Polyacrylic ester and polyacrylic ester copolymer material hydrophilic modification products and hydrophilic modification method of polyacrylic ester

A polyacrylate, hydrophilic modification technology, applied in a method and the products obtained by the method, in the field of super-macroporous polyacrylate materials, can solve the problem of protein irreversible adsorption, Denaturation and other problems, to achieve the effect of reducing non-specific adsorption and improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

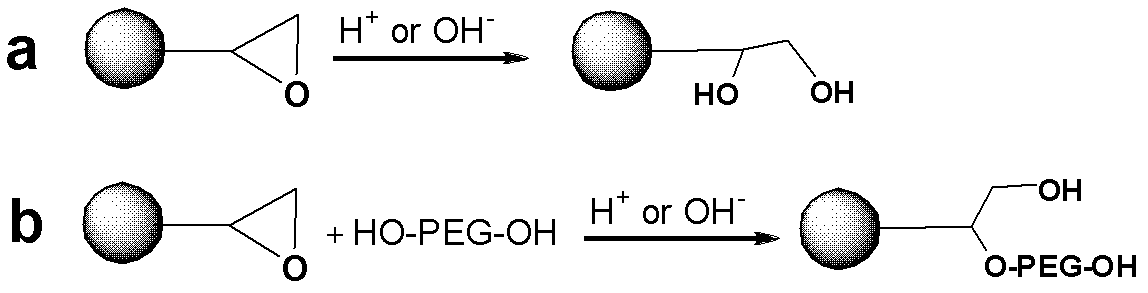

Method used

Image

Examples

Embodiment 1

[0039] 1) Super-macroporous PGMA-DVB microspheres are pretreated in dioxane

[0040] Accurately weigh 1.0 g of PGMA-DVB microspheres into a 50 mL Erlenmeyer flask, then add 10 mL of dioxane, shake at room temperature on a 120 rpm shaking shaker for 2 hours, perform suction filtration, and use the same volume of dioxane After washing, the solvent is suction-filtered until there is no obvious solvent on the surface of the microspheres.

[0041] 2) Agarose bound to the surface of PGMA-DVB microspheres (Mw=13W)

[0042] Weigh 1.0g of agarose (Mw=13W) and 0.32g of NaOH into a 100mL three-neck flask, then add 50mL of DMSO / H2O (1:5; v / v) mixed solvent to it, stir mechanically at 120rpm, and add the Step 1) Swell the treated microspheres, raise the temperature to 70°C, and keep the reaction at this temperature for 24 hours. After the reaction is hot, use a G4 sand core funnel to carry out vacuum filtration, and at the same time use 500mL of 80°C hot water to filter washing.

[0043...

Embodiment 2

[0046] 1) Pretreatment of ultra-large pore PGMA-DVB microspheres in DMSO

[0047] Accurately weigh 1.0 g of PGMA-DVB microspheres into a 50 mL Erlenmeyer flask, then add 20 mL of DMSO, shake at room temperature on a 120 rpm shaking shaker for 2 hours, perform suction filtration, and wash with the same volume of DMSO. After washing, the solvent Suction filtration until there is no obvious solvent on the surface of the microspheres.

[0048] 2) Dextran bound to the surface of PGMA-DVB microspheres (Mw=2W)

[0049] Weigh 1.0g dextran (Mw=2W), 0.32g NaOH into a 100mL three-neck flask, and then add 50mL DMSO / H 2 O (1:5, v / v) mixed solvent, under mechanical stirring at 120rpm, add the microspheres after swelling treatment in step 1) in Example 2, heat up to 37°C, and keep the reaction at this temperature for 20h. After the reaction, Suction filtration under reduced pressure with a G4 sand core funnel while hot, and at the same time wash with 500 mL of 40°C deionized water.

[005...

Embodiment 3

[0053] 1) Pretreatment of ultra-large pore PGMA-DVB microspheres in DMF

[0054] Accurately weigh 1.0 g of PGMA-DVB microspheres into a 50 mL Erlenmeyer flask, then add 15 mL of DMF, shake at room temperature on a 120 rpm shaking shaker for 2 hours, perform suction filtration, and wash with the same volume of DMF. After washing, the solvent Suction filtration until there is no obvious solvent on the surface of the microspheres.

[0055] 2) Dextran bound to the surface of PGMA-DVB microspheres (Mw=5W)

[0056] Weigh 1.0g dextran (Mw=5W), 0.32g NaOH and put it into a 100mL three-necked flask, then add 50mL DMSO / H2O (1:5, v / v) mixed solvent therein, under 120rpm mechanical stirring, add the Step 1) Swell the microspheres in Example 3, raise the temperature to 47°C, and keep the reaction at this temperature for 24 hours. Perform a wash.

[0057] 3) Reinforcing PGMA-DVB microsphere surface-bound dextran with EDGE cross-linking (Mw=5W)

[0058] The microspheres prepared in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com