Metal non-stick pan and method for manufacturing same

A manufacturing method and technology for non-stick pans, which are used in special materials for cooking utensils, cooking utensils, household utensils, etc., can solve problems such as fragile and fragile, and achieve stable performance, good thermal conductivity, good chemical stability and cold and heat. The effect of sharp changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

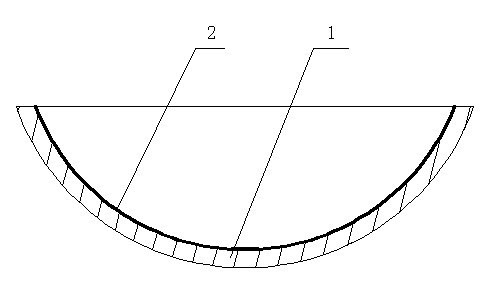

[0015] Embodiment 1: as figure 1 As shown, a metal non-stick pan includes a metal pan body 1, a metal powder sintered layer 2 is arranged on the inner surface of the pan body 1, and dense capillary pores are arranged in the metal powder sintered layer 2. Wherein, the diameter of the capillary pores ranges from 0.1 to 120.0 microns. The metal powder sintered layer 2 is pure metal powder; the particle size of all powders is ≤100 mesh; the metal powder is iron powder.

[0016] Firstly, make a metal disc with a thickness of 2 mm, press metal powder with a thickness of 1 to 3 mm on the metal disc, and put the pressed billet into a high-temperature furnace for sintering. Minutes, through physical and chemical processes such as diffusion, welding, compounding, dissolution, and recrystallization between particles, between particles and metal plates, the fusion and welding between particle powders, particle powders and metal plates form a whole, that is A metal powder sintered layer ...

Embodiment 2

[0018] Embodiment 2: basically the same as Embodiment 1, the difference is: the metal powder sintered layer 2 is a mixture of metal powder and non-metal powder, its weight ratio is 95:5, the metal powder is iron; the non-metal powder The powder is alumina.

[0019] When making, first make a metal disc, press a mixture of metal powder and non-metal powder with a thickness of 1 to 3mm on the metal disc, put the pressed blank into a high-temperature furnace for sintering, and the sintering temperature is 80% lower than the melting point of the metal powder. ℃, sintering for 5-10 minutes, and obtain a metal powder sintered layer 2 with dense capillary pores on the metal disc; then stamp the metal disc into pots of different shapes to obtain the metal non-stick pan.

Embodiment 3

[0020] Embodiment 3: basically the same as Embodiment 2, the difference is: the metal powder sintered layer 2 is a mixture of metal powder and non-metal powder, and its weight ratio is 85:15, the metal powder is copper; the non-metal powder The powder is silicon oxide.

[0021] First, make a metal disc, press a mixture of metal powder and non-metal powder with a thickness of 1 to 3 mm on the metal disc, put the pressed billet into a high-temperature furnace for sintering, and the sintering temperature is 50°C lower than the melting point of the metal powder. After 5-10 minutes, a metal powder sintered layer 2 with dense capillary pores is obtained on the metal circular plate; then the metal circular plate is punched and formed into pots of different shapes to obtain the metal non-stick pan. Finally, the metal non-stick pan is steamed for 1-3 hours with steam at 600° C. after stamping to improve the antirust ability of the pan body 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com