Preparation process of high-purity oxymatrine

A technology of oxymatrine and preparation process, applied in the direction of organic chemistry and the like, can solve the problems of lack of practicability, the purity cannot reach more than 99%, etc., and achieve the effects of low cost, high product purity and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

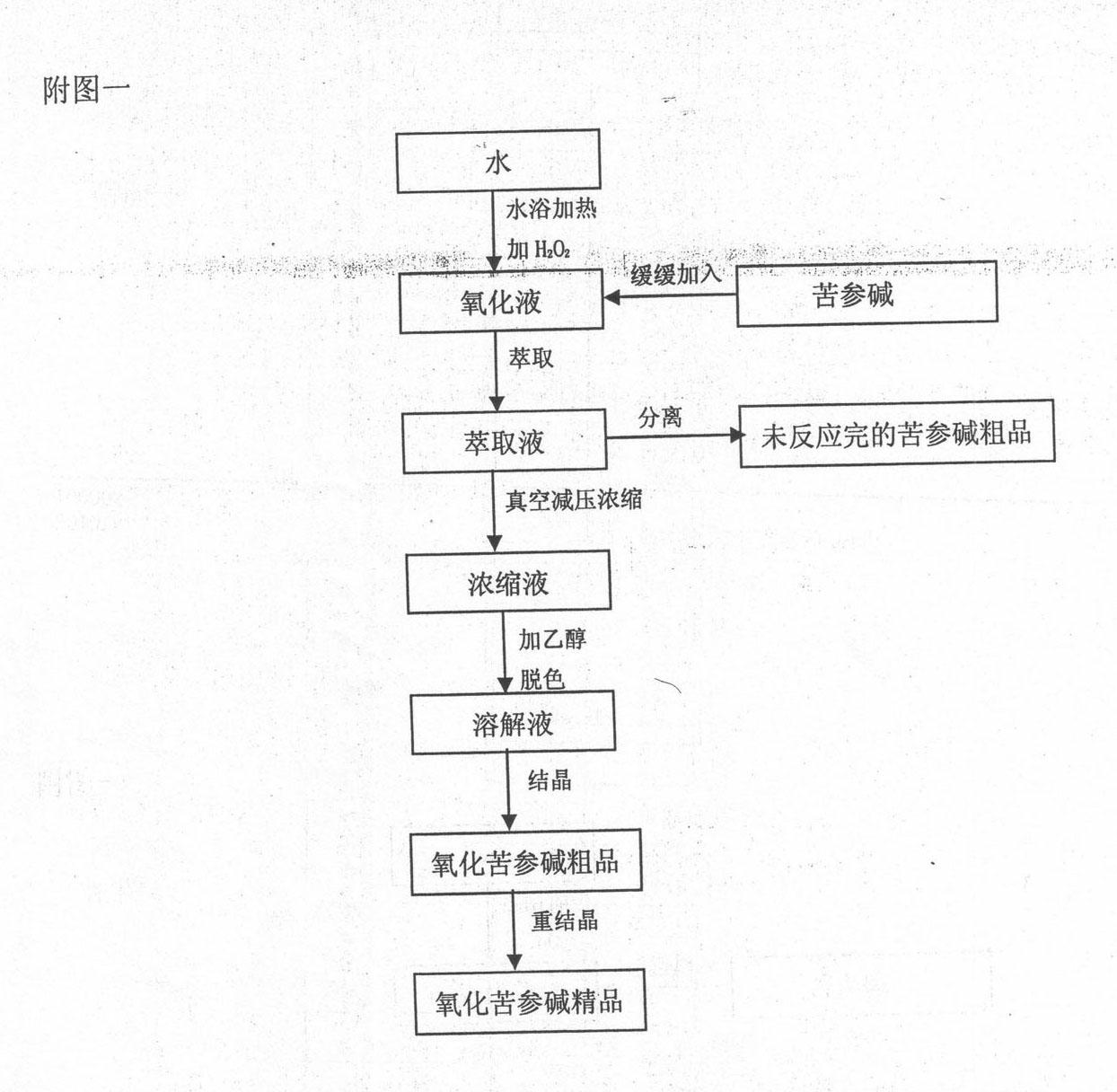

Image

Examples

Embodiment 1

[0027] Add water to the oxidation tank and heat it up to 75°C, add 51g of analytically pure hydrogen peroxide, slowly add 100g of crude matrine in crystallized water, and react at 61°C for 13 hours, extract unreacted matrine with toluene until it reaches the reaction solution. Basically no matrine, concentrate under vacuum and decompression, recover water to dryness; add ethanol to dissolve, add aluminum oxide (Al 2 o 3 ) 30g for decolorization, suction filtration; vacuum concentration again, recovery of ethanol to dryness, adding acetone to melt, cooling and crystallization, centrifugation to obtain 101g of crude oxymatrine, the crude product of oxymatrine was dissolved in ethanol, and the ethanol solution was passed through The decolorizing agent is decolorized, the decolorized solution is suction-filtered, the ethanol is recovered, acetone is added to stir, cooling and crystallization is carried out, and 95 g of fine oxymatrine is obtained by centrifugation, and the content...

Embodiment 2

[0029] Add water to the oxidation tank and heat it to 75°C, add 51g of analytically pure hydrogen peroxide, slowly add 100g of crude matrine in crystallized water, and react at 59°C for 12 hours, extract the unreacted matrine with benzene until it is in the reaction solution There is basically no matrine, concentrated under reduced pressure in vacuum, and recovered water to dryness. Add ethanol to dissolve, add aluminum oxide (Al 2 o 3 ) 30g for decolorization, suction filtration; vacuum concentration again, recovery of ethanol to dryness, adding acetone to melt, cooling and crystallization, centrifugation to obtain 97g of crude oxymatrine, the crude oxymatrine was dissolved in ethanol, and the ethanol solution was passed through The decolorizing agent is decolorized, the decolorized solution is suction-filtered, the ethanol is recovered, acetone is added to stir, cooling and crystallization is carried out, and 92.8 g of fine oxymatrine is obtained by centrifugation, and the ...

Embodiment 3

[0031] Add water to the oxidation tank and heat it to 75°C, add 51g of analytically pure hydrogen peroxide, slowly add 100g of crude matrine in crystallized water, and react at 62°C for 12 hours, then extract the unreacted matrine with toluene until it reaches the reaction solution. There is basically no matrine, concentrated under reduced pressure in vacuum, and recovered water to dryness. Add ethanol to dissolve, add aluminum oxide (Al 2 o 3 ) 30g for decolorization, suction filtration; vacuum concentration again, recovery of ethanol to dryness, adding acetone for hot melting, cooling and crystallization, centrifugation to obtain 101g of crude oxymatrine, adding ethanol to dissolve the crude oxymatrine, and ethanol solution through The decolorizing agent is used for decolorizing, the decolorizing solution is suction-filtered, the ethanol is recovered, acetone is added to stir, cooling and crystallization is carried out, and 95.6 g of fine oxymatrine is obtained by centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com