Novel methylamino abamectin benzoate ointment and production method thereof

A technology of emamectin and benzoate ointment, which is applied in chemical instruments and methods, botanical equipment and methods, biocides, etc., and can solve the problems of long time, secondary pollution of farmland, and the amount of reaction solvent used major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

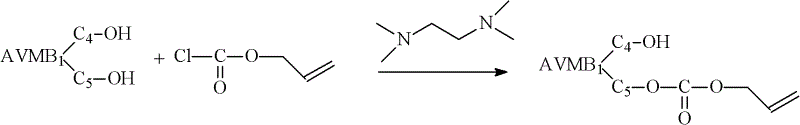

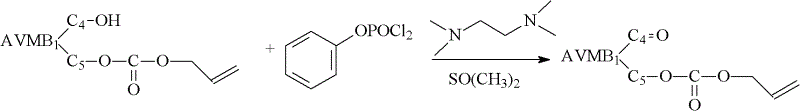

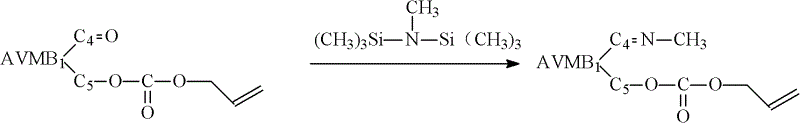

Method used

Image

Examples

Embodiment 1

[0093] An emamectin benzoate ointment,

[0094] It is characterized in that: its components are calculated by mass percentage as:

[0095] Emamectin benzoate 10-25%; antioxidant 0.1-0.3%; co-solvent 5-10%; solvent sec-butyl acetate 54.9-79.9%; other components (by-products in the reaction process) 5-10%.

Embodiment 2

[0097] According to emamectin benzoate ointment described above,

[0098] It is characterized by:

[0099] Its components are measured by mass percentage,

[0100] The better process conditions are:

[0101] Emamectin benzoate 15-20%; Antioxidant 0.2%; Cosolvent 6-8%; Solvent sec-butyl acetate 64.8-73.8%; Other components (by-products in the reaction process) 5- 7%.

Embodiment 3

[0103] According to emamectin benzoate ointment described above,

[0104] It is characterized by:

[0105] Its components are calculated by mass percentage,

[0106] The best process conditions are:

[0107] Emamectin benzoate 18%; Antioxidant 0.2%; Cosolvent is isopropanol 7.2%; Solvent sec-butyl acetate 68.6-69.6%; Other components (by-products in the reaction process) 5- 6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com