Gas hydrate sampling and analyzing method and device

A gas hydrate, sampling and analysis technology, applied in sampling devices, measuring devices, analysis materials, etc., can solve the problems of component determination, water conversion rate gas-liquid ratio gas storage and other parameters cannot be effectively characterized, sampling is difficult to uniform, The effect of the gas-liquid separator is not ideal, and the effect of accurate and reliable analysis method, true and uniform sampling, and convenient and low-cost sampling equipment is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

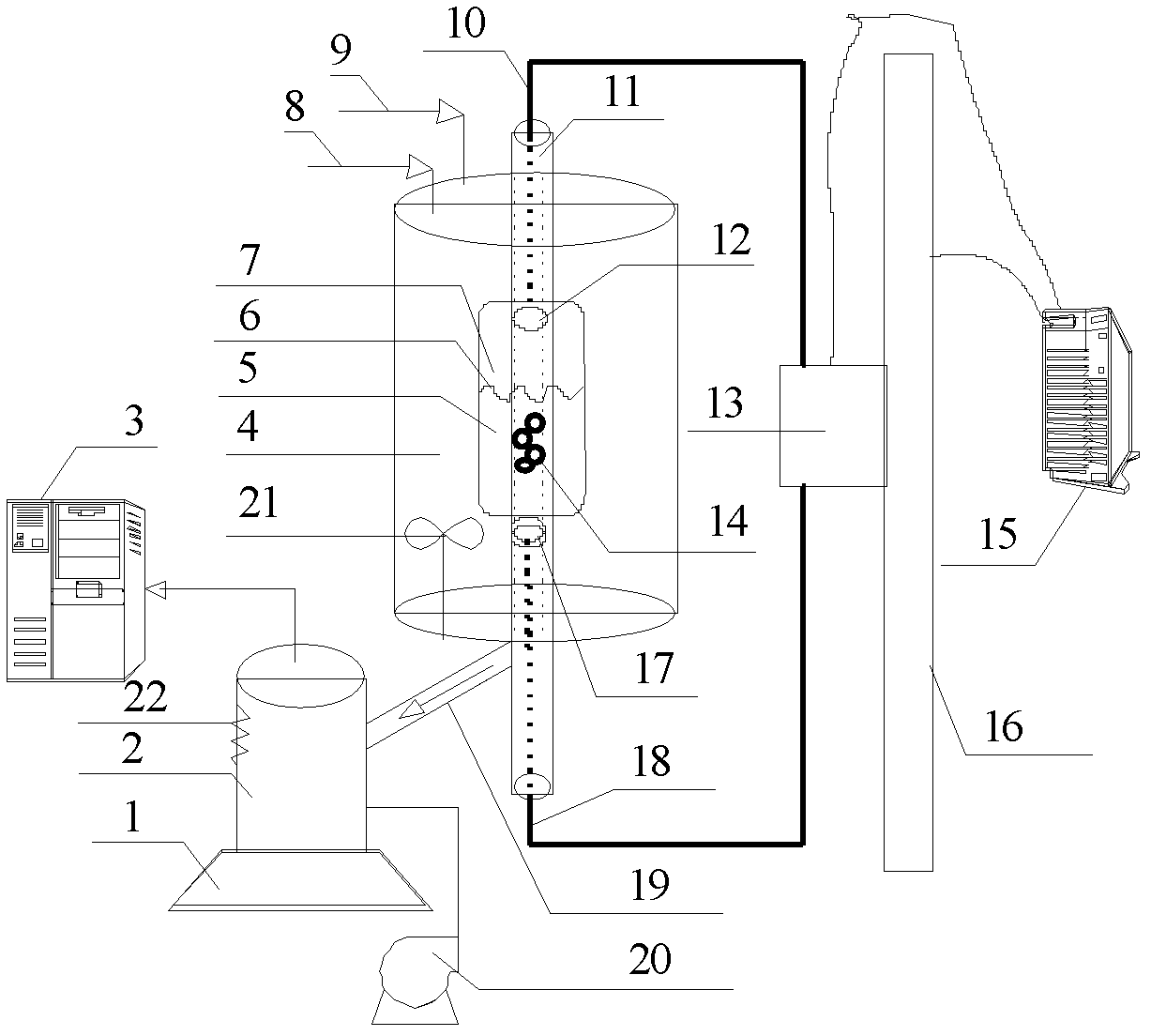

[0040] Example 1: Sampling and analysis of the solution phase of the hydrate system.

