Oxidized gel for shallow layer sampling of radioactive contaminated metals and preparation method of gel

An oxidized gel and gel technology, which is applied in the field of radiation detection, can solve the problems of splashing of radioactive metal chips, inability to effectively collect shallow activated metal samples, and the rise of radioactive aerosols, etc. The effect of changing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

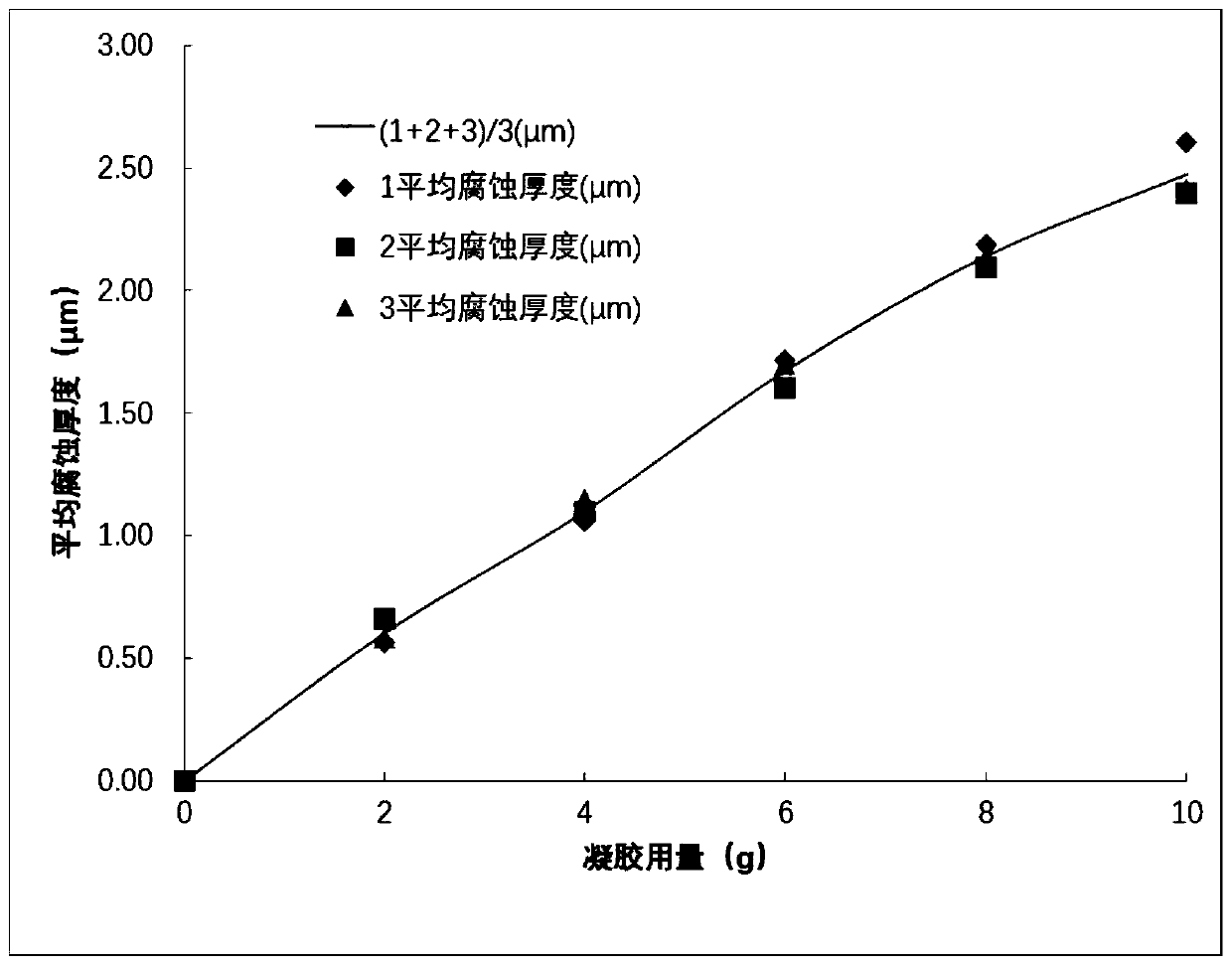

[0038] Embodiment 1: the preparation of oxidation gel and the mensuration of stainless steel sampling depth, sampling accuracy (1)

[0039] The formula composition of the oxidized gel prepared in this embodiment by weight percentage is as follows:

[0040] Gel base calcium oxide 15%, surfactant CH 3 (CH 2 ) 5 (OCH 2 CH 2 ) 2 OH is 5%, thixotropic multiplier Y1010 is 5%, strong oxidant cerium ammonium nitrate 20%, nitric acid 20%, and the balance is water (because cerium ammonium nitrate itself has bright color, slight foaming and moderate viscosity, so no need Add color indicator, defoamer and thickener).

