Preparation method of biapenem aseptic powder

A technology of biapenem and sterile powder, applied in the field of preparation of biapenem and its sterile powder, can solve the problems of poor solubility, increase in substance, prolong operation time and the like, achieve easy quality control and increase stability , the effect of increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

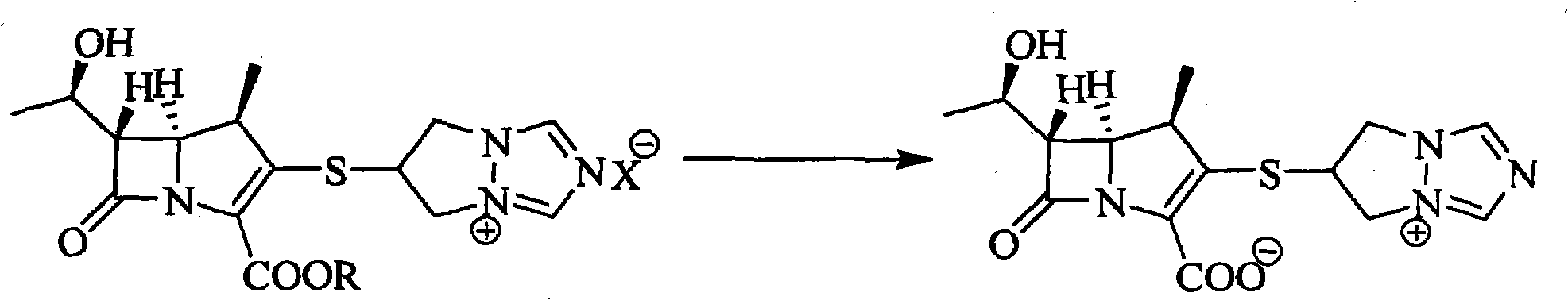

Image

Examples

Embodiment 1

[0044] Example 1 Preparation of Biapenem Aseptic Powder

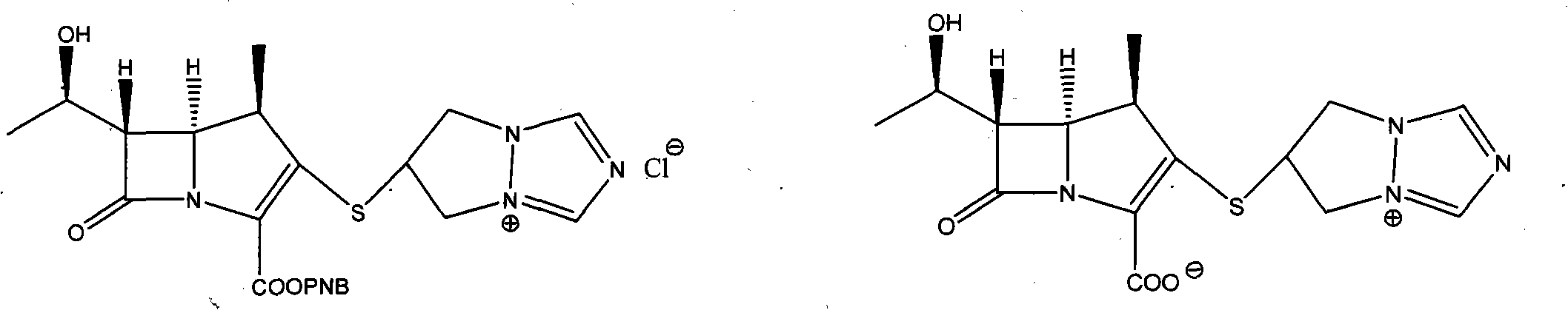

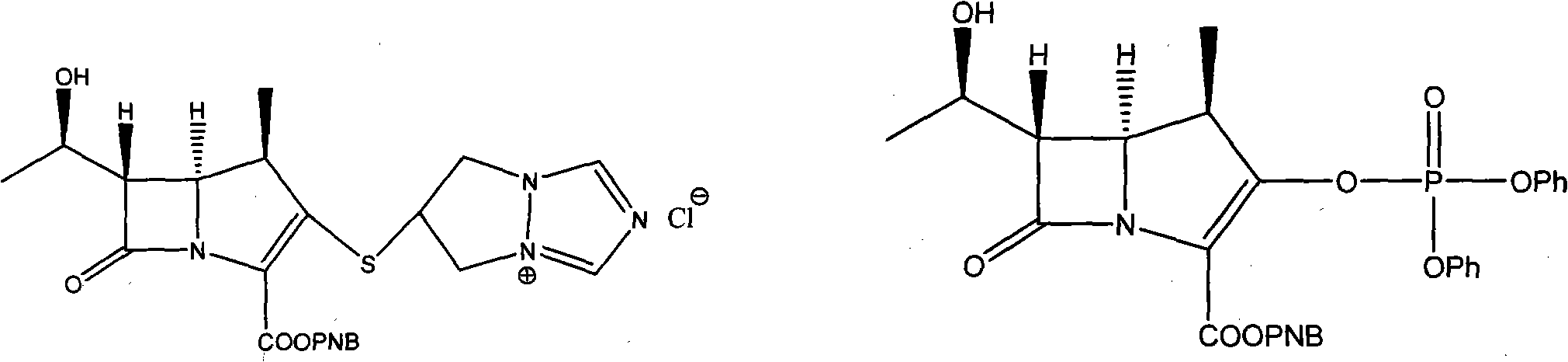

[0045] 1.16-[(4R,5S,6S)-6-[(1R)-1-Hydroxyethyl]-4-methyl-2-p-nitrobenzyloxycarbonyl-7-oxo-1-azabicyclo [3.2.0] Hept-2-en-3-yl]thio-6,7-dihydro-5H-pyrazolo[1,2-a][1,2,4]-triazole-4- Synthesis of Onium Chloride(II)

[0046] In the reaction kettle, add 104Kg of acetonitrile, 16.5Kg of compound of formula III (MAP) and 5.9Kg of compound of formula IV, stir, the mixture is cooled to 0-5°C, and 5.3Kg of diisopropylethylamine is added dropwise thereto. Keeping the temperature at 0-5° C. to continue the reaction for about 3.5 hours, the precipitated solid in the reaction solution was filtered off and dried to obtain 14 Kg of the compound of formula II in the form of light yellow solid, yield: 94%.

[0047] m.p. = 162.0-163.6°C (decomposition).

[0048] 1.2 Synthesis of crude biapenem

[0049] Heat 75Kg of water for injection to 30-35°C, add 5Kg of the compound of formula II, add 25L of tetrahydrofuran under stirring, and st...

Embodiment 2

