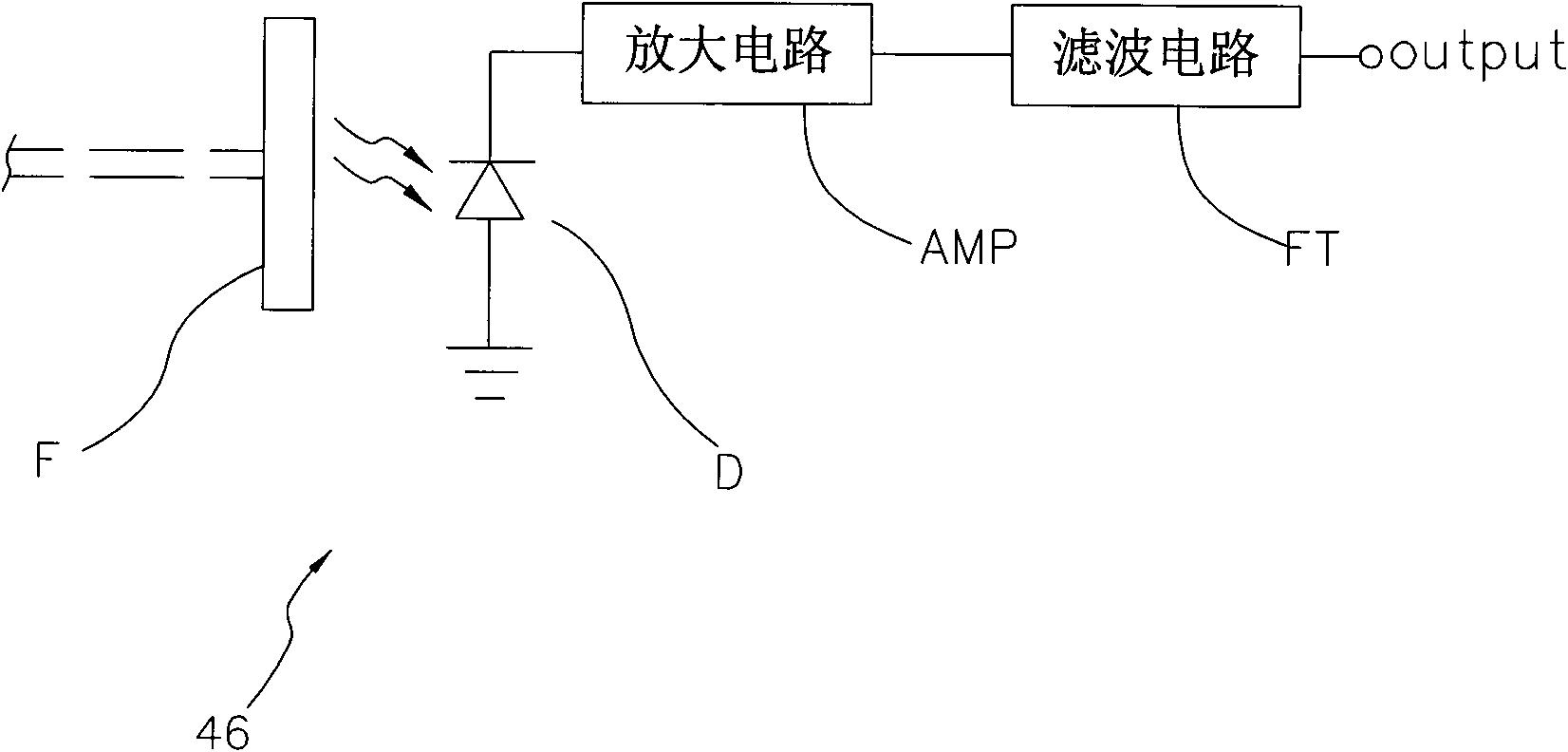

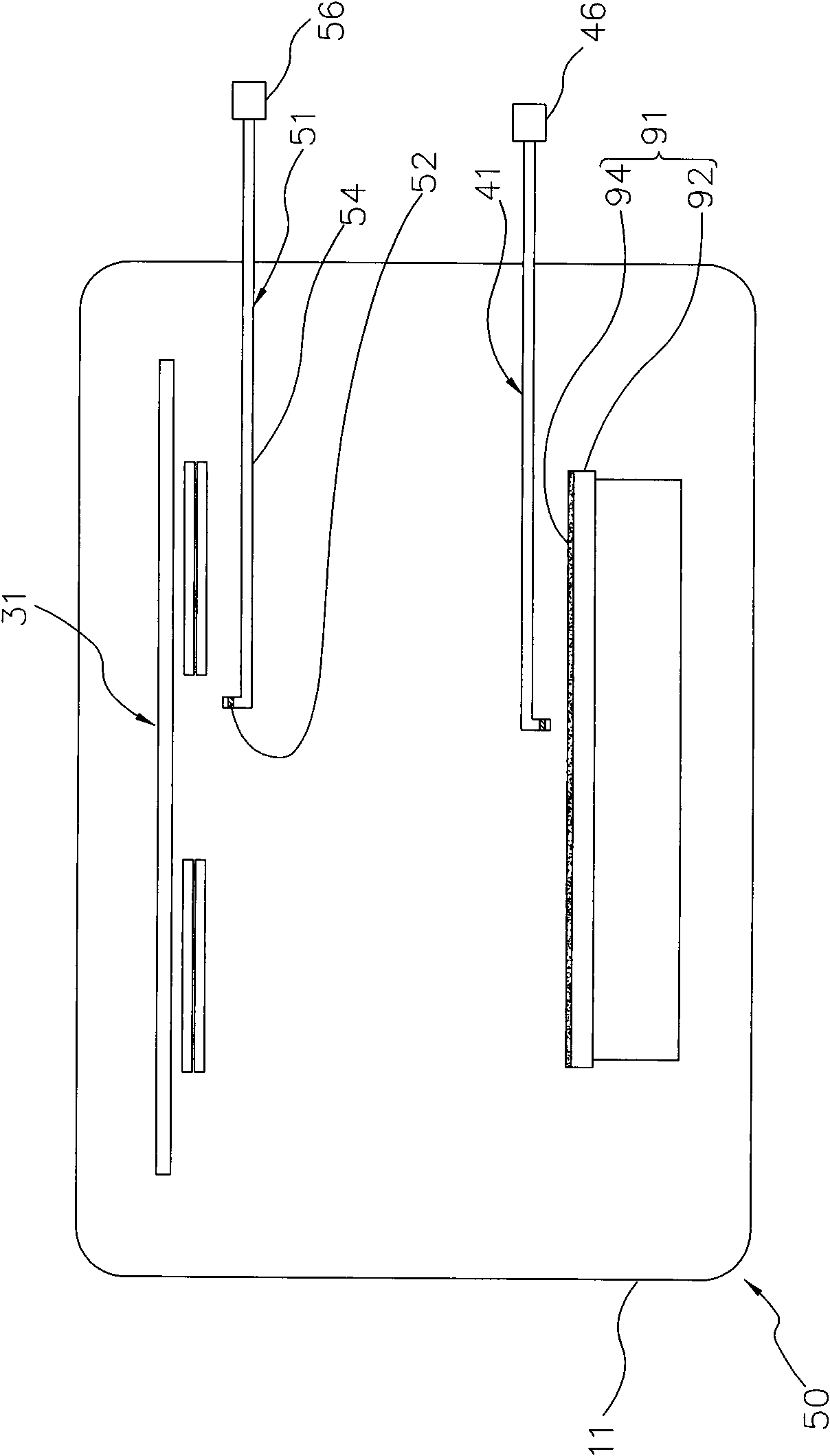

[0016] Such as Figure 1 to Figure 2 As shown, a temperature sensing system 10 used in a rapid temperature program provided by the first preferred embodiment of the present invention mainly consists of a chamber 11, a platform 21, a heat source 31 and a black body temperature detector 41 consisting of:

[0017] The rapid temperature program is used for heating a photovoltaic module intermediate product 91. In this embodiment, the photovoltaic module intermediate product 91 has a substrate 92 and at least one layer that is coated on the upper surface of the substrate 92 and is being formed. light absorbing layer 94 . In this embodiment, the substrate 92 is made of glass as an example, but it can also be an elastic metal plate, and is not limited to glass. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com