[0041] This sampling test can measure the components, solubility characteristics and solution concentration of the mixed gas in the aqueous solution. The main sampling and analysis steps are as follows:

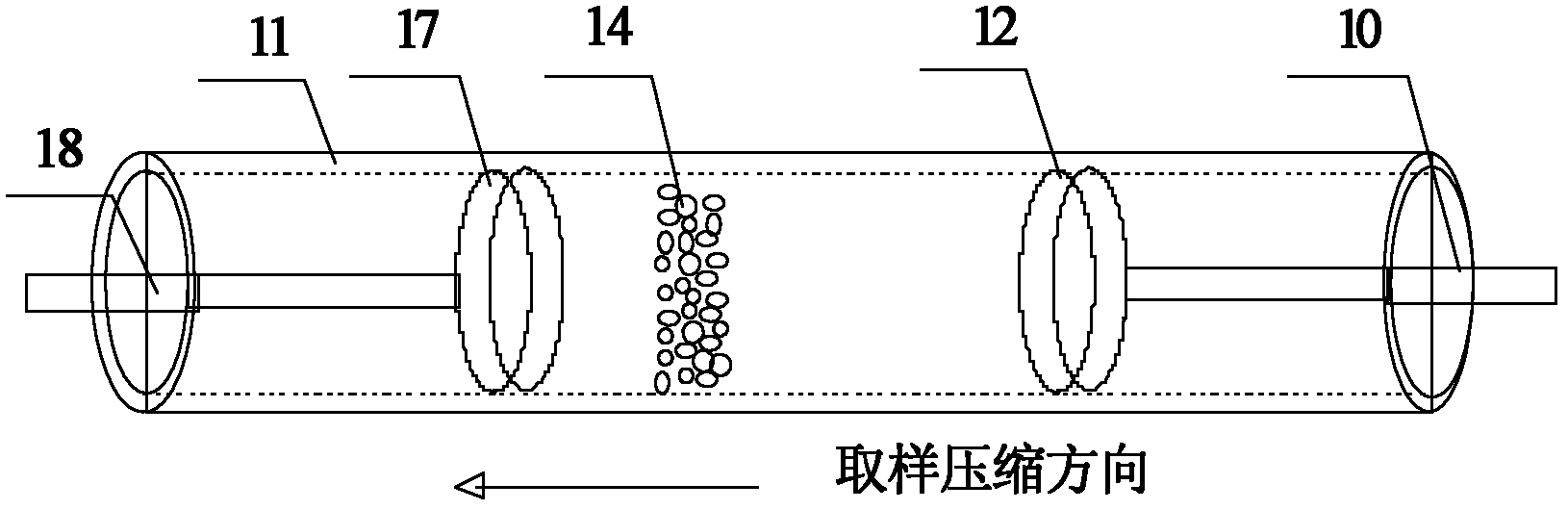

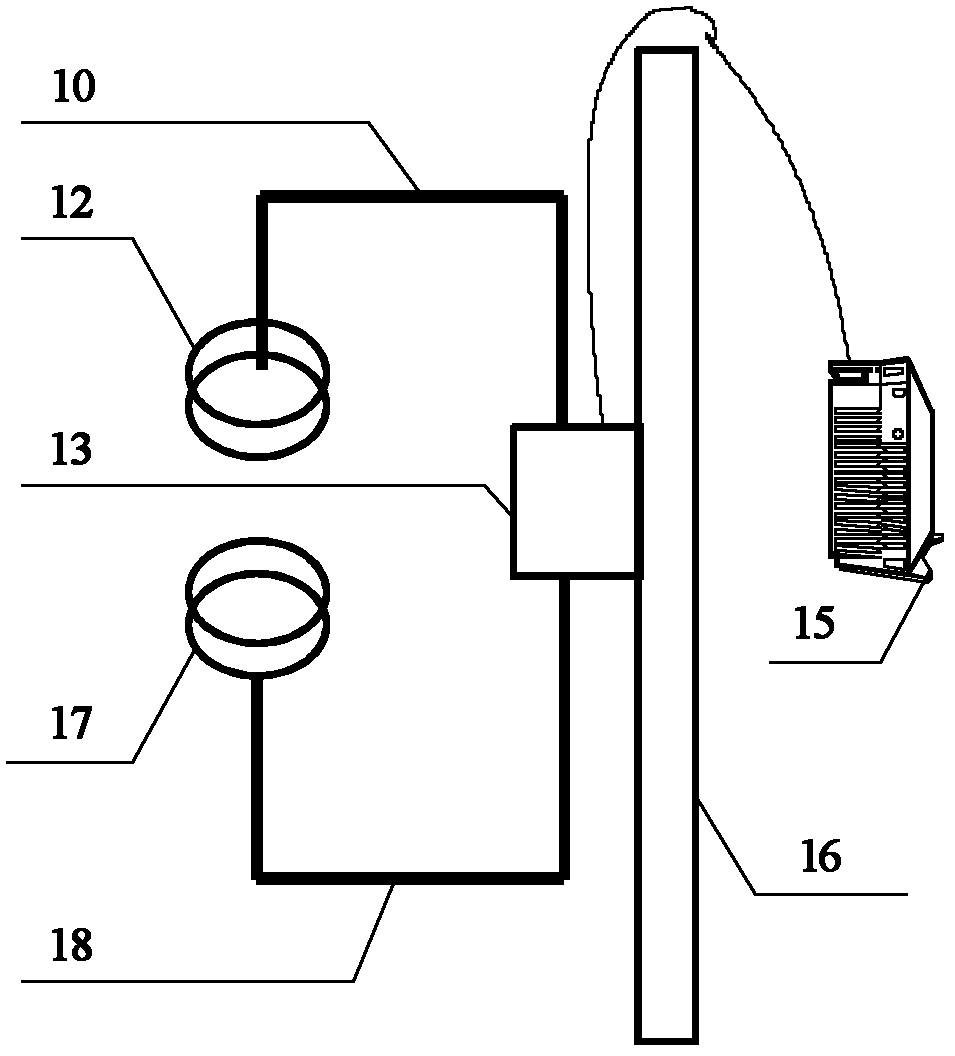

[0042] 1) First adjust the upper and lower compression pistons (12, 17) of the sampler 11 to the communication position with the sample delivery pipe 19 and the sample collection tank 2 through the screw elevator 16, use the vacuum pump 20 to vacuumize the communication system, and then pass the screw The lifter 16 adjusts the upper and lower compression pistons (12, 17) to communicate with the system in the kettle, and makes the sampling hole 14 on the pipe wall of the sampler 11 be in the solution phase 5 position.

[0043] 2) Turn on the agitator 21 so that the preset molar weight and components are respectively n G and x 0 The mixed gas (A+B) and the volume is V W The water in the h...

Embodiment 2

[0049] Example 2: Gas phase sampling and analysis test of the hydrate system.

[0050] This sampling test can directly measure the gas phase mixture composition at any time during the hydrate reaction process. The main sampling and analysis steps are as follows:

[0051] 1) First adjust the upper and lower compression pistons (12, 17) of the sampler 11 to the communication position with the sample delivery pipe 19 and the sample collection tank 2 through the screw elevator 16, use the vacuum pump 20 to vacuumize the