Comprehensive recycling method and device for high-salt-content amino acid waste water

A technology for recovery and treatment of amino acids, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as inability to perform heat exchange, large investment in equipment, uneconomical and applicable, etc. Achieve the effect of reduced system operation cost, low processing cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

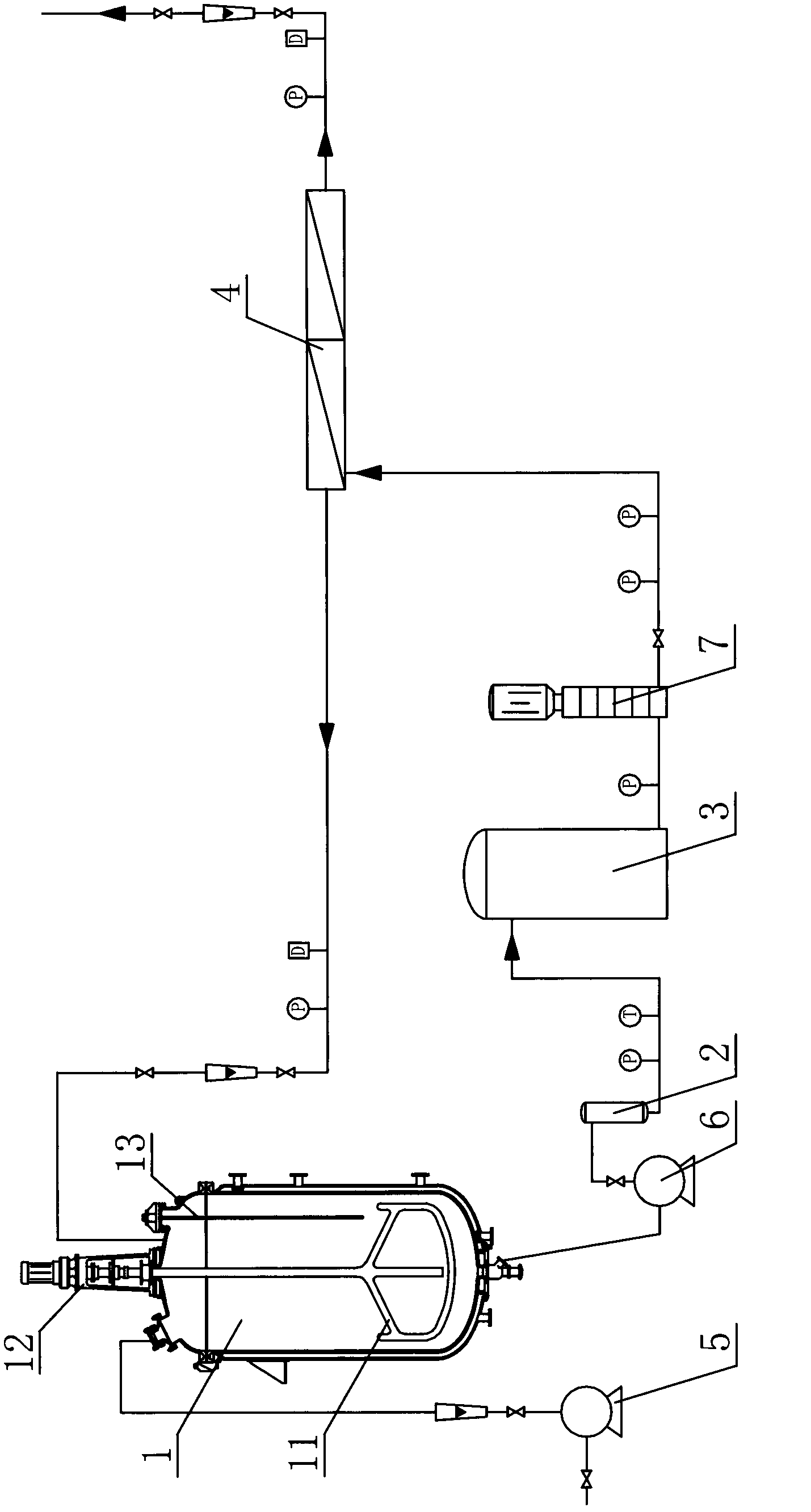

[0042] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

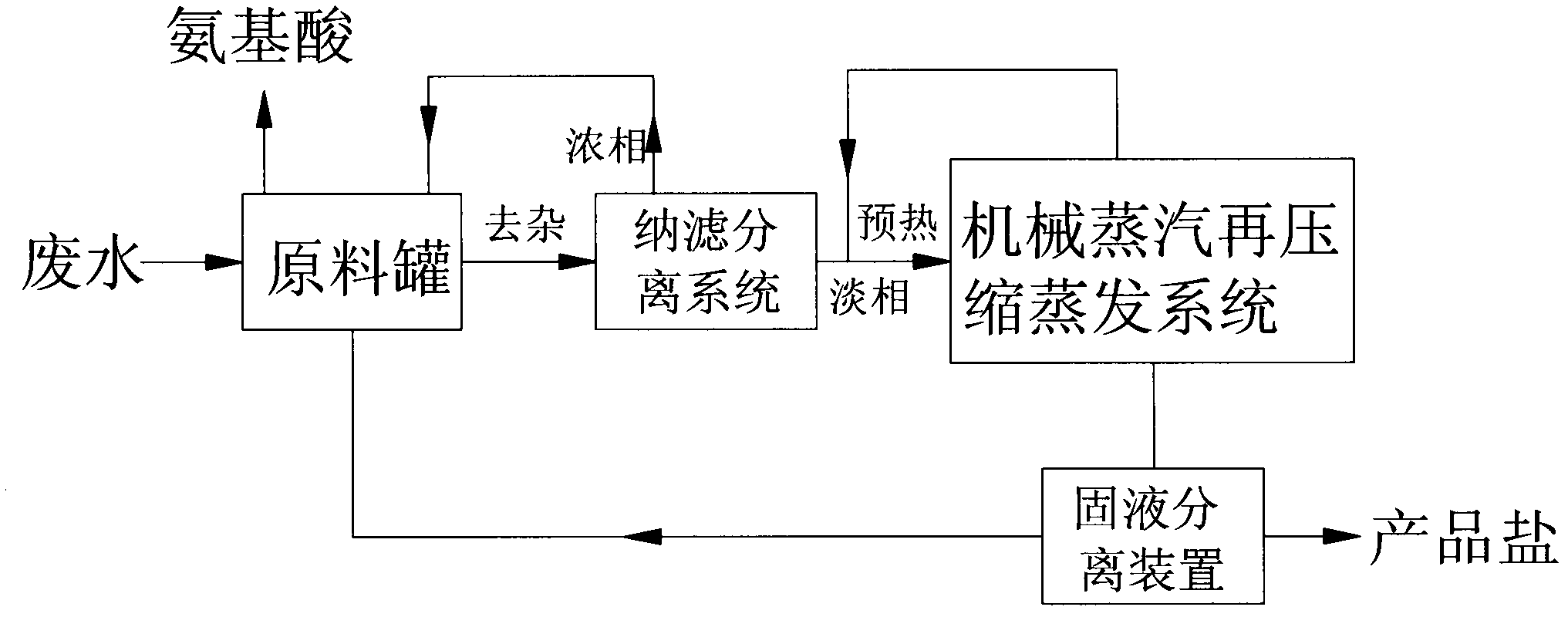

[0043] The comprehensive recovery and treatment method of high salinity amino acid wastewater of the present invention has the following steps:

