Neutral low foam laundry detergent containing optical bleaching agent

A technology of optical bleaching agent and laundry detergent, applied in the direction of surface-active non-soap compounds and washing compositions, detergent compositions, chemical instruments and methods, etc., can solve the problem of large usage, insignificant low-temperature bleaching effect, and low bleaching efficiency and other problems, to achieve the effect of less foam, easy to rinse, whitening and brightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

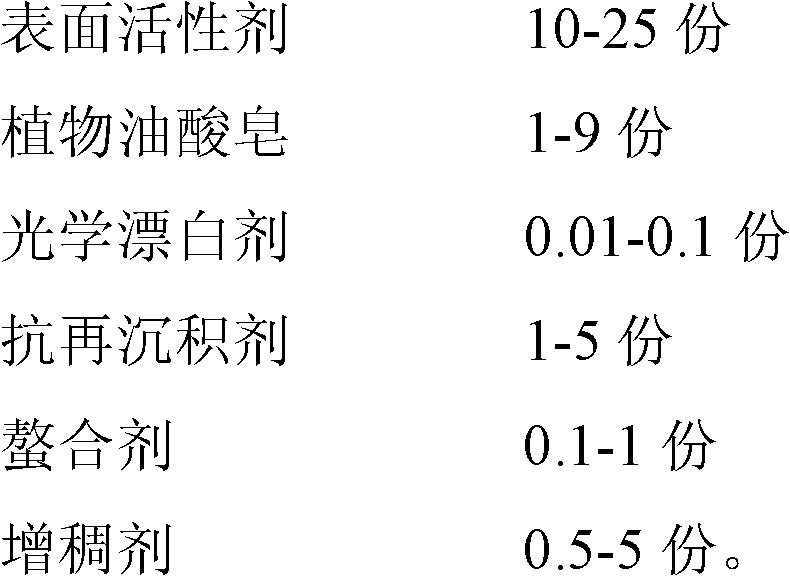

[0019] A neutral low-foaming laundry detergent containing optical bleach, its components and parts by mass are:

[0020]

[0021]

[0022] Above-mentioned optical bleaching agent is purchased from Ciba Company, model: BMC, sodium chloride as a thickener, disodium edetate as a chelating agent.

[0023] The preparation method of the neutral low-foaming laundry detergent containing optical bleach of embodiment 1 is as follows:

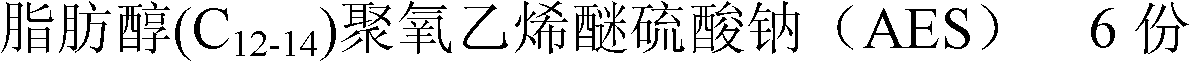

[0024] 1. Add in 76.58 parts of measured deionized water in turn, heat up to 60°C-70°C, stir while adding 6 parts of fatty alcohol polyoxyethylene ether sodium sulfate (AES), 3 parts of alkyl glucoside (APG), 2 parts of coconut Oleamidopropyl betaine (CAB), 2 parts of fatty alcohol polyoxyethylene (9) ether, 5 parts of ricinoleic acid soap, stirred to dissolve.

[0025] 2. Cool down to below 30°C, add 0.02 parts of optical bleaching agent, 3 parts of polyacrylic acid sodium salt, 0.1 part of disodium edetate, 0.1 part of essence, 0.2 parts of 2-m...

Embodiment 2

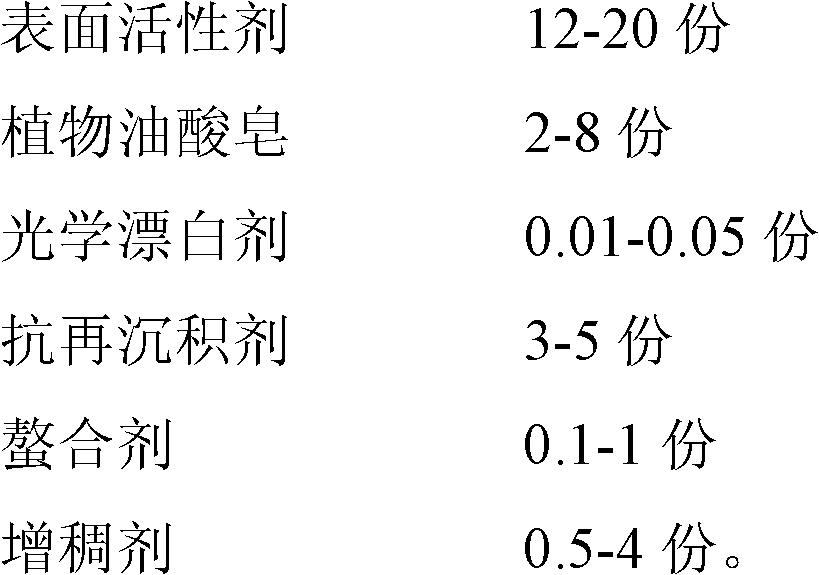

[0028] According to the same preparation method as in Example 1, the neutral low-foaming laundry detergent containing optical bleach is prepared with the following main active components and parts by mass:

[0029]

[0030]

[0031] Above-mentioned, optical bleaching agent is purchased from Ciba Company, model: BMC, sodium chloride as thickener, sodium citrate as chelating agent.

[0032] The present invention compares with performance of detergent containing hydrogen peroxide

[0033] Select Example 2 and compare the decontamination performance of commercially available hydrogen peroxide-containing laundry detergent. The coffee stained cloth whose whiteness has been measured in advance is soaked in two kinds of washing baths and exposed to the sun. After 1 hour, the coffee stain removal effect is obvious. After rinsing and drying, Then measure the whiteness of the stained cloth. The difference between the front and back whiteness reflects the decontamination ability. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com