Method for detecting and analyzing lignin content of pear pulp

An analysis method, lignin technology, applied in the field of detection and analysis of lignin content in pear pulp, can solve problems such as inappropriateness, time-consuming experiment process, errors, etc., to avoid interference, facilitate solvent dissolution, and reduce connection effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

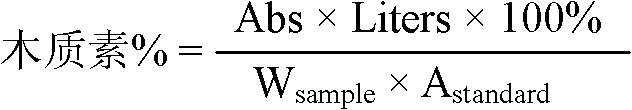

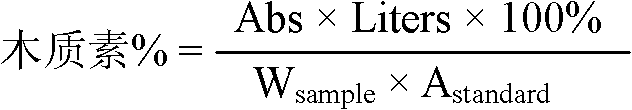

[0027] Take 10g of the middle layer of pear pulp frozen for 12 hours, 2g as a group, and divide it into 5 groups. Each group is carried out according to the following steps: Homogenize at a speed of 18000r / min for 2 minutes, dry at 60°C to constant weight, crush and over 40 mesh sieve. Weigh 0.02 g of the prepared pear pulp dry powder, wash 3 times with 95% ethanol, then rinse 3 times with alcohol:n-hexane=1:2 (V / V, volume percentage) solution, and blow dry. Put it into a 10mL test tube, add 1mL of 20% bromoacetyl-glacial acetic acid solution (w / w, mass percentage) and 0.05mL of perchloric acid with a volume concentration of 70%, put a wooden stopper on the tube mouth and seal it, and place it in a constant temperature water bath at 60°C 30min, shaking the test tube every 10min. After the reaction was finished, 3 mL of NaOH with a concentration of 2 mol / L and 2 mL of hydroxylammonium hydrochloride with a concentration of 4 mol / L were added to the test tube to terminate the re...

example 2

[0029] Take 10g of the middle layer of pear pulp frozen for 24h, 2g as a group, and divide it into 5 groups, and each group is carried out according to the following steps: Homogenize at a speed of 20000r / min for 2min, dry at 60°C to constant weight, crush and over 40 mesh sieve. Weigh 0.02 g of prepared pear pulp dry powder, wash 3 times with 95% ethanol, then rinse 3 times with alcohol:n-hexane=1:2 (V / V) solution, and blow dry. Put it into a 10mL test tube, add 2mL of 25% bromoacetyl-glacial acetic acid solution (w / w) and 0.07mL of perchloric acid with a volume concentration of 70%, put a wooden stopper on the mouth of the tube and seal it, and put it in a constant temperature water bath at 70°C for 30min. Shake the test tube every 10 min. After the reaction was finished, 3.5 mL of NaOH with a concentration of 2 mol / L and 2 mL of hydroxylammonium hydrochloride with a concentration of 4 mol / L were added to the test tube to terminate the reaction. Transfer the reaction solut...

example 3

[0031] Take 10g of the middle layer of pear pulp frozen for 18h, 2g as a group, and divide it into 5 groups, and each group is carried out according to the following steps: Homogenize at a speed of 20000r / min for 3min, dry at 60°C to constant weight, crush and over 40 mesh sieve. Weigh 0.02 g of prepared pear pulp dry powder, wash 3 times with 95% ethanol, then rinse 3 times with alcohol:n-hexane=1:2 (V / V) solution, and blow dry. Put it into a 10mL test tube, add 1mL of 30% bromoacetyl-glacial acetic acid solution (w / w) and 0.05mL of perchloric acid with a volume concentration of 70%, put a wooden stopper on the mouth of the tube and seal it, and put it in a constant temperature water bath at 80°C for 40min. Shake the test tube every 10 min. After the reaction, 4 mL of NaOH with a concentration of 2 mol / L and 3 mL of hydroxylammonium hydrochloride with a concentration of 4 mol / L were added to the test tube to terminate the reaction. Transfer the reaction solution into a 10mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com