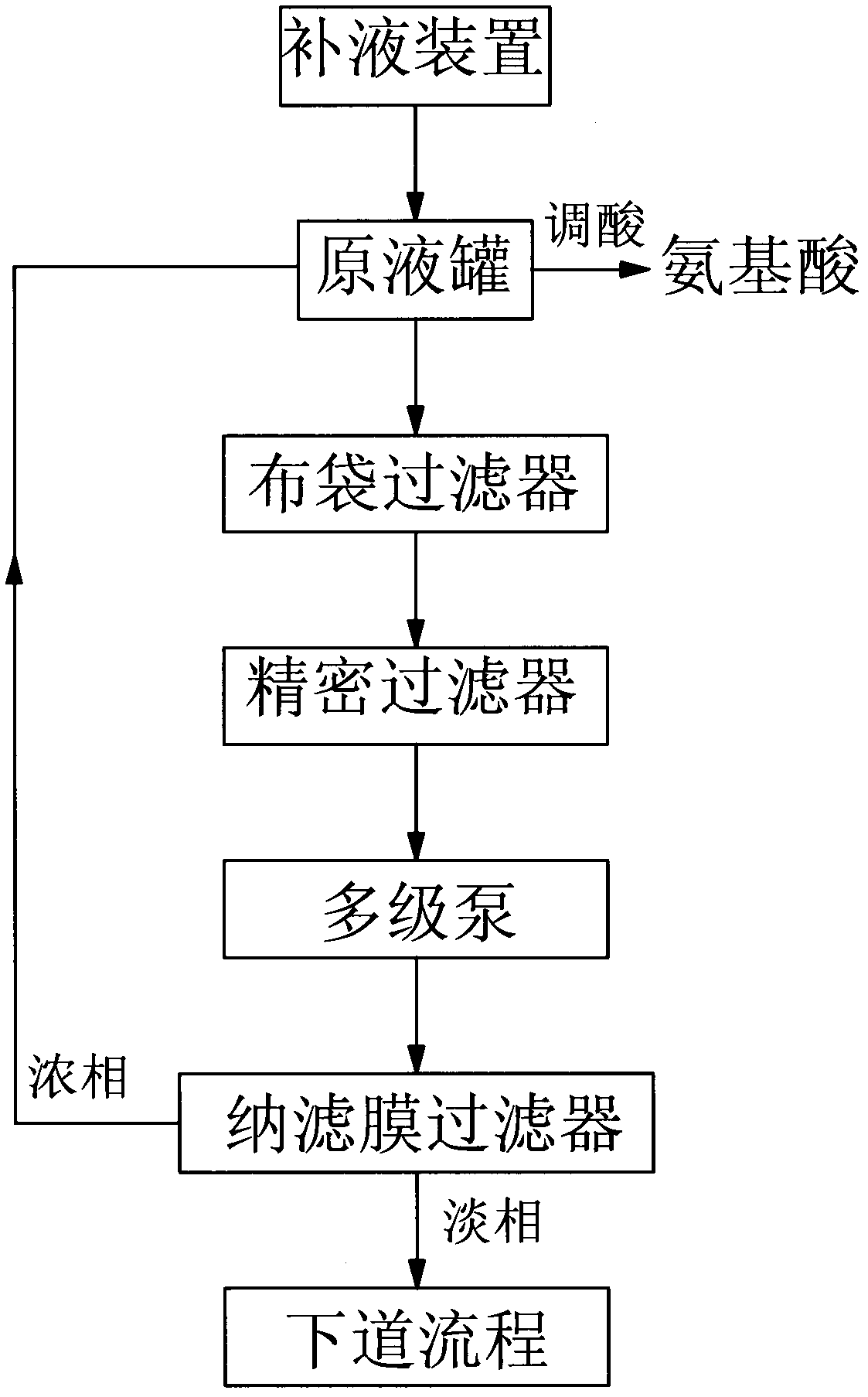

[0044] ① Removal of impurities: Remove particles with a particle size of more than 1 micron in the salty organic wastewater of the aspartame industry through a filter;

[0045] ②Separation of organic matter and inorganic matter: 8-inch nanofiltration membrane is used, the flux of a single membrane is 8-12 cubic meters per hour, the pressure is 2-4MPa, the temperature is 20-50°C, and the aspartame industry that has removed particulate impurities is filtered For saline organic wastewater, collect dense phase wastewate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com