communication system, and then pass the screw The lifter 16 adjusts the upper and lower compression pistons (12, 17) to communicate with the system in the kettle, and makes the sampling hole 14 on the pipe wall of the sampler 11 be in the gas phase 7 position.

[0052] 2) Let the preset molar weight and component be n respectively G and x 0 The mixed gas (A+B) and the volume is V W The water in the hydrate generating tank 4 is fully mixed to generate hydrate, a...

Embodiment 3

[0056] Example 3: Sampling and analysis of the hydrate slurry phase of the hydrate system.

[0057] This sampling test can directly measure the mixed gas composition of the hydrate slurry phase in the hydrate system, the consumption of gas entering the hydrate slurry phase, and the gas storage capacity of the hydrate slurry relative to the gas. The main sampling and analysis steps are as follows:

[0058] 1) First adjust the upper and lower compression pistons (12, 17) of the sampler 11 to the communication position with the sample delivery pipe 19 and the sample collection tank 2 through the screw elevator 16, use the vacuum pump 20 to vacuumize the communication system, and then pass the screw The elevator 16 adjusts the upper and lower compression pistons (12, 17) to communicate with the system in the kettle, and makes the sampling hole 14 on the pipe wall of the sampler 11 be at the hydrate slurry phase 5 position.

[0059] 2) Let the preset molar weight and component be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com