Device for treating wastewater produced in production process of alkaline peroxide mechanical pulp (APMP)

A treatment device and technology for pulping wastewater, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. problems, to prevent sludge bulking, reduce load, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

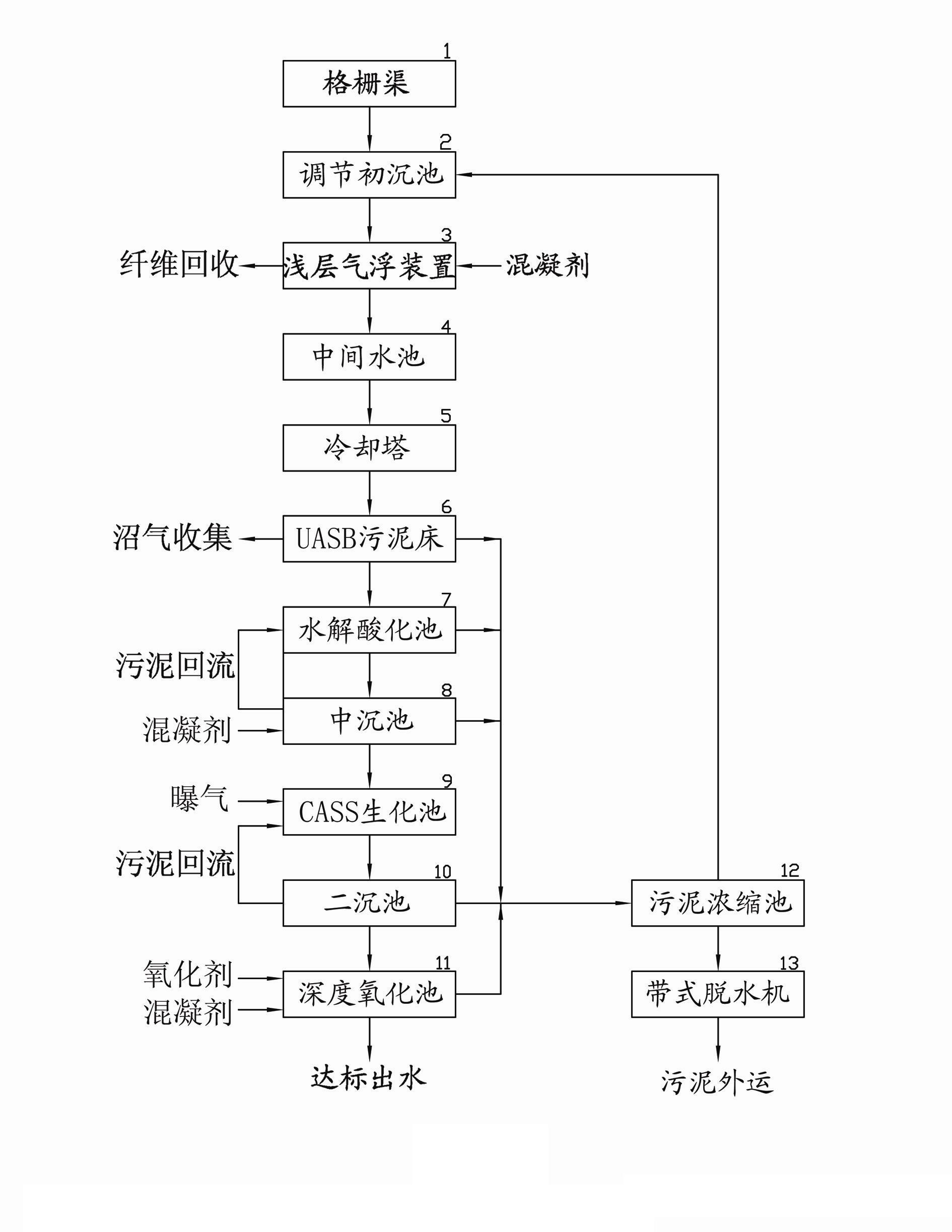

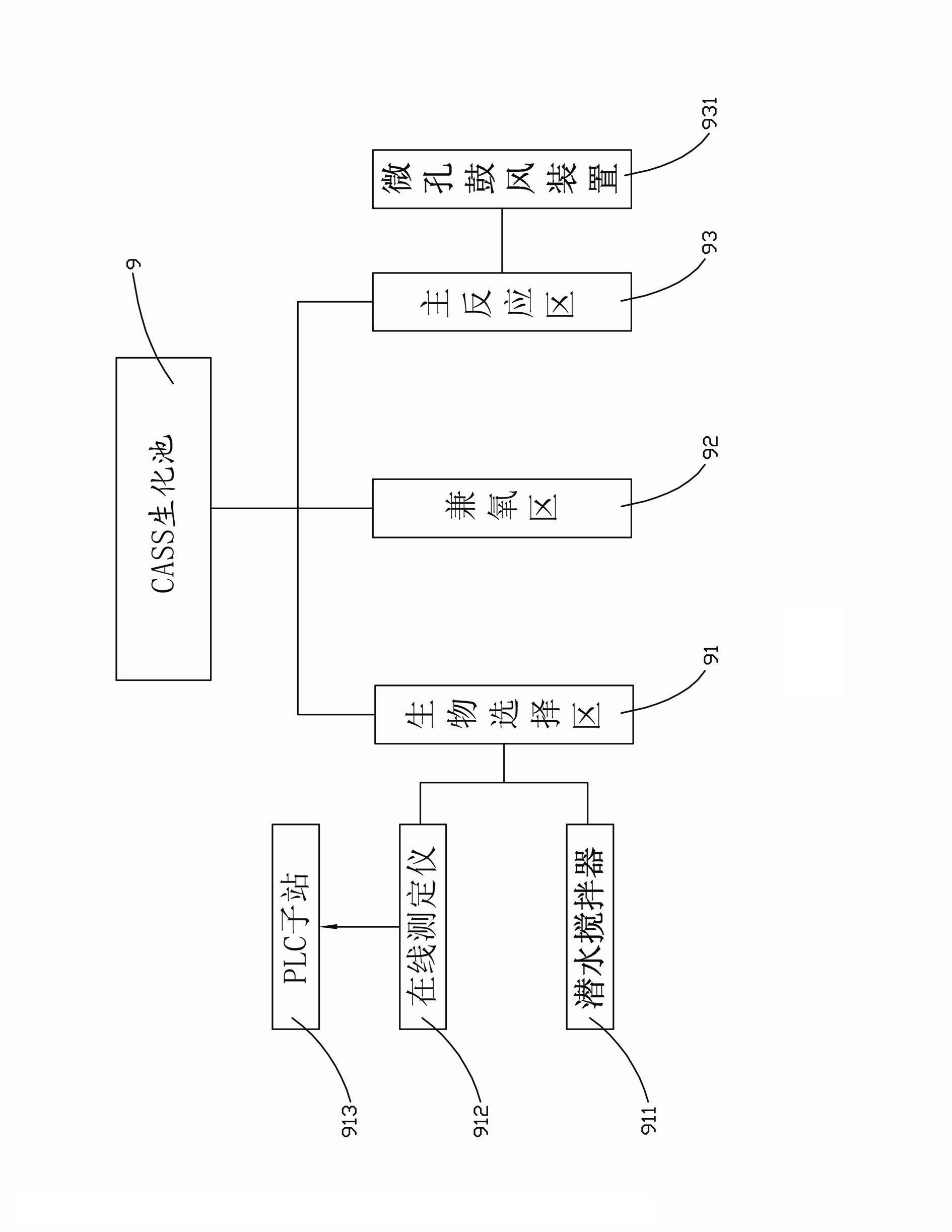

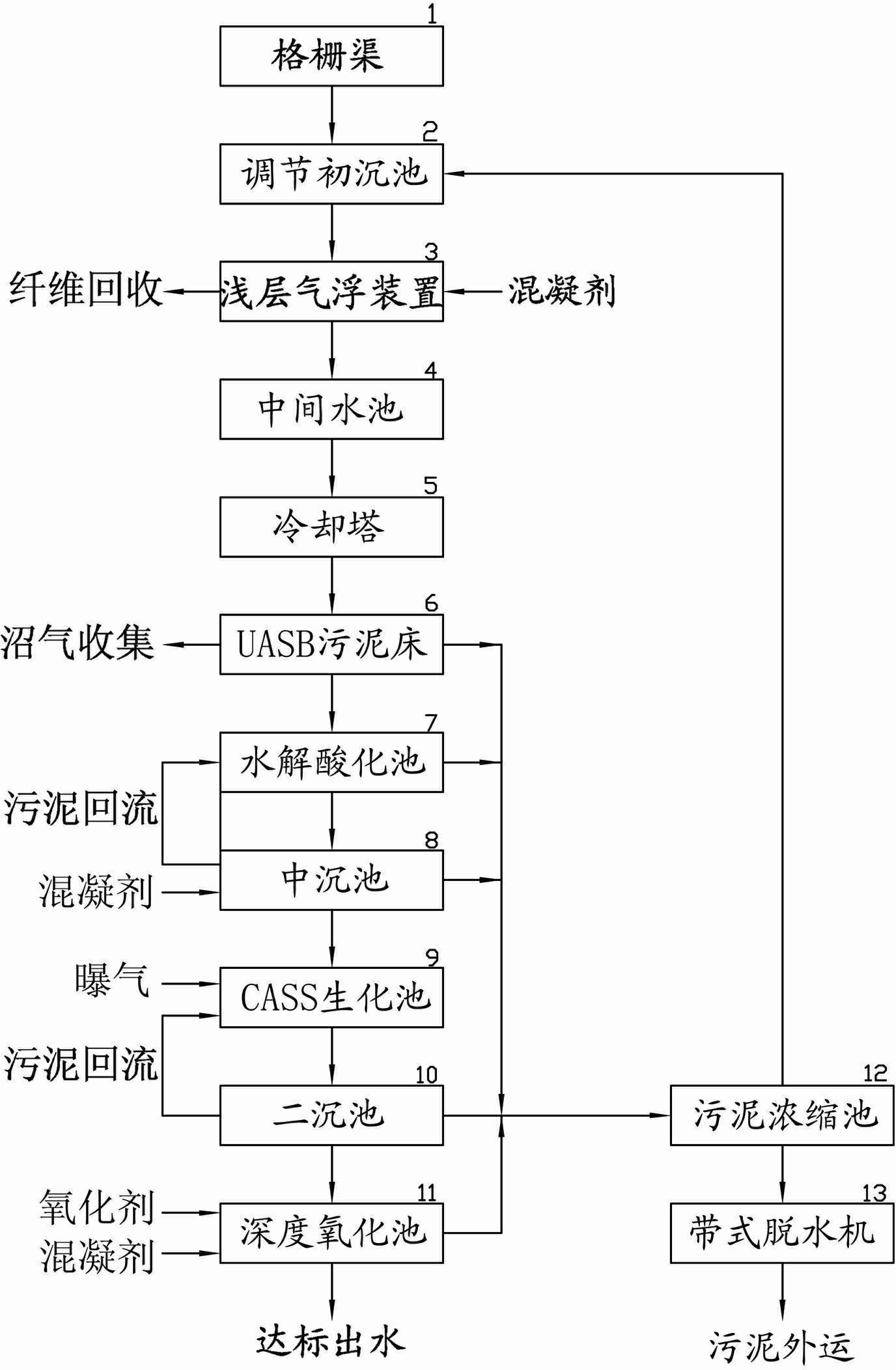

[0022] refer to figure 1 , a treatment device for APMP pulping wastewater consists of a grid channel 1 connected in sequence, a regulating primary sedimentation tank 2, a shallow air flotation device 3, an intermediate pool 4, a cooling tower 5, a UASB sludge bed 6, and a hydrolysis acidification tank 7. It is composed of intermediate sedimentation tank 8, CASS biochemical tank 9, secondary sedimentation tank 10 and deep oxidation tank 11. The secondary sedimentation tank 8 is connected with a sludge concentration tank 12, and the sludge concentration tank 12 is connected to a belt dehydrator 13.

[0023] The chemical-mechanical pulp wastewater flows into the grid tank 1 through the sewage pipes, and after the grid decontamination machine removes fibers and a large amount of suspended matter, it enters the adjustment primary sedimentation tank 2 to adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com