Distribution type infrared online temperature measurement system for electric terminals of high-voltage equipment

A technology for electrical contacts and high-voltage equipment, applied in the field of distributed infrared online temperature measurement systems, can solve the problems of inability to monitor equipment temperature online in real time, high-voltage arc breakdown, complex distribution, etc., to achieve integrated power supply and information processing, improve resistance Impact ability, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

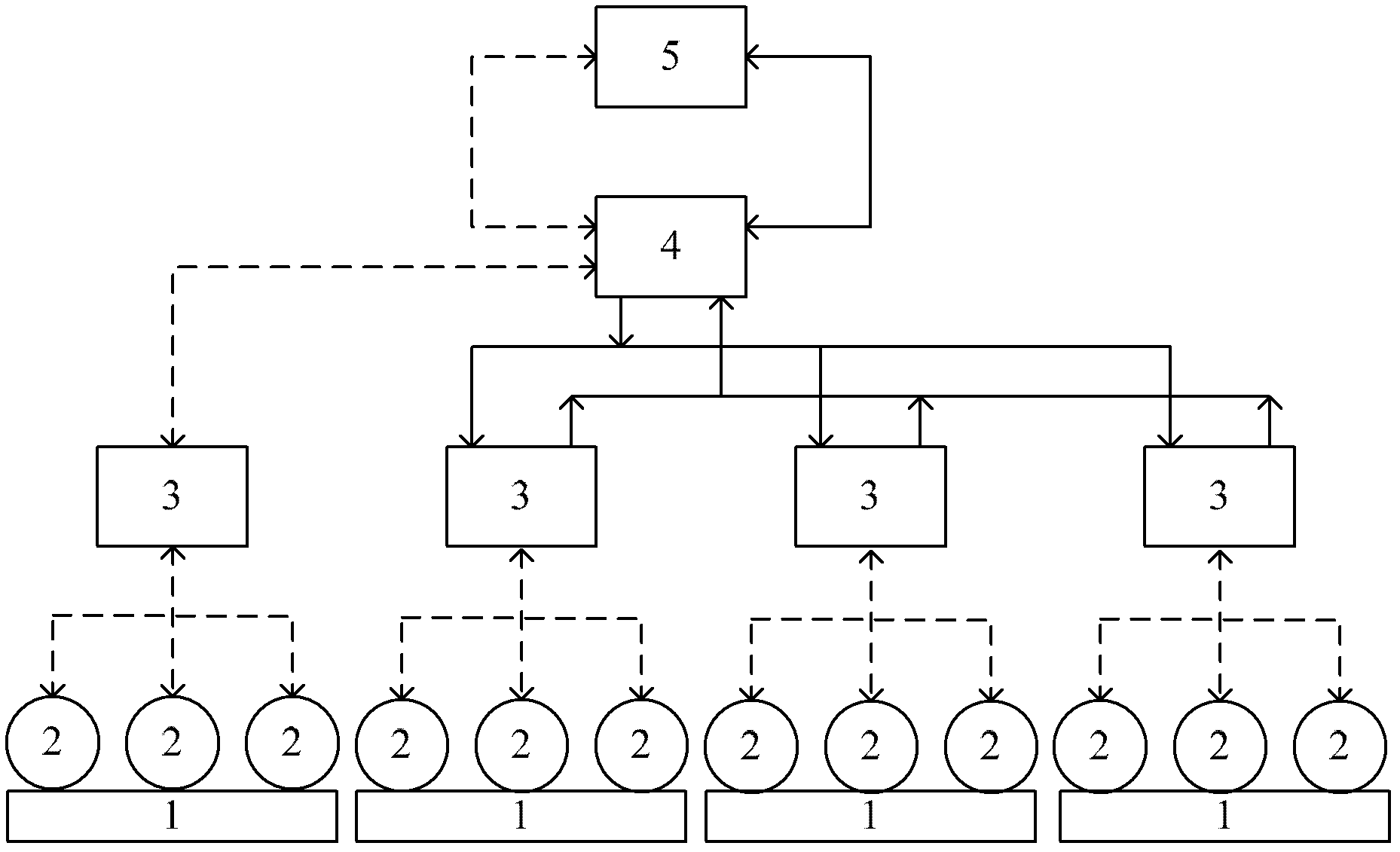

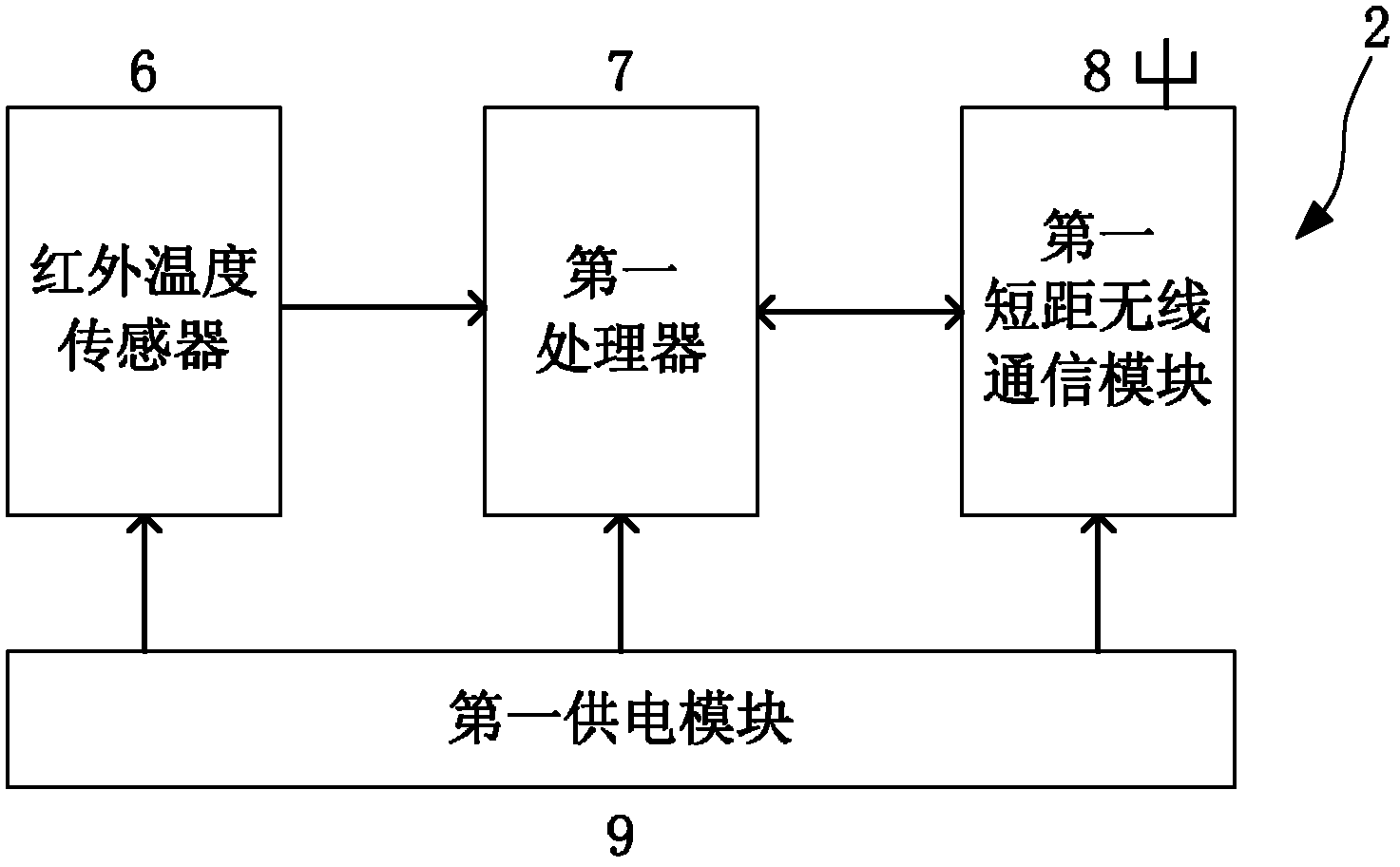

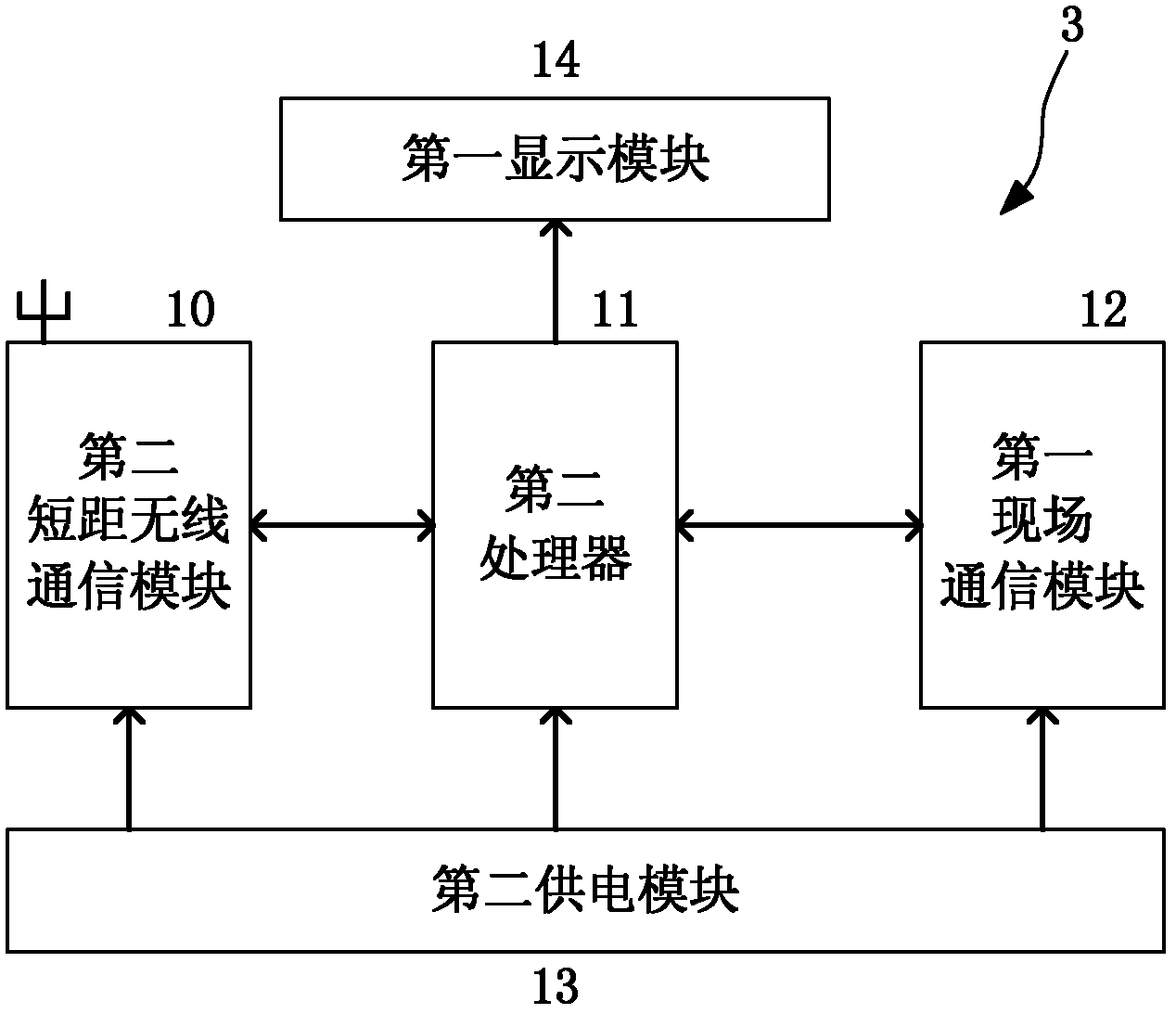

[0044] see figure 1 , the distributed infrared online temperature measurement system for electrical contacts of high-voltage equipment includes several groups of temperature sensing modules 2 , multiple secondary base stations 3 , a primary base station 4 and a remote control terminal 5 . Among them, the temperature sensing module 2 is installed at the electrical contacts of power distribution and transformation high-voltage equipment such as transformers, switch cabinets, switches, cables, etc., and at other set temperature monitoring points 1; the secondary base station 3 can receive signals within its communication range. The temperature information and alarm information and other data sent by the temperature sensing module 2 are forwarded to the primary base station 4; the remote control terminal 5 It is used to receive data such as temperature information and alarm i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com