[0041] The specific preparation method of the oxidized gel is as follows:

[0042] (1) Add the gel base material of the formula amount into the water of the formula amount, fully stir and emulsify until uniform;

[0043] (2) Add the ingredients of other formula quantities except the gel base material, water, surfactant, and thixotropic multiplier and mix evenly, and...

Embodiment 2

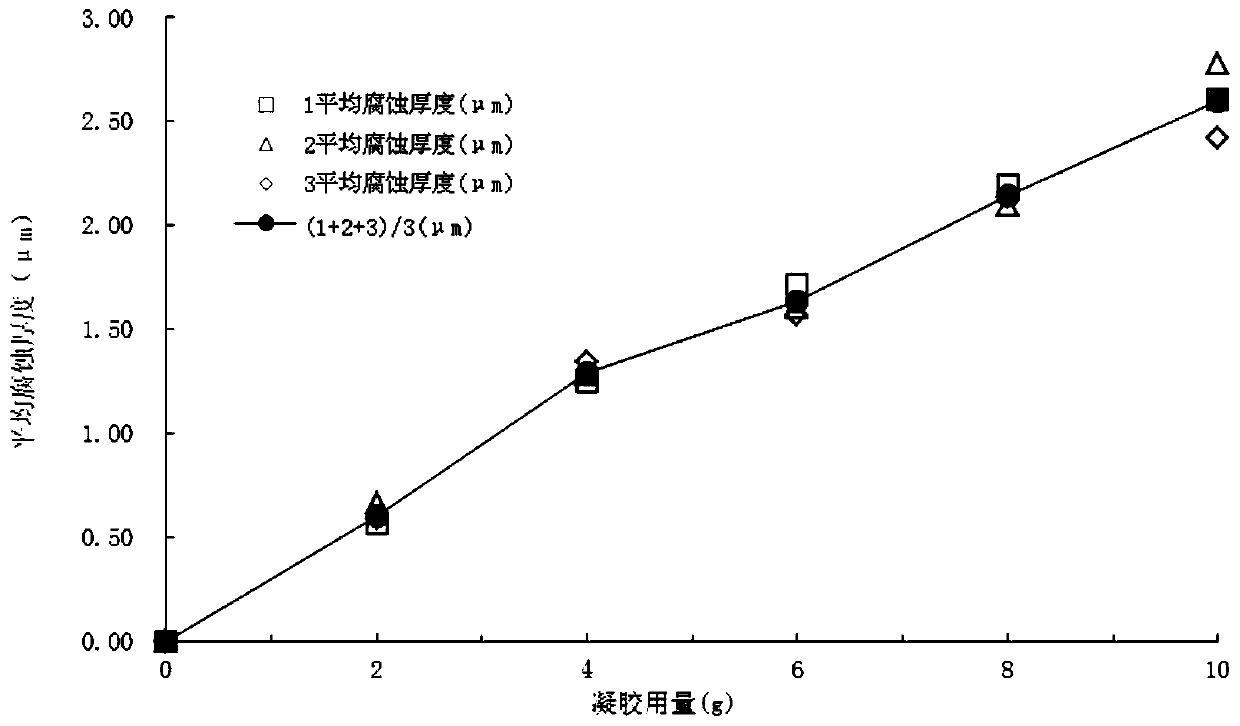

[0049] Embodiment 2: the preparation of oxidation gel and the mensuration of stainless steel sampling depth, sampling accuracy (two)

[0050] The formula composition of the oxidized gel prepared in this embodiment by weight percentage is as follows:

[0051] Gel substrate silica 5%, surfactant AT904 10%, thixotropic multiplier T2-815 0.5%, strong oxidant hexammine cobalt trichloride 3%, hydrochloric acid 3%, defoamer n-octyl 3% alcohol, 0.5% sodium dibenzylsulfonate as a color indicator, 0.1% diethylene glycol monohexyl ether as a thickener, and the balance is water.

[0052] The concrete preparation method of oxidation gel is as follows:

[0053] (1) Add the gel base material of the formula amount into the water of the formula amount, fully stir and emulsify until uniform;

[0054] (2) Add the ingredients of other formula quantities except the gel base material, water, surfactant, and thixotropic multiplier and mix evenly, and seal up for use;

[0055] (3) Before use, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com