Method for recovering N-acetyl-DL-methionine and by-products of sodium acetate trihydrate from N-acetyl-DL-methionine racemization waste liquid

A technology of methionine and sodium acetate, applied in chemical instruments and methods, preparation of carboxylate, preparation of organic compounds, etc., can solve problems such as low yield of N-acetyl-DL-methionine crystallization, energy waste, etc., and achieve environmental protection The effect of friendliness, high recovery rate and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

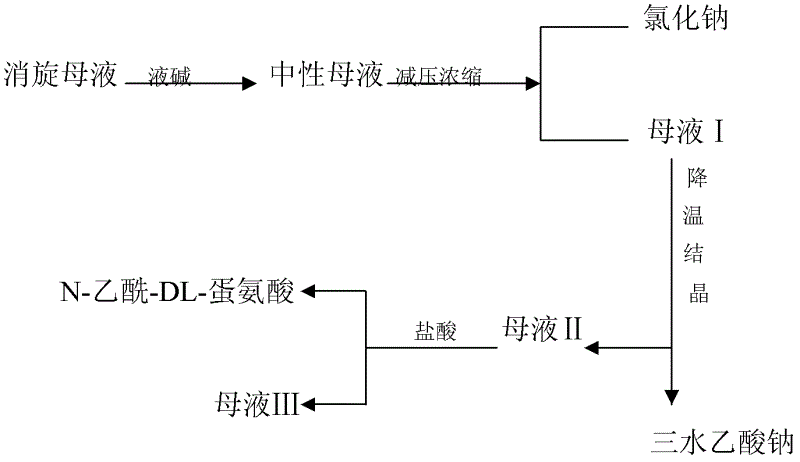

[0017] Take 1200L of racemized waste liquid (containing 3500mol of chloride ions, 6000mol of acetate ions, and 176kg of N-acetyl-DL-methionine), adjust the pH to 3 with 30% NaOH, and concentrate under reduced pressure to 1 / 4 of the original volume. Control at 20-25°C, precipitate 180kg of sodium chloride, cool the remaining mother liquor to 0-2°C, obtain 350kg of by-product sodium acetate trihydrate, add 30% HCL to the remaining mother liquor to adjust the pH to 1, and cool down to 5-7°C, Crystals were precipitated to obtain 96 kg of N-acetyl-DL-methionine.

Embodiment 2

[0019] Take 1200L of racemized waste liquid (containing 3500mol of chloride ions, 6000mol of acetate ions, and 176kg of N-acetyl-DL-methionine), adjust the pH to 3 with 30% NaOH, and concentrate under reduced pressure to 1 / 4 of the original volume. Control at 30-35°C, precipitate 180kg of sodium chloride, cool the remaining mother liquor to 0-2°C, obtain 350kg of by-product sodium acetate trihydrate, add 30% HCL to the remaining mother liquor to adjust the pH to 1, and cool down to 5-7°C, Crystals were precipitated to obtain 90 kg of N-acetyl-DL-methionine.

Embodiment 3

[0021] 800L racemic waste liquid (its composition is 2660mol of chloride ion, 6590mol of acetate ion, 96kg of N-acetyl-DL-methionine), adjust pH to 6 with 30% NaOH, concentrate under reduced pressure to 2 / 5 of the original volume, temperature Controlled at 60-65°C, precipitated 135kg of sodium chloride, cooled the remaining mother liquor to 10-12°C, obtained 381kg of by-product sodium acetate trihydrate, added 30% HCL to the remaining mother liquor to adjust the pH to 2, and lowered the temperature to 5-7°C. Crystals were precipitated to obtain 64 kg of N-acetyl-DL-methionine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com