Method of improving ginsenoside extraction rate by utilizing steam-explosion combined bio-composite enzyme technology

A biological compound enzyme and ginsenoside technology, applied in biochemical equipment and methods, enzymes, hydrolytic enzymes, etc., can solve the problem of low extraction rate of ginsenoside, achieve the effect of increasing extraction rate, reducing interference, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

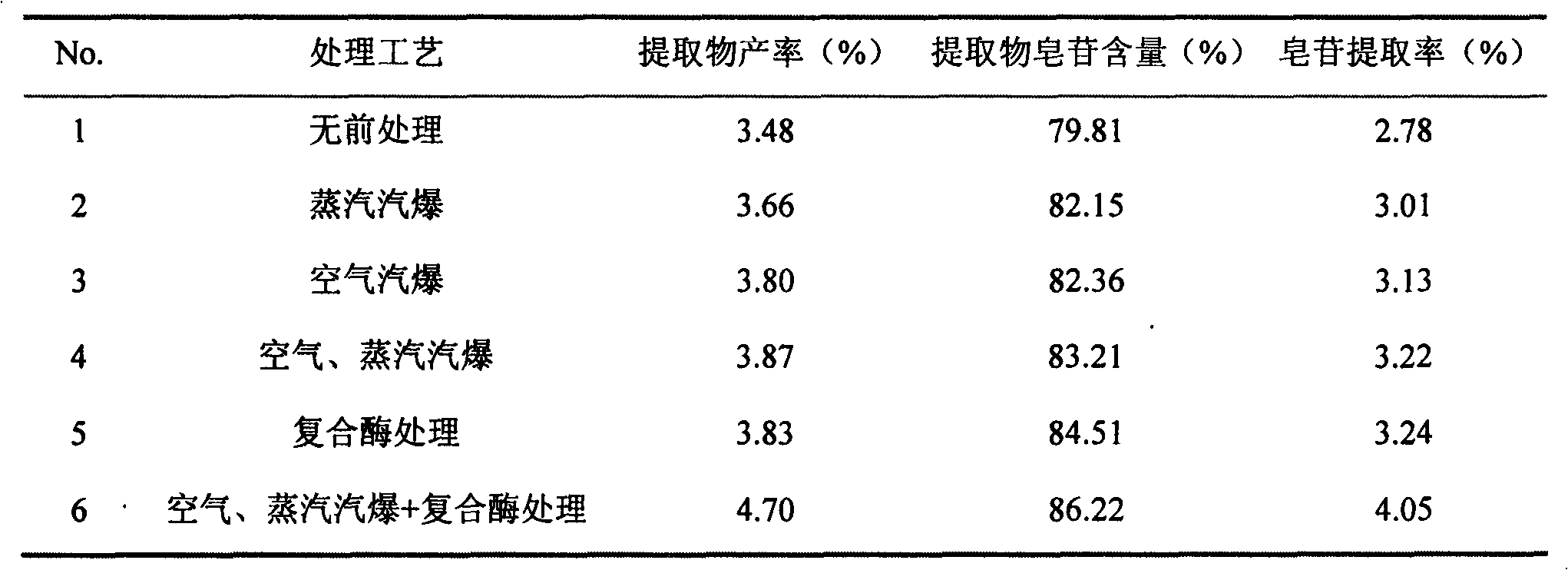

Image

Examples

Embodiment 1

[0030] (1) Raw material pre-treatment: wash the raw sun-dried ginseng with water to remove impurities such as silt, and then pulverize it;

[0031] (2) Steam explosion treatment: put the pre-treated ginseng in the steam explosion tank, first feed air until the pressure in the steam explosion tank is 1.0MPa, and blast for 10 minutes; then quickly pass steam into the steam explosion tank The pressure is 1.5MPa, steam explosion treatment for 1 minute;

[0032] (3) Biological compound enzyme treatment: Suspend the raw material after steam explosion with 5 times the amount of water, add biological compound enzyme preparation (25% of cellulase, 15% of pectinase, α-starch 30% enzyme, 15% protease, 15% laccase), hydrolysis at pH 7, 50°C for 2 hours;

[0033] (4) Extraction of ginsenosides: add 15 times the amount (based on the initial raw ginseng drying parameters) of 95% ethanol to the reaction system obtained after the treatment in (3), perform ultrasonic extraction for 45 minutes,...

Embodiment 2

[0036] (1) Pre-treatment of raw materials: wash the aboveground part of American ginseng to remove impurities such as sediment and then pulverize it;

[0037] (2) Steam explosion treatment: put the pre-treated raw materials in the steam explosion tank, first feed air until the pressure in the steam explosion tank is 0.8MPa, and blast for 15 minutes; then quickly pass steam into the steam explosion tank The pressure is 1.5MPa, steam explosion treatment for 2 minutes;

[0038](3) Biological compound enzyme treatment: Suspend the raw material after steam explosion with 10 times the amount of water, add biological compound enzyme preparation (30% of cellulase, 10% of pectinase, α-starch 35% enzyme, 10% protease, 15% laccase), hydrolysis at pH 7, 50°C for 2 hours;

[0039] (4) Extraction of ginsenosides: add 10 times the amount of water (based on the amount of the aerial part of American ginseng) to the reaction system obtained in (3), heat and reflux for extraction for 1 hour, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com