[0056] Example 2 Preparation of Biapenem Aseptic Powder

[0057] In the aseptic workshop, first heat 125Kg of water for injection adjusted to pH = 4.5 with acetic acid to 60°C, then add 6.25Kg of crude biapenem, stir to dissolve, if it is not clear, add water for injection until clear, add activated carbon to keep warm After 15 minutes, filter out the active carbon, filter the filtrate with a 0.22 μm microporous membrane, check the clarity of the filtrate, and add ethanol that is 2 times the volume of water for injection after passing through a 0.22 μm microporous membrane to pass the clarity. Cool to -10-5°C, stir and crystallize for 2-3 hours, filter, and dry under reduced pressure at 40°C to obtain 5.3Kg of biapenem sterile powder with a yield of 84.8%.

Embodiment 3

[0058] Example 3 Preparation of Biapenem Aseptic Powder

[0059] In the aseptic workshop, first heat 125Kg of water for injection adjusted to pH = 4 with acetic acid to 40°C, then add 6.25Kg of crude biapenem, stir to dissolve, if it is not clear, add water for injection until clear, add activated carbon to keep warm After 15 minutes, filter out the active carbon, filter the filtrate with a 0.22 μm microporous membrane, check the clarity of the filtrate, and add ethanol that is 2 times the volume of water for injection after passing through a 0.22 μm microporous membrane to pass the clarity. Cool to -10-5°C, stir and crystallize for 2-3 hours, filter, and dry under reduced pressure at 40°C to obtain 5.09Kg of biapenem sterile powder with a yield of 81.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com